Ultra-precision machining method of thin-wall complex structure monocrystal diamond inertial navigation device

A single crystal diamond, ultra-precision machining technology, used in metal processing equipment, manufacturing tools, laser welding equipment, etc., can solve the problems of low guidance accuracy and poor surface quality, and achieve improved guidance accuracy, rapid prototyping, and smoothness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

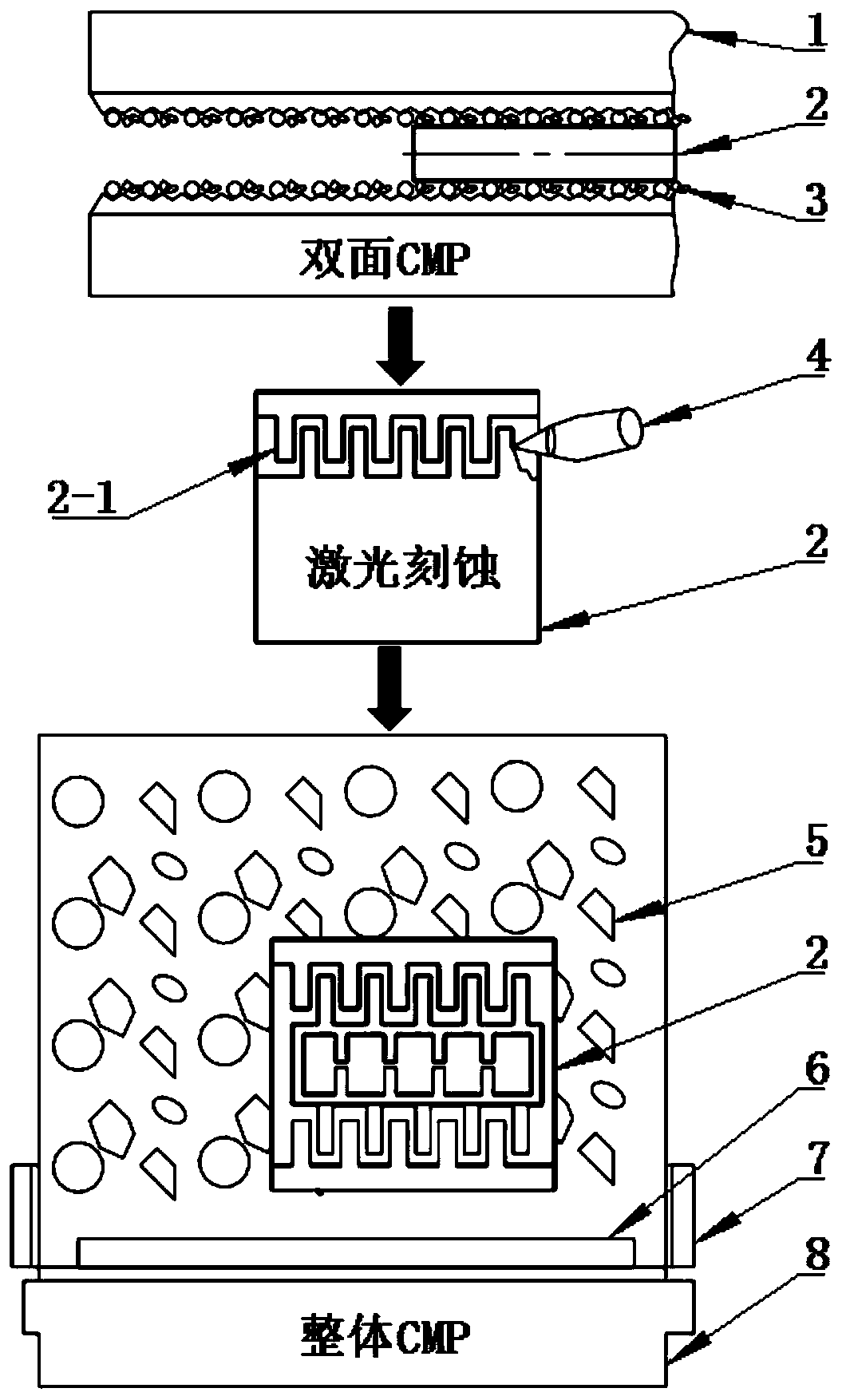

[0017] like figure 1 As shown, an ultra-precision machining method for a single-crystal diamond inertial navigation device with a thin-walled complex structure includes the following steps:

[0018] Step 1, use double-sided polishing machine 1 to carry out double-sided polishing to single crystal diamond inertial navigation device 2 (be blank at this moment), during polishing, drop polishing liquid A3; 5μm, zirconia abrasive with a content of 95g / L, sodium persulfate with a content of 55g / L, ursolic acid with a content of 85g / L, and deionized water for the rest;

[0019] Step 2, using the five-axis linkage picosecond laser 4 to etch the morphology structure 2-1 of the inertial navigation device 2 on the polished single crystal diamond inertial navigation device 2 substrate, and further modifying the shape by the femtosecond laser 4; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com