3D printing high-wear-resistance stainless steel material, preparation method and application of material

A 3D printing and stainless steel technology, applied in the direction of additive processing, etc., can solve the problems of large internal stress, poor wear resistance, large temperature gradient of formed parts, etc., and achieve small material deformation, good corrosion resistance, and good wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

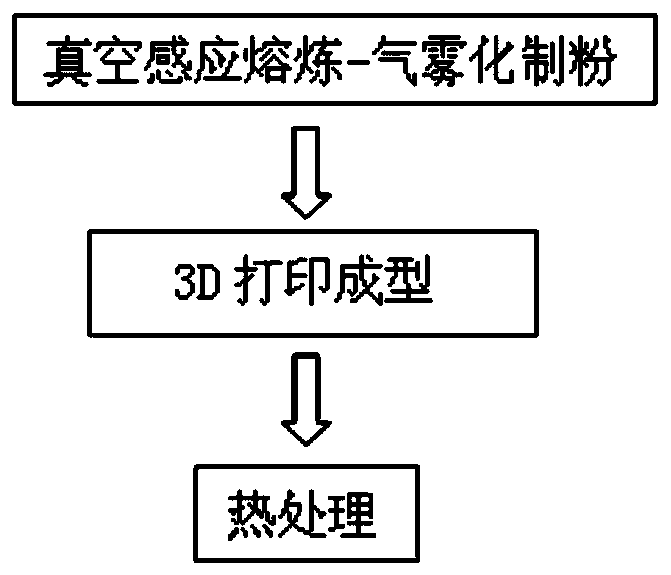

Method used

Image

Examples

Embodiment 1

[0019] A 3D printing high wear-resistant stainless steel material, including the powder of the following components:

[0020] Chromium 12.5wt%, Nickel 8.1wt%, Molybdenum 2.5wt%, Aluminum 1.2wt%, Silicon 0.1wt%, Manganese 0.2wt%, Niobium 0.4wt%, Vanadium 0.3wt%, Titanium 0.1wt%, 0.02wt% nitrogen, 0.21wt% carbon, and the rest is iron.

[0021] The preparation method is:

[0022] Step 1: Weigh raw materials in proportion;

[0023] Step 2: The metal powder is produced by vacuum melting and gas atomization method; the melting temperature is 1550°C, the vacuum degree is 3Pa, and the atomization pressure is 3MPa; the powder shape obtained by vacuum melting and gas atomization method is spherical, and the powder particle size distribution is between 15- 53μm, the powder oxygen content is 600ppm.

[0024] Use the above 3D printing high wear-resistant stainless steel materials for 3D printing to manufacture molds:

[0025] Step a: Part Printing

[0026] Use 3D printing stainless st...

Embodiment 2

[0033] A 3D printing high wear-resistant stainless steel material, including the powder of the following components:

[0034] Chromium 11.8wt%, Nickel 8.3wt%, Molybdenum 2.3wt%, Aluminum 1.4wt%, Silicon 0.2wt%, Manganese 0.4wt%, Niobium 0.3wt%, Vanadium 0.4wt%, Titanium 0.2wt%, 0.02wt% nitrogen, 0.22wt% carbon, and the rest is iron.

[0035] The preparation method is:

[0036] Step 1: Weigh raw materials in proportion;

[0037] Step 2: The metal powder is produced by vacuum melting and gas atomization method; the melting temperature is 1530°C, the vacuum degree is 3Pa, and the atomization pressure is 3Mpa; the shape of the powder obtained by vacuum melting and gas atomization method is spherical, and the particle size distribution of the powder is between 15- 53μm, the powder oxygen content is 800ppm.

[0038] Use the above 3D printing high wear-resistant stainless steel materials for 3D printing to manufacture molds:

[0039] Step a: Part Printing

[0040] Use 3D printin...

Embodiment 3

[0047] A 3D printing high wear-resistant stainless steel material, including the powder of the following components:

[0048] Chromium 12.2wt%, nickel 7.6wt%, molybdenum 2.2wt%, aluminum 1.0wt%, silicon 0.1wt%, manganese 0.1wt%, niobium 0.5wt%, vanadium 0.1wt%, titanium 0.5wt%, 0.03wt% nitrogen, 0.23wt% carbon, and the rest is iron.

[0049] The preparation method is:

[0050] Step 1: Weigh raw materials in proportion;

[0051] Step 2: The metal powder is produced by vacuum melting and gas atomization method; the melting temperature is 1590°C, the vacuum degree is 3Pa, and the atomization pressure is 3MPa; the powder shape obtained by vacuum melting and gas atomization method is spherical, and the powder particle size distribution is between 15- 53μm, the powder oxygen content is 800ppm.

[0052] Use the above 3D printing high wear-resistant stainless steel materials for 3D printing to manufacture molds:

[0053] Step a: Part Printing

[0054] Use 3D printing stainless st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com