Three-dimensional vibration isolation device with sliding oblique springs

An oblique spring and vibration damping device technology, applied in the field of three-dimensional vibration isolation devices, can solve the problem that the vertical vibration of buildings and large and medium-sized equipment cannot be reduced, the vertical rigidity and horizontal rigidity cannot meet the structural requirements, and the support rigidity cannot be adapted. problem, to achieve the effect of clear three-way vibration isolation, reducing different frequencies and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

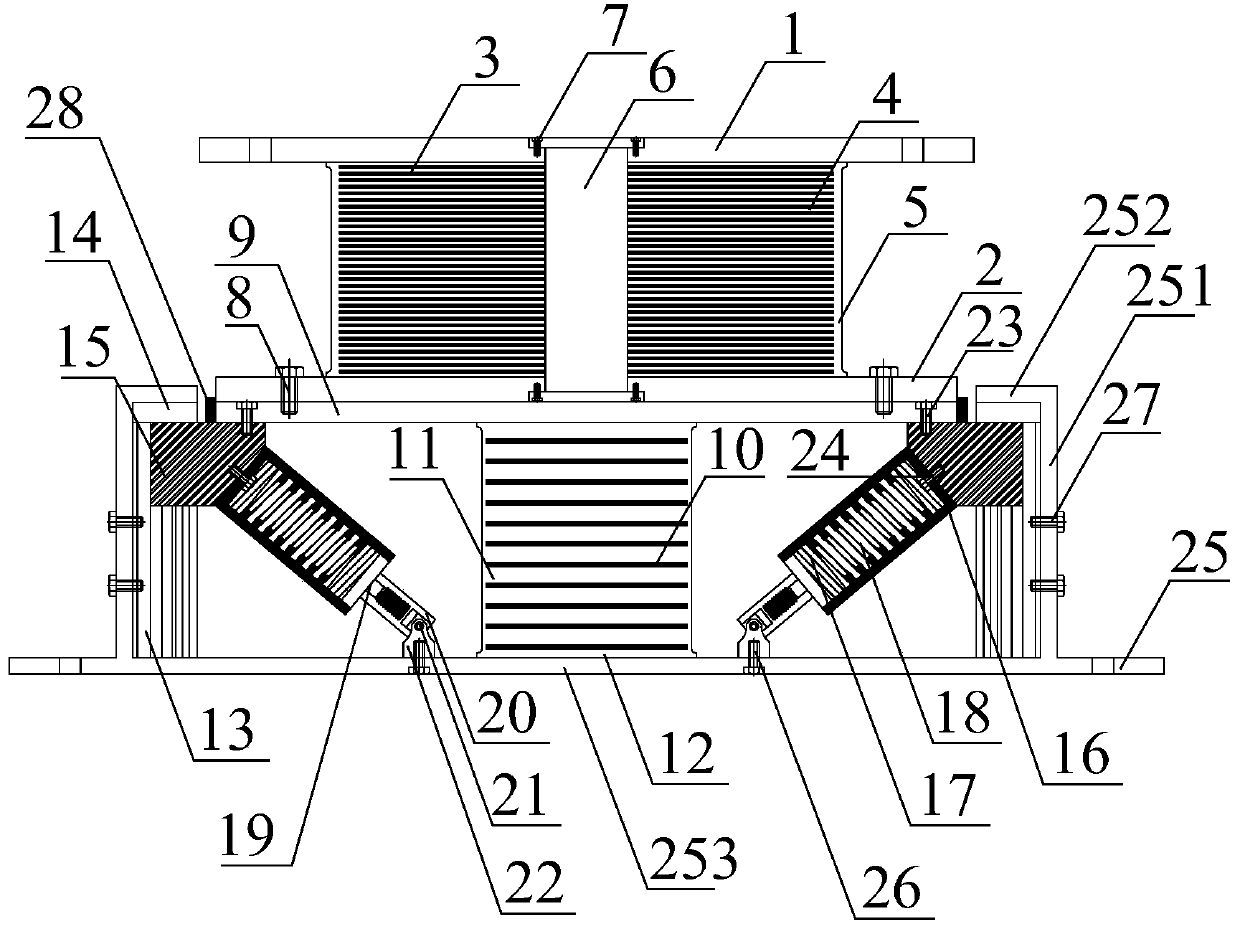

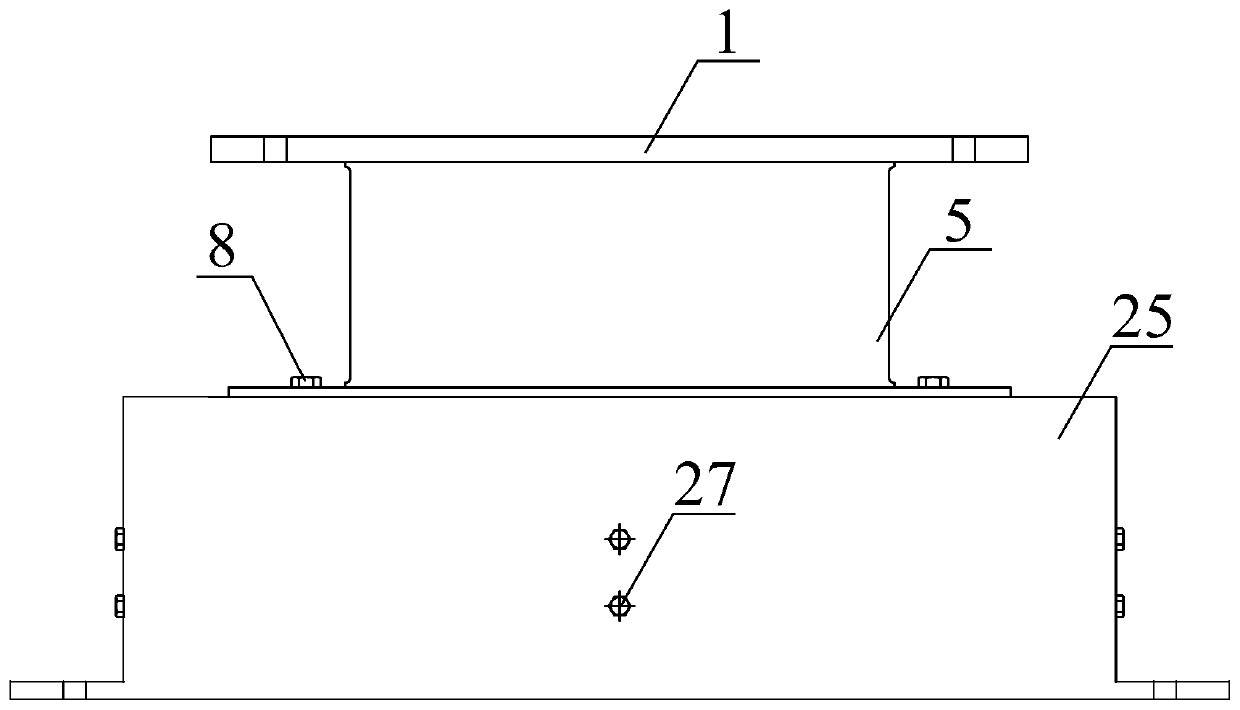

[0043] see figure 1 , figure 2 and image 3 , as an example only.

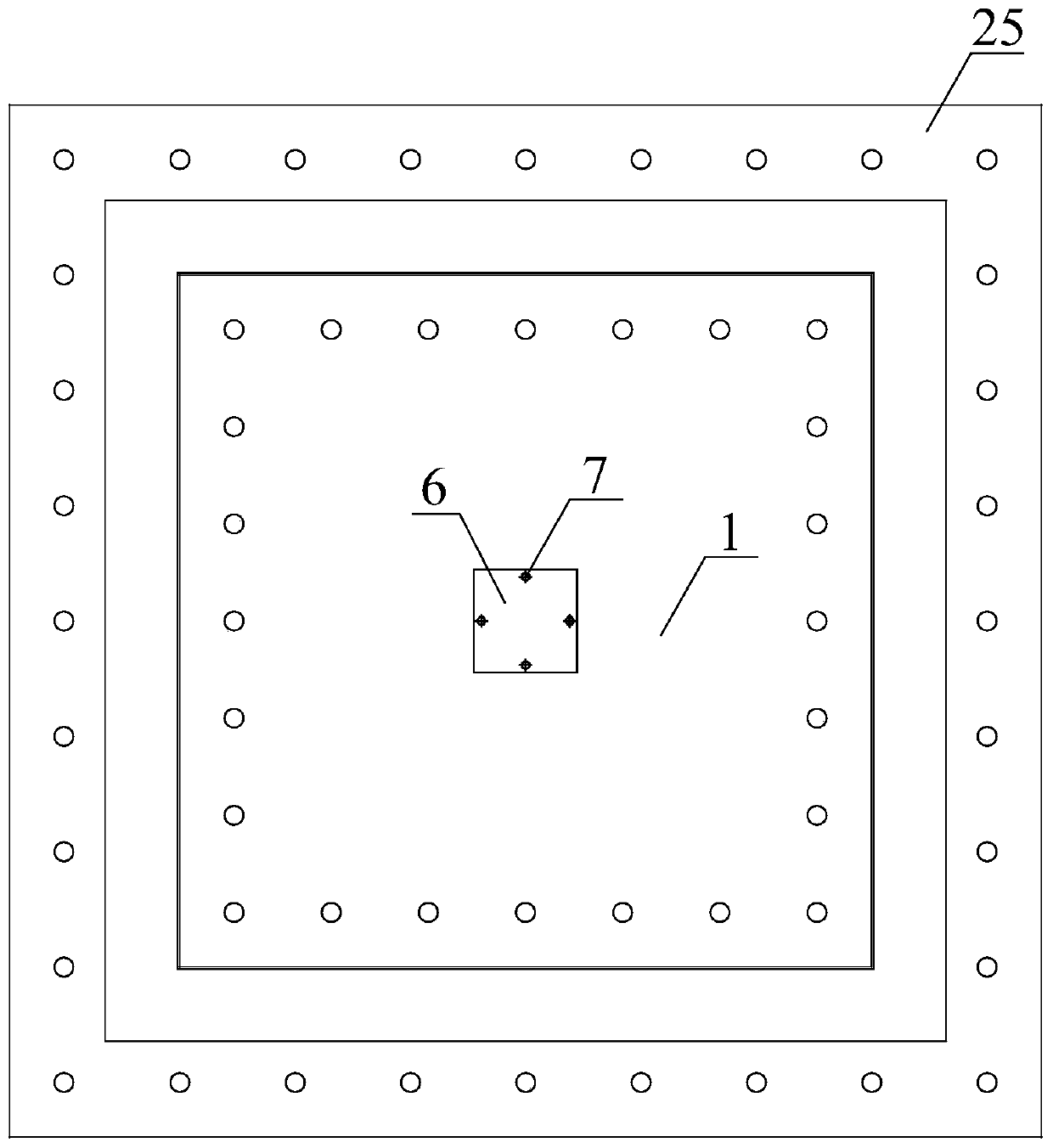

[0044] Figure 4 It is the top view of the vertical vibration isolation unit. In this embodiment, 4 sets of slidable rectangular compression spring devices are provided. Under the action of vertical vibration, 4 sets of slidable rectangular compression spring devices are linked together to reduce the vertical vibration. The 4 sets of devices are placed symmetrically to prevent excessive amplitude and Destabilize structure or equipment.

[0045] Figure 5 and Figure 6 It is a perspective view of a slidable rectangular compression spring device. The vertical slider 15 moves downward, and the kinetic energy is converted into the elastic potential energy of the rectangular compression spring 18, and then the rectangular compression spring 18 rebounds, and the elastic potential energy is converted into the kinetic energy of the vertical slider 15, and the vibration action time becomes longer and the ampli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com