Preparation method of adsorption type demulsifier for oil-water separation of cleaning waste liquid

An oil-water separation and adsorption technology, which is applied in the field of polymer material preparation, can solve the problem of non-adsorption of the oil phase, and achieve the effect of easy operation and simple formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a preparation method of adsorption-type demulsifier microspheres for cleaning waste liquid oil-water separation, including:

[0027] A) Using solid polymethylsilsesquioxane microspheres (PSQ) as a template, a porous silica layer is coated on the surface by emulsion method to obtain PSQ@FS microspheres;

[0028] B) Surface functional modification of PSQ@FS microspheres with a silane coupling agent containing C=C;

[0029] C) The surface of the modified porous PSQ@FS microspheres obtained in step B is grafted with polyether polyquaternary ammonium salt (PPA) to obtain adsorption-type demulsifier microspheres (PSQ@FS@PPA) for cleaning waste liquid oil-water separation .

[0030] The preparation method of the adsorption type demulsifier microspheres for cleaning waste liquid oil-water separation provided by the present invention firstly coats the surface of the PSQ solid microspheres with a loose porous silica layer, and then couples with C=C-containing silan...

Embodiment 1

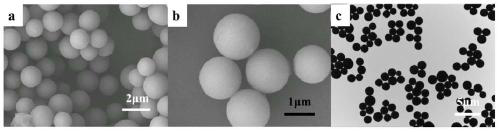

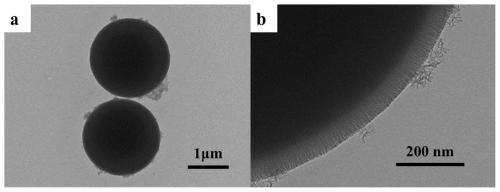

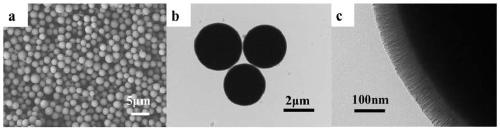

[0055] Preparation of PSQ@FS: Weigh 5g CTAB into a 500mL round-bottom flask, add 150mL deionized water, and then add 3g TEA and 5g PSQ microspheres for 20min ultrasonic dispersion. Add 150 mL of cyclohexane under magnetic stirring at room temperature, transfer 10 mL of TEOS into the above system with a pipette, and place it in a 70°C oil bath under magnetic stirring (800 rpm) for 4 hours after magnetic stirring for 30 minutes. After the reaction, the system was transferred to several 50mL centrifuge tubes, centrifuged at 3000rpm for 3min, collected the separated products, washed with industrial ethanol, centrifuged, repeated 3 times, and finally placed the products in a 55°C blast drying oven to dry. Finally, PSQ@FS microsphere powder is obtained. The morphology of the product was observed with a transmission electron microscope (TEM) (Hitachi H-7650, 100kV), such as figure 2 Shown. figure 2 These are TEM (a, b) photos of porous PSQ@FS microspheres prepared by the template me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com