Separation method of butene hydroformylation reaction liquid effluent

The technology of a hydroformylation and separation method is applied in the field of separation of the liquid effluent of the butene hydroformylation reaction, which can solve the problem of high evaporation temperature and achieve the effects of high recovery rate, good separation and prolonged service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

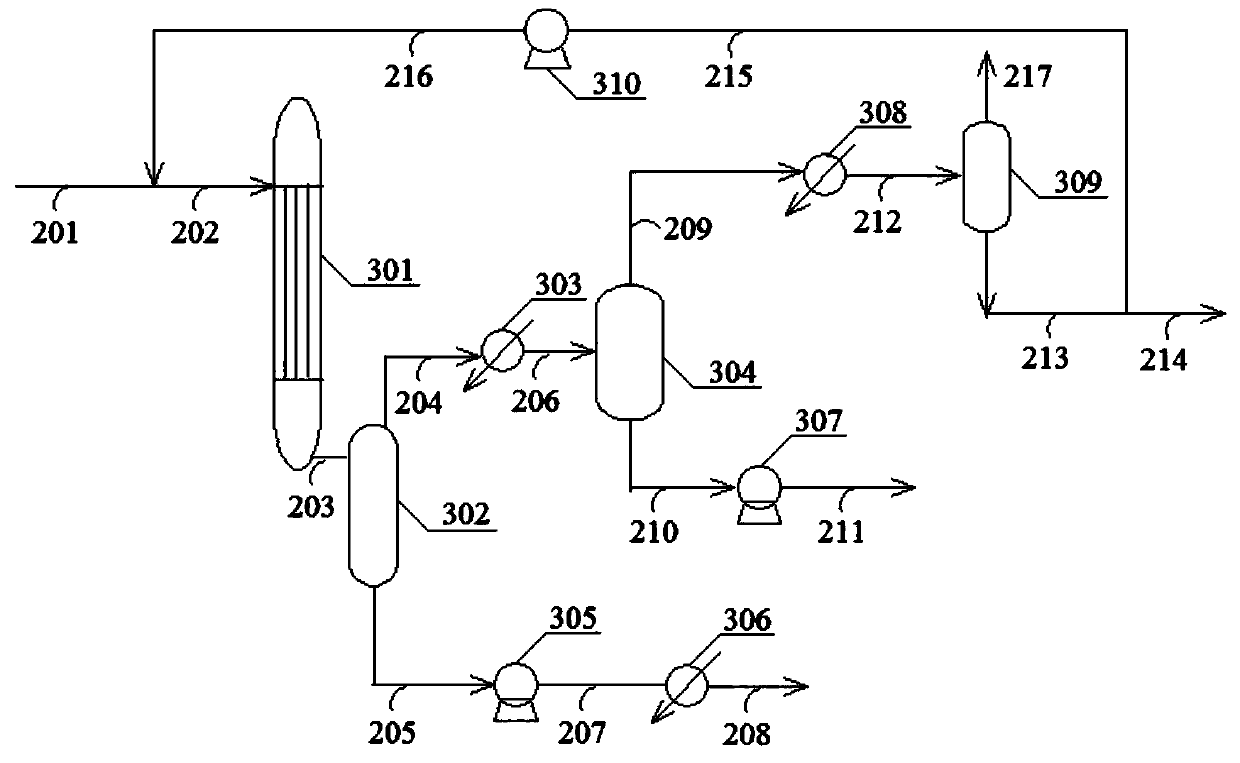

[0041] The reaction process of embodiment 1 is in such as figure 2 Carried out in the apparatus shown: Mixed butene hydroformylation reaction product stream from reactor (70°C-75°C, approximate composition: 5.7% butane, 6.3% trans-2-butene, cis-2-butene ene 2.1%, 1-butene 0.06%, n-valeraldehyde 53.5%, isovaleraldehyde 2.8%, high boiler 28.5%, bisphosphonite ligand catalyst (6,6'-[(3,3', 5,5'-Tetra-tert-butyl-1-1'-biphenyl) 2,2'-Dioxo]-bis-bibenzo[d,f][1,3,2]dioxaphosphorine ) 0.5%, rhodium 200ppm, and the rest are a small amount of synthesis gas, methane etc. dissolved in the liquid phase.) With the speed of 500g / hr through the pipeline 201 and from the rectifying tower 307 tower top and by the C of 540g / hr delivered by the pump 309 Reflux (35-40 ℃, approximate composition: 98.5% C4, 0.2% valeraldehyde, 1.2% methane) enters in thin-film evaporator 301 (0.12MPa, 100 ℃) together and evaporates, obtains concentrated rhodium-containing - a solution of bisphosphonite catalysts (...

Embodiment 2

[0043] The reaction process of embodiment 2 is also in such as figure 2 Carry out in the shown device: the experimental process of embodiment 2 is basically consistent with embodiment 1, and its feeding amount and composition through pipeline 201 are the same as embodiment 1, and difference is in the C4 stream that is recycled back to evaporator 301 through pipeline 215. The flow rate increased to 750g / hr, and the C4 stream extracted from the top of the rectifying tower 307 through the pipeline 216 was 70g / hr the same as in Example 1, and the amount of valeraldehyde extracted through the pipeline 213 at the bottom of the rectifying tower was 240g / hr . At this time, the evaporation temperature of the evaporator 301 drops to 95°C. The recovery rate of valeraldehyde is more than 87%, and the recovery rate of C4 is 94%.

Embodiment 3

[0045] The reaction process of embodiment 3 is in such as figure 2 Carried out in the device shown: isobutene hydroformylation reaction product stream from the reactor (90° C., approximate composition: 3.1% butane, 7.2% isobutene, 56.5% 3-methylbutanal, 27.7% high boilers, Triphenylphosphine ligand catalyst 5.1%, rhodium 200ppm, the rest is a small amount of synthesis gas, methane etc. dissolved in the liquid phase.) with the speed of 500g / hr through pipeline 201 and from rectifying tower 307 tower top and transported by pump 309 About 385g / hr of C4 reflux (35-40°C, approximate composition: 99% C4, 0.1% 3-methylbutyraldehyde, 0.5% methane) enters the thin film evaporator 301 (0.12MPa, 100°C) for evaporation , obtain the concentrated solution containing rhodium-triphenylphosphine catalyst from the bottom of evaporator 301 (approximate composition: high boiler 72.9%, 3-methylbutanal 12.2%, triphenylphosphine 13.4%, about 1.4% of C4, The remainder is trace methane, etc.), throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com