A kind of phosphonate hydrolysis device and method

A technology of phosphonic acid ester and dimethyl propyl phosphonate is applied in the field of methyl phosphonate hydrolysis device and phosphonate hydrolysis device, which can solve the problem of difficulty in the source of phosphonic acid, and achieves reduction of equipment investment, convenient operation, methanol high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

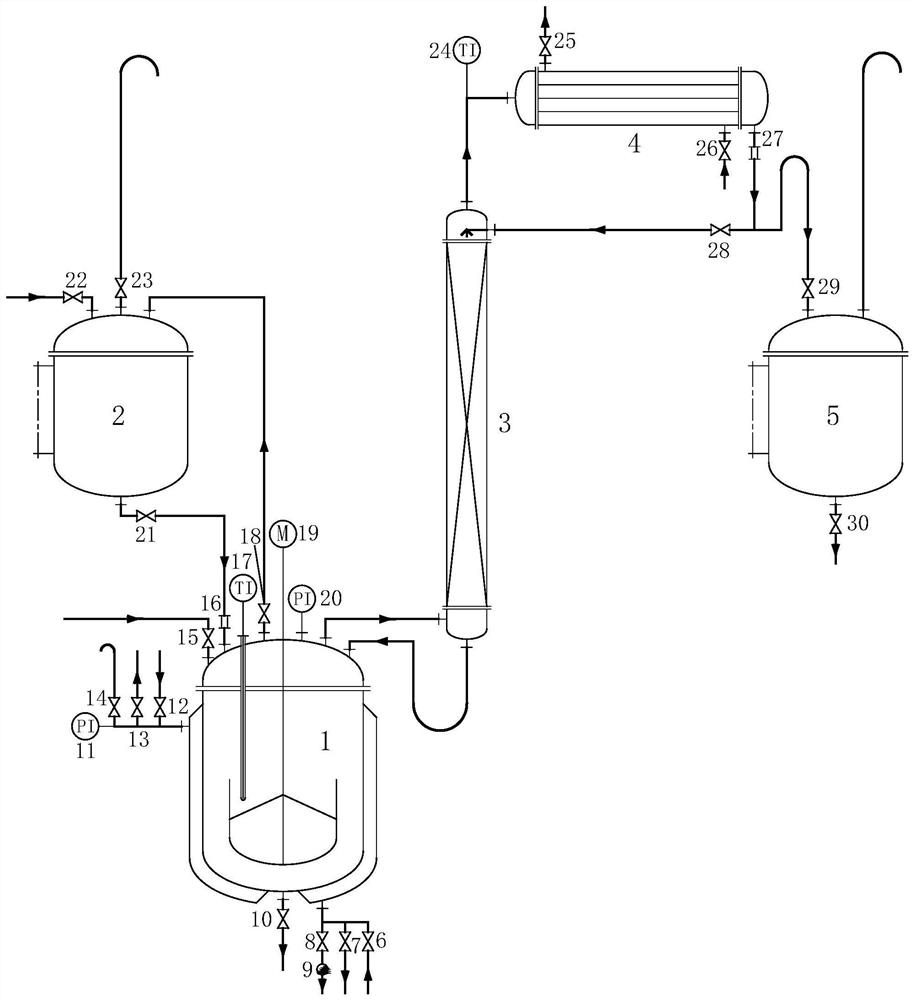

[0041] (1) Preparation: Check and confirm that the stirring motor 19, steam pressure gauge 11, kettle pressure gauge 20, kettle temperature thermometer 17, and top temperature thermometer 24 are in good condition, open the vent valve 23, fraction inlet valve 29, and check that other valves are in good condition. Closed state, open feeding valve 15, add 300kg methylphosphonic acid dimethyl ester and 75kg methylphosphonic acid catalyst (filling coefficient is 0.75, catalyst quantity is 20% of phosphonate mass) in hydrolysis kettle 1, close feeding valve 15. Open the water filling valve 22 to add 270L of process water to the head tank 2 (filling coefficient is 0.9), close the water filling valve 22, and check to confirm that the supply of steam and circulating water is normal;

[0042] (2) Hydrolysis: Open the circulating water inlet valve 26 and the circulating water outlet valve 25 of the condenser 4, feed the circulating water into the shell side of the condenser 4, close the v...

Embodiment 2

[0045] (1) Preparation: Check and confirm that the stirring motor 19, steam pressure gauge 11, kettle pressure gauge 20, kettle temperature thermometer 17, and top temperature thermometer 24 are in good condition, open the vent valve 23, fraction inlet valve 29, and check that other valves are in good condition. In the closed state, open the feeding valve 15 and add 280kg dimethyl propylphosphonate and 70kg propylphosphonic acid catalyst to the hydrolysis kettle 1 (the charging coefficient is 0.70, and the amount of catalyst is 25% of the mass of phosphonate), and close the feeding valve 15 , open the water filling valve 22 to add process water to the head tank 2 to 270L (filling coefficient 0.9), close the water filling valve 22, and check to confirm that the supply of steam and circulating water is normal;

[0046] (2) Hydrolysis: Open the circulating water inlet valve 26 and the circulating water outlet valve 25 of the condenser 4, feed the circulating water into the shell s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com