Modified asphalt viscosity reducer and preparation method thereof

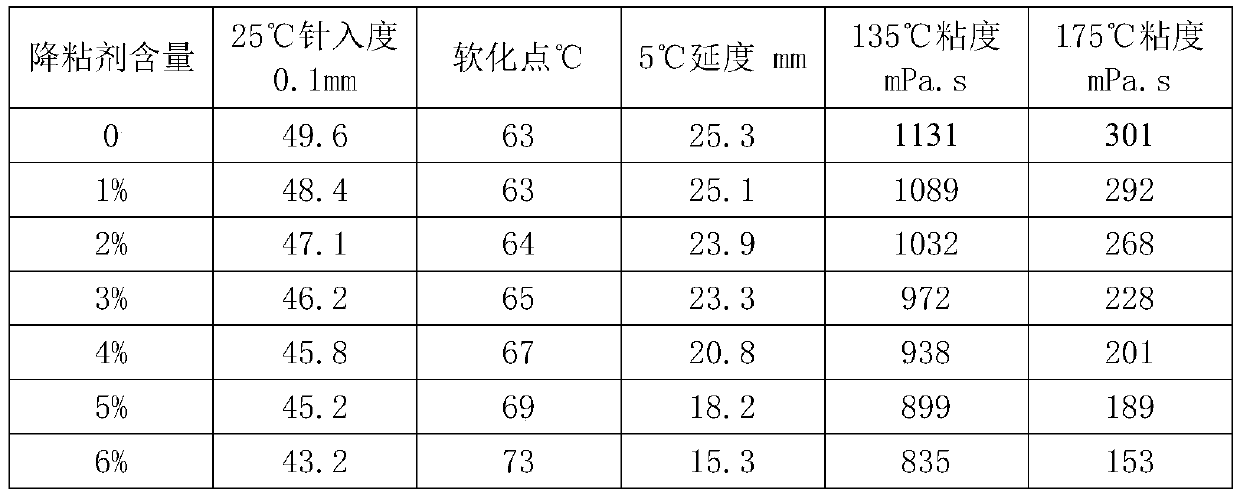

A technology of modified asphalt and viscosity reducer, which is applied to building components, building insulation materials, buildings, etc., can solve the problem that the viscosity reduction performance of modified asphalt needs to be optimized, and achieves improved peeling resistance, simple preparation method, and reduced high temperature. The effect of viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A modified asphalt viscosity reducer, the raw material of which is composed of 30 parts by weight of oxidized polyethylene wax, 10 parts of montan wax, 5 parts of iron stearate, 3 parts of zeolite powder and 2 parts of compatibilizer. In this embodiment: the oxidized polyethylene wax is a low molecular weight ethylene-vinyl acetate copolymer containing carbonyl groups, the molecular weight is 3000-4000, the iron element content of iron stearate is 6.0-7.0%, and the loss on drying is less than 1%. The melting point of zeolite is 80-85°C, and the particle size of zeolite powder is 400-600 mesh.

[0020] In the present embodiment, the preparation method of the modified asphalt viscosity reducer is as follows, and the specific steps include: step 1, first mix 10kg2.2.4-trimethyl 1.3-pentanediol diisobutyrate with 10kg dioctyl phthalate Put it into a 50L wide-mouth container and stir for 20min to prepare a mixture compatibilizer; then place 30kg of zeolite powder in a horizo...

Embodiment 2

[0026] A modified asphalt viscosity reducer, the raw material of which is composed of 20 parts by weight of oxidized polyethylene wax, 4 parts of montan wax, 1 part of iron stearate, 1 part of zeolite powder and 1 part of compatibilizer. In this embodiment: the oxidized polyethylene wax is a low molecular weight ethylene-vinyl acetate copolymer containing carbonyl groups, the molecular weight is 3000-4000, the iron element content of iron stearate is 6.0-7.0%, and the loss on drying is less than 1%. The melting point of zeolite is 80-85°C, and the particle size of zeolite powder is 400-600 mesh.

[0027] In the present embodiment, the preparation method of the modified asphalt viscosity reducer is as follows, and the specific steps include: step 1, first mix 5kg2.2.4-trimethyl 1.3-pentanediol diisobutyrate with 5kg dioctyl phthalate Put it into a 50L wide-mouth container and stir for 20min to prepare the mixture compatibilizer; then place 10kg of zeolite powder in a horizontal...

Embodiment 3

[0029] A modified asphalt viscosity reducer, the raw material of which is composed of 40 parts by weight of oxidized polyethylene wax, 20 parts of montan wax, 10 parts of iron stearate, 10 parts of zeolite powder and 5 parts of compatibilizer. In this embodiment: the oxidized polyethylene wax is a low molecular weight ethylene-vinyl acetate copolymer containing carbonyl groups, the molecular weight is 3000-4000, the iron element content of iron stearate is 6.0-7.0%, and the loss on drying is less than 1%. The melting point of zeolite is 80-85°C, and the particle size of zeolite powder is 400-600 mesh.

[0030] In the present embodiment, the preparation method of the modified asphalt viscosity reducer is as follows, and the specific steps include: step 1, first mix 25kg2.2.4-trimethyl 1.3-pentanediol diisobutyrate with 25kg dioctyl phthalate Put it into a 100L wide-mouth container and stir for 20min to prepare the mixture compatibilizer; then place 100kg of zeolite powder in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com