Refining method of high-purity cariprazine

A refining method and cariprazine technology, applied in the refining field of high-purity cariprazine, can solve problems such as by-product X being difficult to remove

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

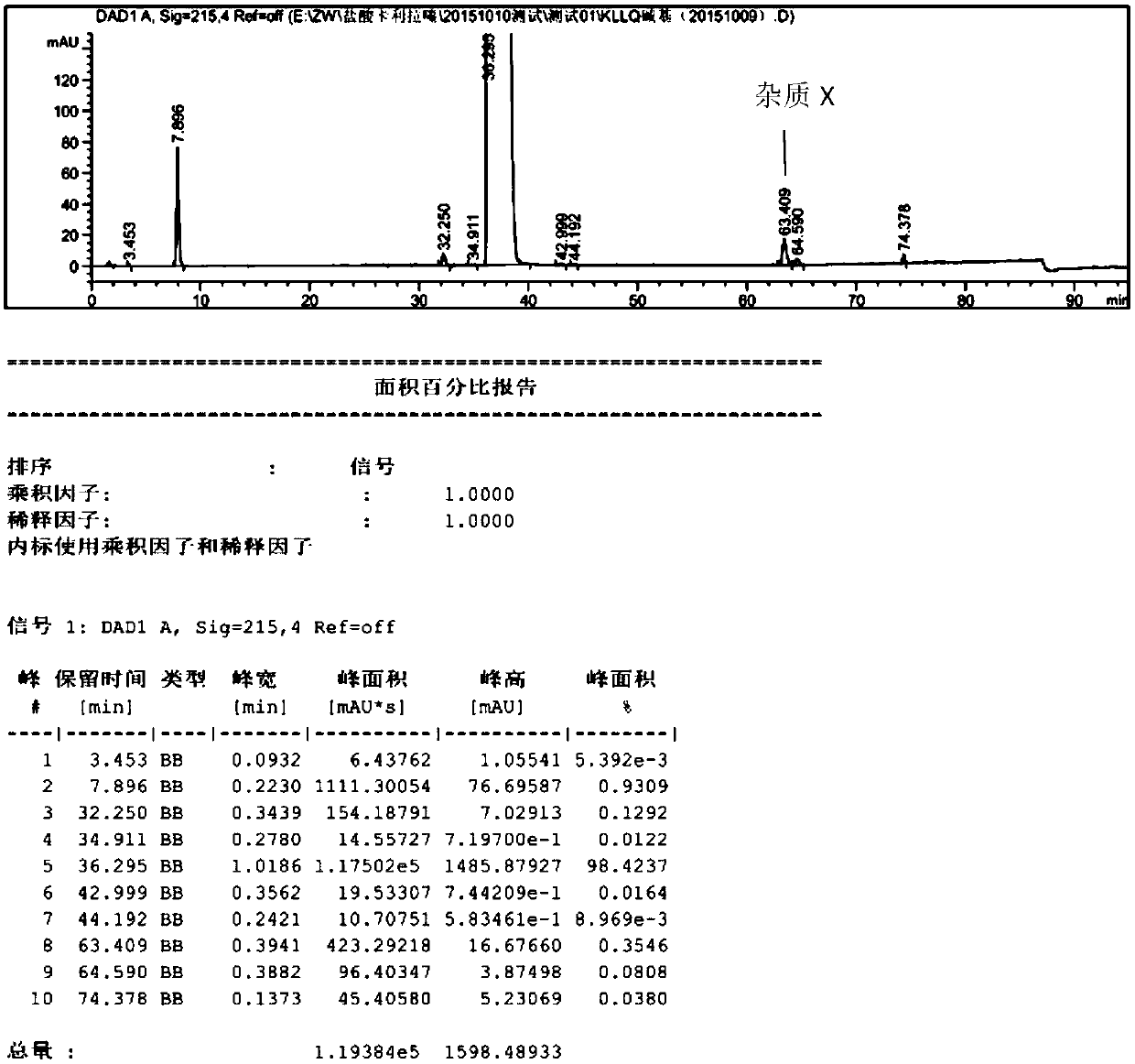

Problems solved by technology

Method used

Image

Examples

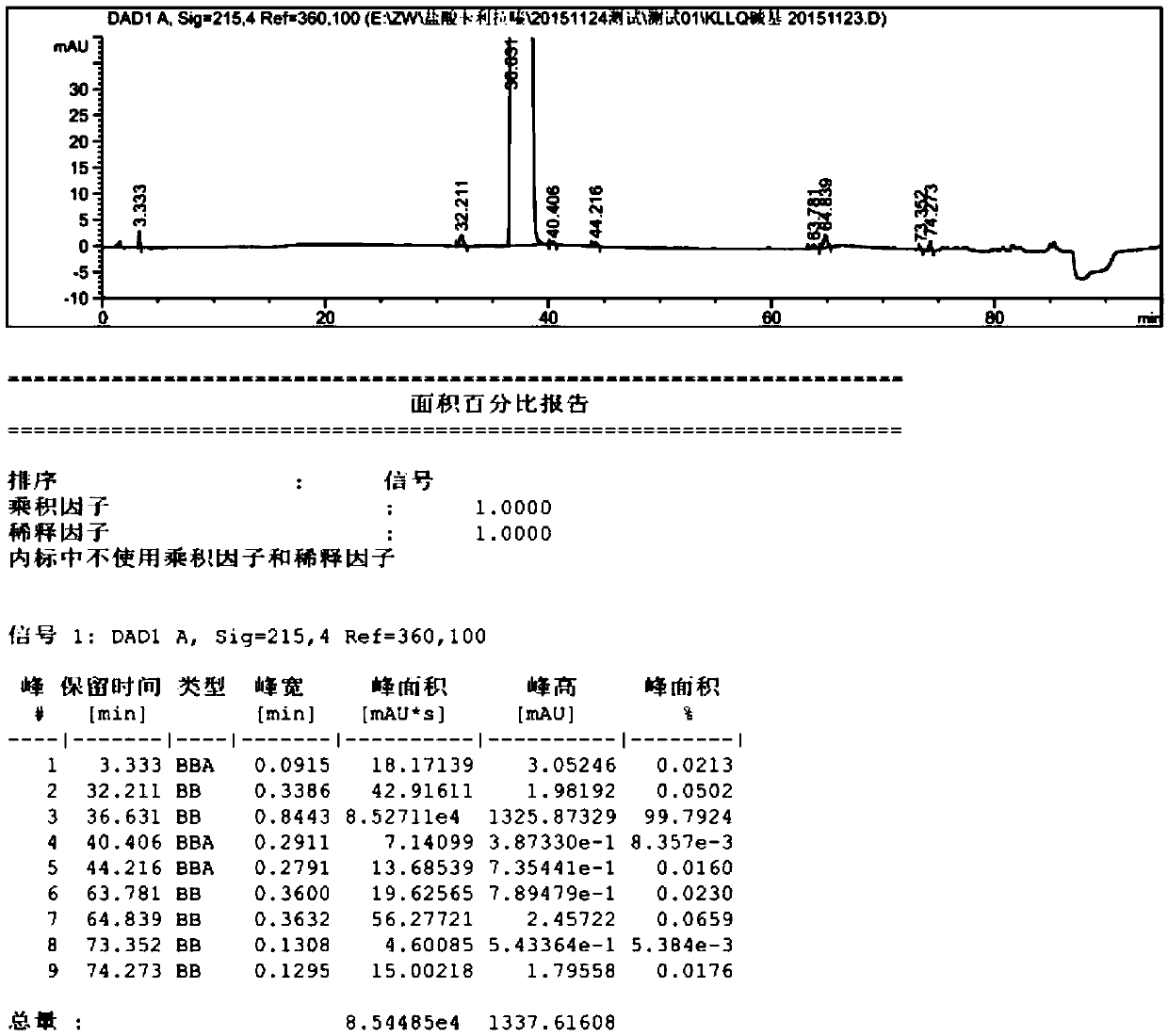

Embodiment 1

[0037] (1) Cariprazine crude product 10g is joined in the 250ml reaction bottle, add 50ml dichloromethane, 30ml ethanol, heat to reflux, make the solution clarification;

[0038] (2) Slowly add 75ml of ethyl acetate and stir for 20 minutes; slowly cool down to 30°C.

[0039] (3) Ice-water bath, cooled to 0-10°C, stirred for 3 hours;

[0040] (4) Filter, and wash the filter cake with 30ml ethyl acetate, and vacuum-dry to constant weight at 50°C to obtain 8.1g cariprazine crystals, yield 81%, purity (HPLC) 99.79, impurity X (63.78min) The content of 0.02%, such as figure 2 mentioned.

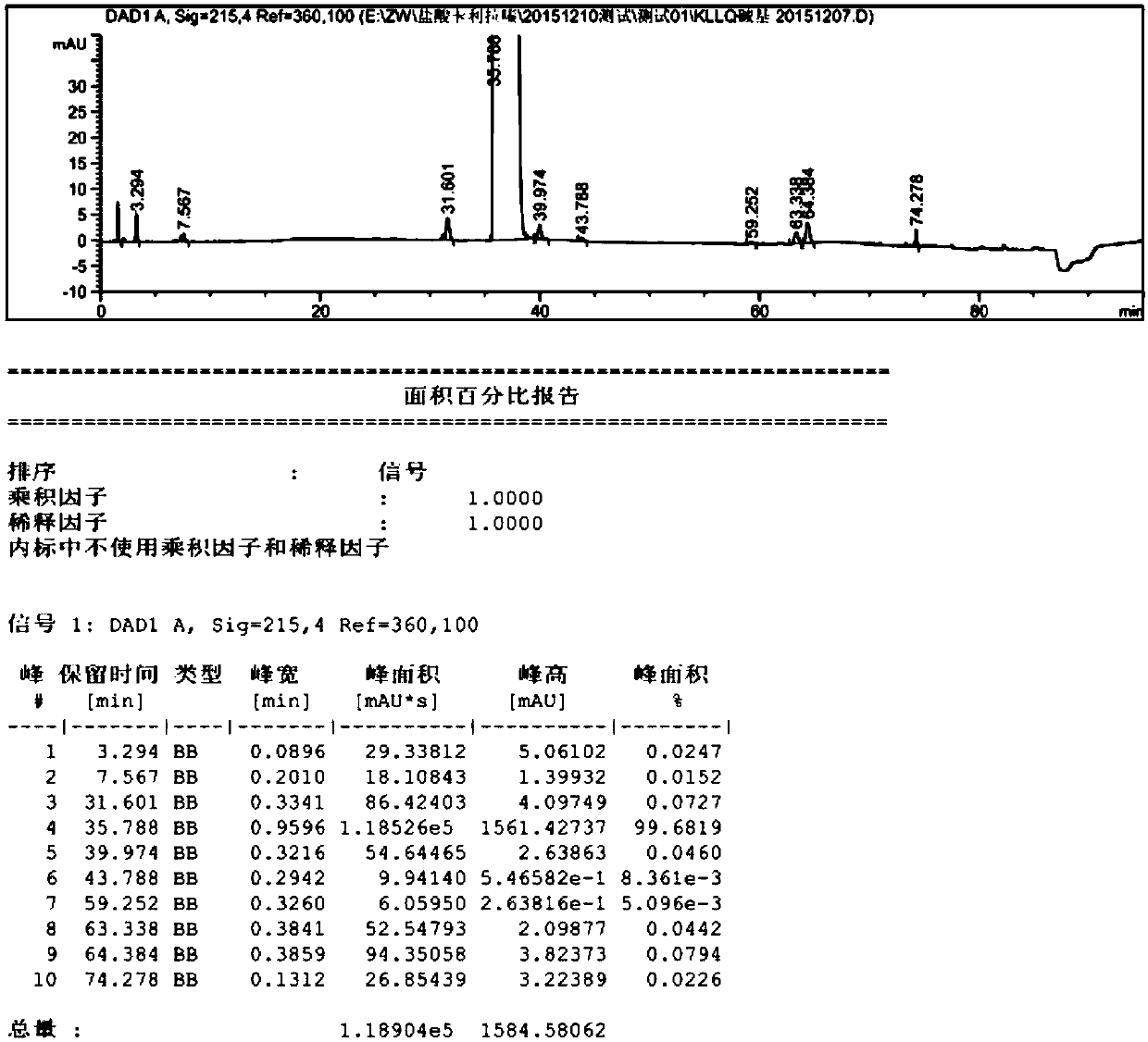

Embodiment 2

[0042] (1) Cariprazine crude product 10g is joined in 250ml reaction bottle, add 30ml dichloromethane, 70ml ethanol, heat to reflux, make solution clarification;

[0043] (2) Slowly add 75ml of ethyl acetate and stir for 20 minutes; slowly cool down to 30°C.

[0044] (3) Ice-water bath, cooled to 0-10°C, stirred for 5 hours;

[0045] (4) filter, and wash the filter cake with 15ml ethyl acetate, and vacuum-dry to constant weight at 50 ℃, obtain 8.4g cariprazine crystal, yield 84%, purity (HPLC) 99.68, impurity X (63.33min) The content of 0.04%, such as image 3 shown.

Embodiment 3

[0047] (1) Add 20 g of cariprazine crude product into a 500 ml reaction flask, add 40 ml of methylene chloride and 60 ml of ethanol, and heat to reflux to make the solution clear;

[0048] (2) Slowly add 100ml of ethyl acetate and stir for 20 minutes; slowly cool down to 30°C.

[0049] (3) Ice-water bath, cooled to 0-10°C, stirred for 3 hours;

[0050] (4) filter, and wash the filter cake with 30ml ethyl acetate, and vacuum-dry to constant weight at 50 ℃, obtain 17.1g cariprazine crystal, yield 85.5%, purity (HPLC) 99.88, the content of impurity X 0.02% ,Such as Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com