A kind of uv white primer for electrostatic spraying and preparation method thereof

An electrostatic spraying, white technology, used in primers, coatings, polyester coatings, etc., can solve the problems of heavy surface grinding work, affecting the appearance quality of the paint film, waste, etc., to achieve excellent anti-sag performance, improve The effect of anti-sag properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

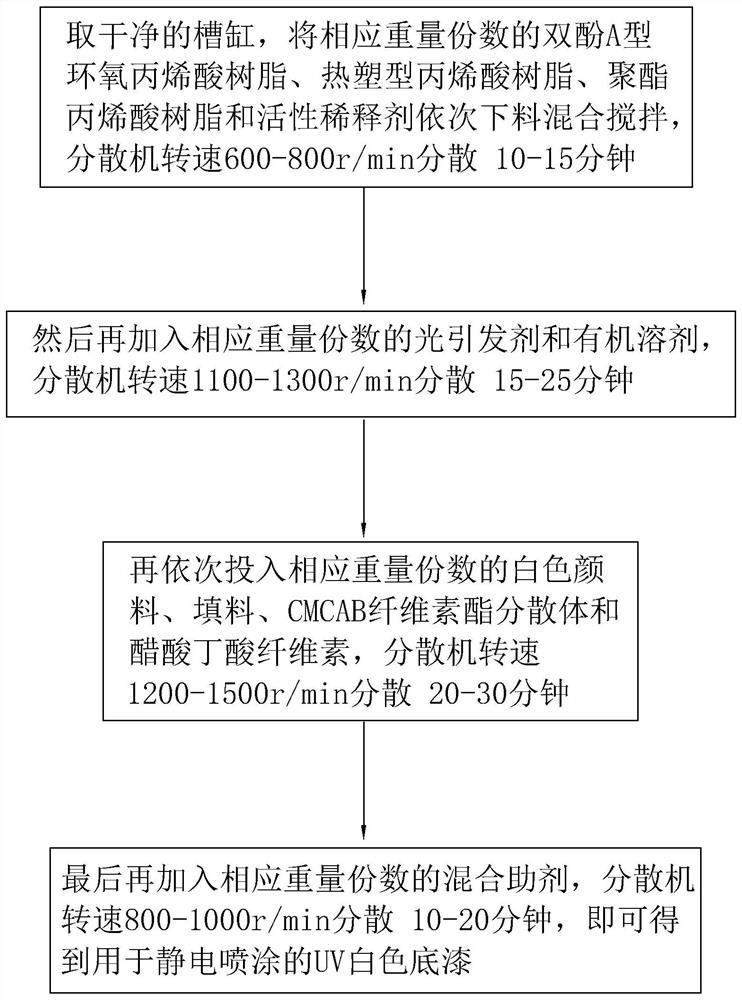

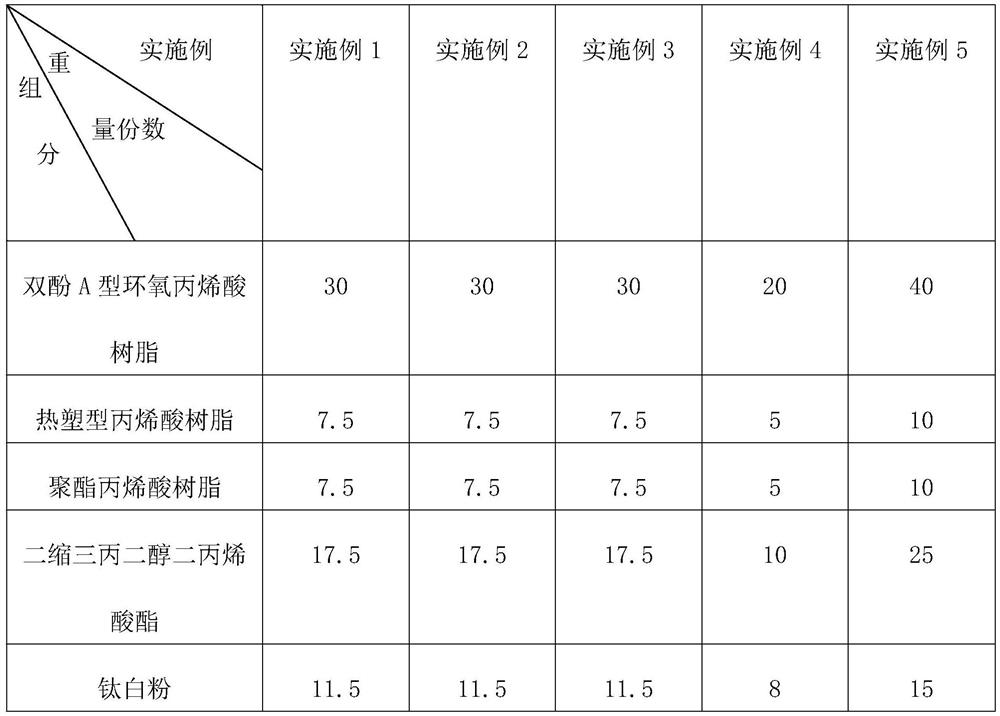

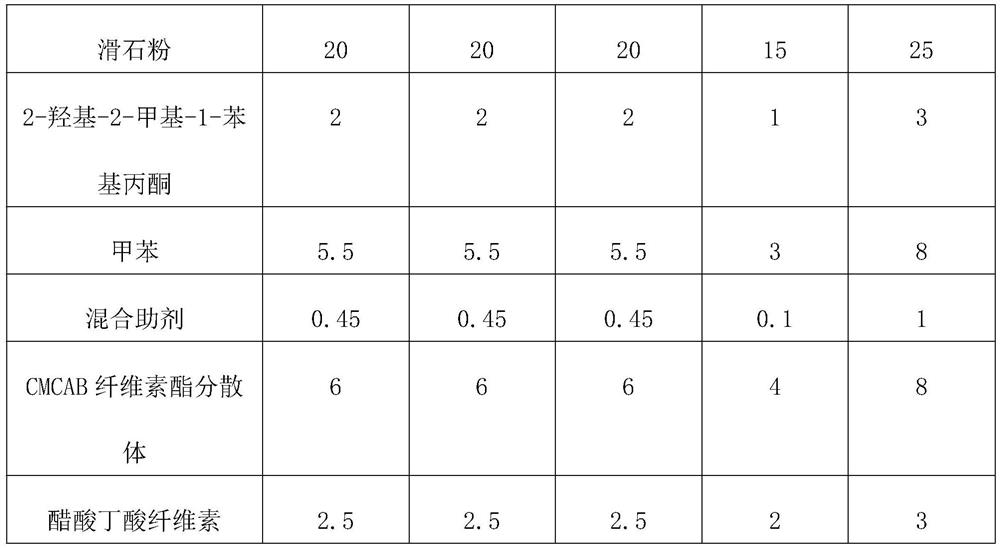

[0049] Embodiment 1: A UV white primer for electrostatic spraying, each component and its corresponding parts by weight are shown in Table 1, and are prepared through the following steps:

[0050] Step 1, take a clean vat, mix and stir the bisphenol A type epoxy acrylic resin, thermoplastic acrylic resin, polyester acrylic resin and tripropylene glycol diacrylate of the corresponding parts by weight in sequence, Disperse at 700r / min for 12.5 minutes;

[0051] Step 2, then add 2-hydroxyl-2-methyl-1-phenylacetone and toluene in corresponding parts by weight, and disperse for 20 minutes at a speed of 1200r / min of the disperser;

[0052] Step 3, then input titanium dioxide, talcum powder, CMCAB cellulose ester dispersion and cellulose acetate butyrate in corresponding parts by weight, and disperse for 25 minutes at a disperser speed of 1350r / min;

[0053] Step 4: Finally, add the mixing aid in corresponding parts by weight, and disperse for 15 minutes at the speed of the disperse...

Embodiment 2

[0055] Embodiment 2: a kind of UV white primer for electrostatic spraying, the difference with embodiment 1 is, mainly comprises the following steps:

[0056] Step 1, take a clean vat, mix and stir the bisphenol A type epoxy acrylic resin, thermoplastic acrylic resin, polyester acrylic resin and tripropylene glycol diacrylate of the corresponding parts by weight in sequence, Disperse at 600r / min for 15 minutes;

[0057] Step 2, then add 2-hydroxyl-2-methyl-1-phenylacetone and toluene in corresponding parts by weight, and disperse for 25 minutes at a disperser speed of 1100r / min;

[0058] Step 3, then input titanium dioxide, talcum powder, CMCAB cellulose ester dispersion and cellulose acetate butyrate in corresponding parts by weight, and disperse for 20 minutes at a disperser speed of 1500r / min;

[0059] Step 4: Finally, add the mixing auxiliary agent in corresponding parts by weight, and disperse for 10 minutes at the rotational speed of the disperser at 1000r / min, and then...

Embodiment 3

[0060] Embodiment 3: a kind of UV white primer for electrostatic spraying, the difference with embodiment 1 is, mainly comprises the following steps:

[0061] Step 1, take a clean vat, mix and stir the bisphenol A type epoxy acrylic resin, thermoplastic acrylic resin, polyester acrylic resin and tripropylene glycol diacrylate of the corresponding parts by weight in sequence, Disperse at 800r / min for 10 minutes;

[0062] Step 2, then add 2-hydroxyl-2-methyl-1-phenylacetone and toluene in corresponding parts by weight, and disperse for 15 minutes at a disperser speed of 1300r / min;

[0063] Step 3, then input titanium dioxide, talcum powder, CMCAB cellulose ester dispersion and cellulose acetate butyrate in corresponding parts by weight, and disperse for 30 minutes at a disperser speed of 1200r / min;

[0064] Step 4, finally add the mixing aid in corresponding parts by weight, and disperse for 20 minutes at the speed of the disperser at 800r / min to obtain a UV white primer for el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com