High-residual-strength phenolic flame-retardant system glass fiber reinforced plastic material and preparation method thereof

A technology of residual strength and glass fiber reinforced plastic, which is applied in the field of high residual strength phenolic flame retardant system glass fiber reinforced plastic material and its preparation field, can solve the problems of low residual strength at high temperature and easy to burn, and achieve high safety, good flame retardancy and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

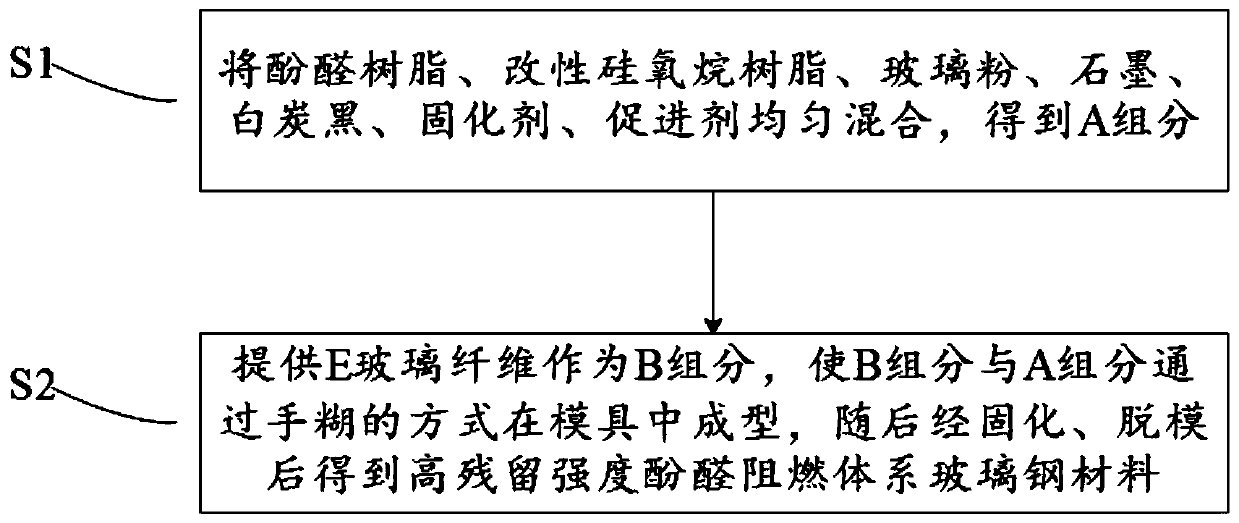

[0026] like figure 1 , the second aspect of the present invention provides a method for preparing a high residual strength phenolic flame retardant system FRP material, comprising the following steps:

[0027] S1: Evenly mix phenolic resin, modified siloxane resin, glass powder, graphite, white carbon black, curing agent and accelerator to obtain component A;

[0028] S2: Provide E glass fiber as component B, make component B and component A molded in the mold by hand lay-up, and then obtain high residual strength phenolic flame retardant system FRP material after curing and demoulding.

[0029] The preparation method of the high residual strength phenolic flame retardant system FRP material provided by the second aspect of the present invention is used to prepare the high residual strength phenolic flame retardant system FRP material provided by the first aspect of the present invention.

[0030] Preferably, the specific steps to obtain component A are:

[0031] (1) uniform...

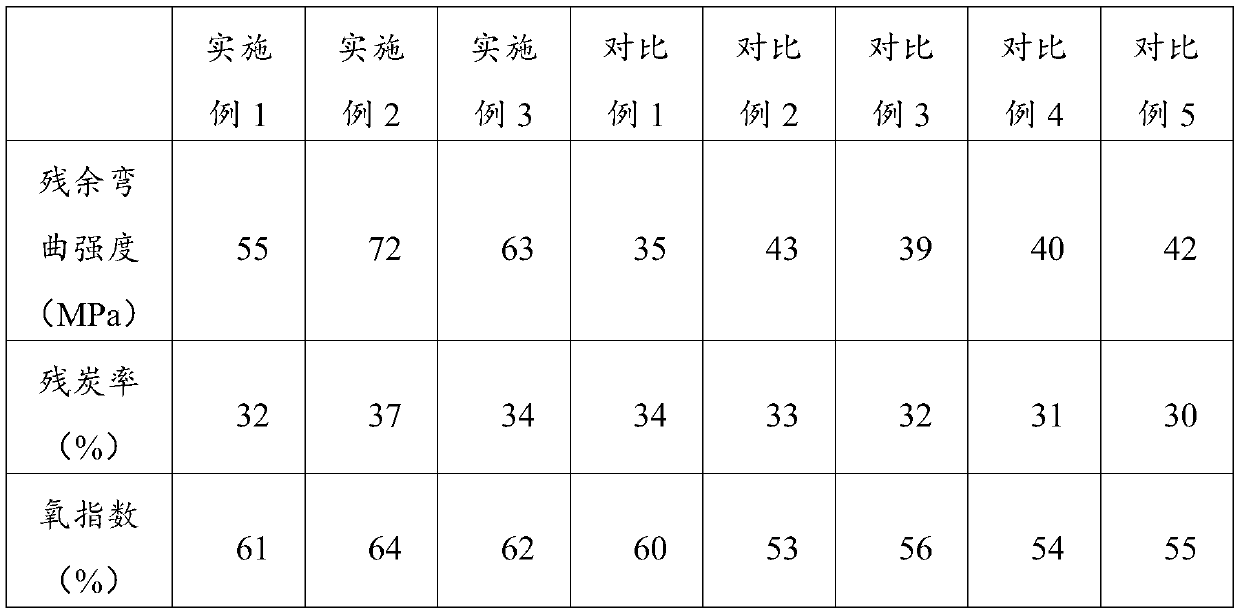

Embodiment 1

[0037] This embodiment provides a high residual strength phenolic flame retardant system FRP material, including the following components:

[0038] 10g of phenolic resin, 10g of epoxy-modified siloxane resin, 1.2g of glass powder, 0.2g of graphite, 0.1g of white carbon black, 0.2g of p-toluenesulfonic acid, 0.2g of urotropine, and 60g of E glass fiber.

[0039] The preparation method is as follows:

[0040] (1) Add 10 g of phenolic resin and 0.2 g of p-toluenesulfonic acid into a beaker, stir well, then add 0.2 g of urotropine and 10 g of epoxy-modified siloxane resin, stir well for later use, and obtain the first mixture.

[0041] (2) 1.2 g of glass powder, 0.2 g of graphite, and 0.1 g of white carbon black were evenly stirred to obtain a second mixture.

[0042] (3) Add the above-mentioned second mixture to the above-mentioned first mixture, and stir evenly to obtain component A.

[0043] (4) Provide 60g of E glass fiber with a length of 11-12cm, lay E glass fiber and comp...

Embodiment 2

[0045] This embodiment provides a high residual strength phenolic flame retardant system FRP material, including the following components:

[0046] 13.1g of phenolic resin, 8.7g of epoxy-modified siloxane resin, 2.2g of glass powder, 0.44g of graphite, 0.11g of white carbon black, 0.22g of p-toluenesulfonic acid, 0.22g of urotropine, and 60g of E glass fiber.

[0047] The preparation method is as follows:

[0048] (1) Add 13.1g of phenolic resin and 0.22g of p-toluenesulfonic acid to the beaker, after stirring well, add 0.22g of urotropine and 8.7g of epoxy-modified siloxane resin successively, stir well for later use, and obtain the first mixture .

[0049] (2) 2.2 g of glass powder, 0.44 g of graphite, and 0.11 g of white carbon black were evenly stirred to obtain a second mixture.

[0050] (3) Add the above-mentioned second mixture to the above-mentioned first mixture, and stir evenly to obtain component A.

[0051] (4) Provide 60g of E glass fiber with a length of 11-12cm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com