High-damage-threshold liquid crystal optical panel with arbitrary depolarization compensation and exposure device thereof

A high-damage-threshold, liquid crystal optics technology, applied in photoplate-making process exposure devices, microlithography exposure equipment, optics, etc., can solve the problems of low damage threshold, complex structure, and high performance requirements of laser heads, and achieves simple structure, high performance, etc. The effect of precision exposure processing and high aperture ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

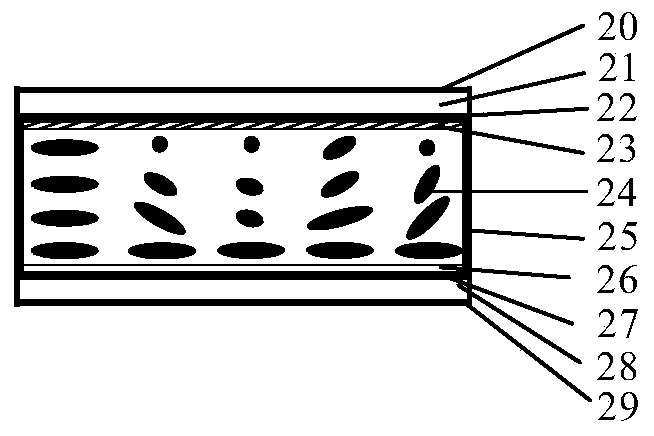

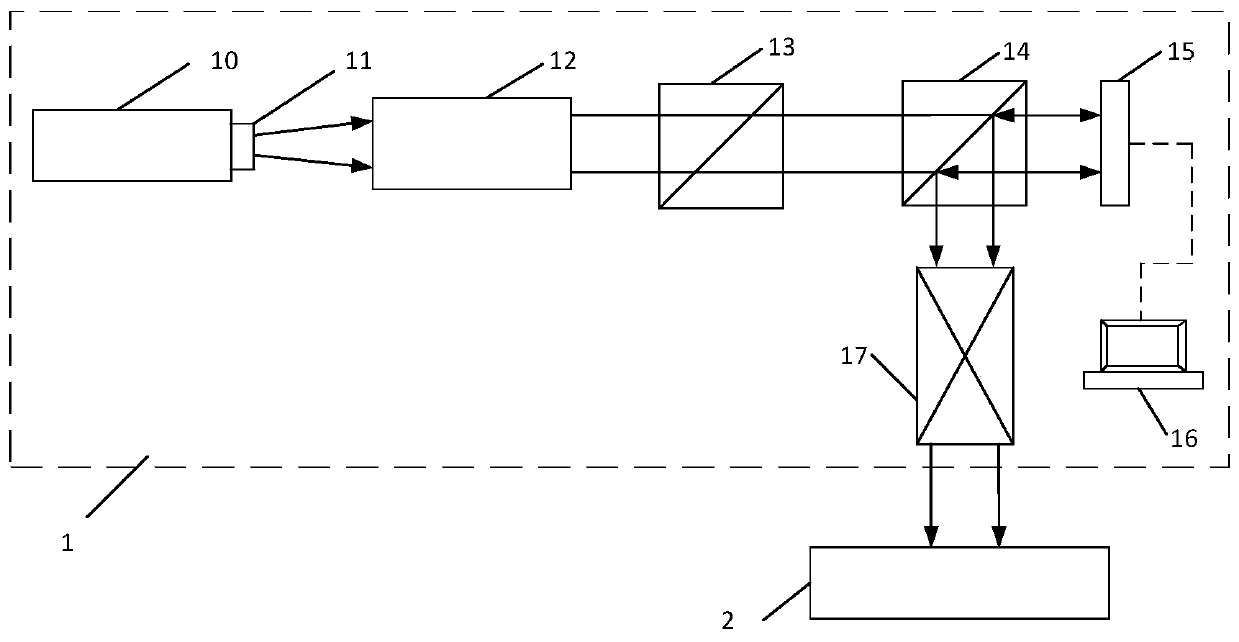

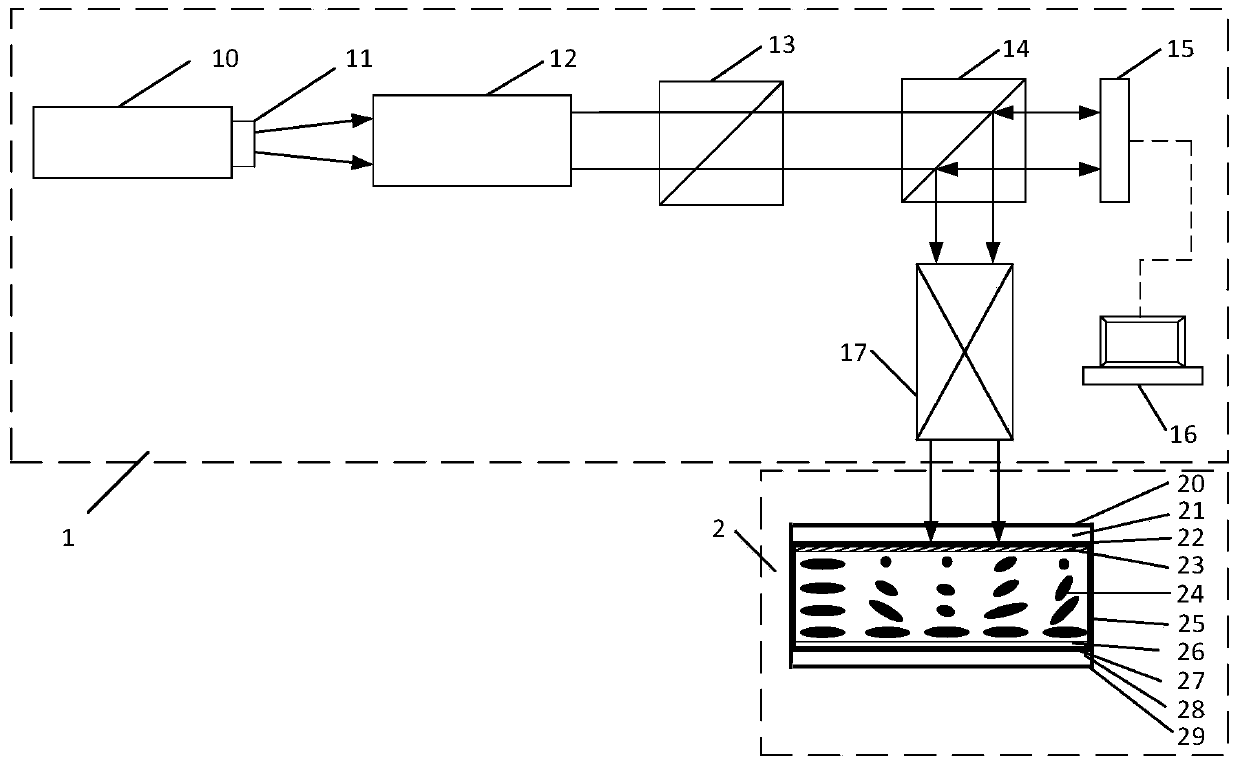

[0030] A high damage threshold liquid crystal optical panel with arbitrary depolarization compensation, which is used for arbitrary polarization state degradation compensation of high-power lasers. The present invention consists of a liquid crystal optical panel 2 and an exposure device 1 for depolarization compensation. Among them, the liquid crystal optical panel 2 is composed of a first dielectric film layer 20, a first glass substrate 21, a second dielectric film layer 22, a light control alignment film layer 23, a liquid crystal layer 24, a spacer frame glue 25, a rubbing alignme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com