Red phosphorus/polyimide covalent organic framework composite material with excellent flame retardant property and preparation method of red phosphorus/polyimide covalent organic framework composite material

A covalent organic framework and polyimide technology, which is applied in the field of preparation of red phosphorus/covalent organic framework composite materials, can solve the problem of high flame retardant performance of red phosphorus/covalent organic framework composite materials. It can solve problems such as public reports of agents, and achieve the effects of better machining performance, simple and easy-to-obtain raw materials, and improved hygroscopicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

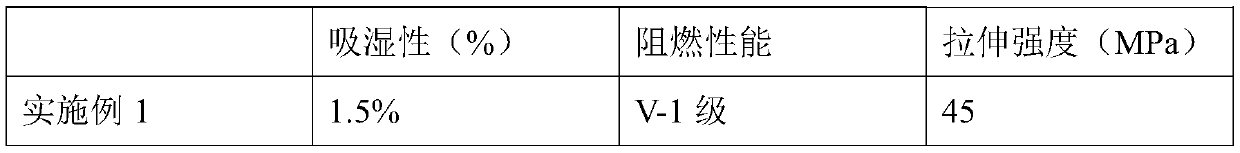

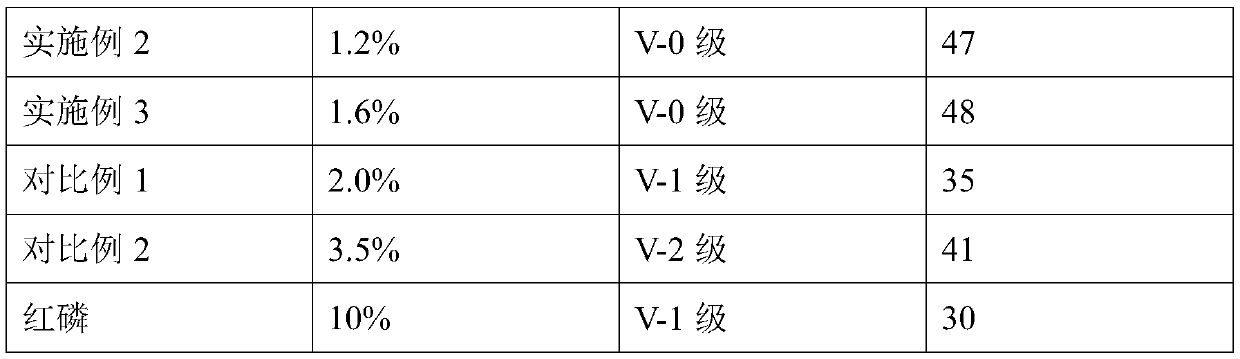

Embodiment 1

[0030] Preparation of Red Phosphorus / Polyimide Covalent Organic Framework Composites

[0031] First, 5g of red phosphorus is added to the concentration of 200mL in the isopropanol dispersion of the polyimide covalent organic framework material of 1g / L, after stirring evenly, the above-mentioned dispersion is placed in a constant temperature ultrasonic water bath for ultrasonication for 5 hours ( The ultrasonic power is 200W), and the temperature is maintained at 40°C during the ultrasonic treatment. Subsequently, the solution after ultrasonic treatment was centrifuged at a rate of 5000r / min, filtered to obtain a dark red powder, and the obtained dark red powder was washed three times with isopropanol, and then dried at 50°C for 10 hours in a blast drying oven. The red phosphorus / polyimide covalent organic framework composite material with a red phosphorus content of 1% by weight can be obtained by naturally cooling to room temperature.

Embodiment 2

[0033] First, 5g red phosphorus is added to the concentration of 200mL in the isopropanol dispersion of the polyimide covalent organic framework material of 5g / L, after stirring evenly, the above-mentioned dispersion is placed in a constant temperature ultrasonic water bath for ultrasonication for 5 hours ( The ultrasonic power is 200W), and the temperature is maintained at 40 degrees during the ultrasonic treatment. Subsequently, the ultrasonically treated solution was centrifuged at a rate of 5000r / min, filtered to obtain a dark red powder, washed three times with isopropanol to the obtained dark red powder, dried in a blast drying oven at 50°C for 10 hours, and cooled naturally The red phosphorus / polyimide covalent organic framework composite material with a red phosphorus weight content of 5% can be obtained at room temperature.

Embodiment 3

[0035] First, 5g of red phosphorus (5nm in size) was added to 200mL of the isopropanol dispersion of polyimide covalent organic framework material (5nm in pore size) with a concentration of 10g / L, and the above-mentioned disperse The solution was placed in a constant temperature ultrasonic water bath for 5 hours (ultrasonic power: 200W), and the temperature was maintained at 40°C during the ultrasonic treatment. Subsequently, the ultrasonically treated solution was centrifuged at a rate of 5000r / min, filtered to obtain a dark red powder, washed three times with isopropanol to the obtained dark red powder, dried in a blast drying oven at 50°C for 10 hours, and cooled naturally The red phosphorus / polyimide covalent organic framework composite material with a red phosphorus content of 10% by weight can be obtained at room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com