Processing method for flame-retardant anti-ultraviolet outer polyester bonded thread

A processing method, the technology of Bondi thread, applied in the direction of flame-retardant fiber, fiber type, improved handle fiber, etc., can solve the problems of non-flame-retardant sewing thread, aging and fading of polyester Bondi thread, ignition and other problems, and achieve rich The effect of special function, simple preparation process and simplified processing flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

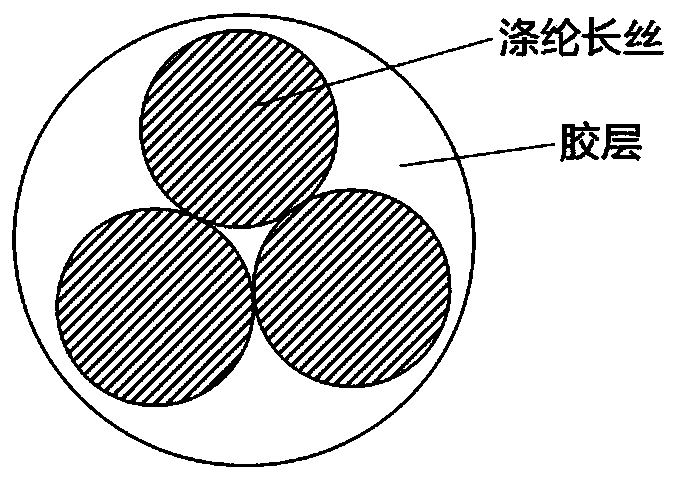

[0022] Such as figure 1 As shown, a processing method of flame-retardant and anti-ultraviolet polyester outer bonded yarn, the polyester filaments are twisted into strands, and then treated with flame-retardant, anti-ultraviolet finishing liquid and resin adhesive in the same bath, at high temperature The surface of the strands is bonded to form a layer of transparent soft film, so as to make a flame-retardant and anti-ultraviolet polyester outer bondy thread. The specific operation steps are as follows:

[0023] (1) Twisting polyester filaments into strands through a twisting machine, the twist direction is S twist or Z twist, and the specifications of the polyester filaments are any of the following: 50D, 70D, 100D, 120D, 150D, 210D , 250D, 420D;

[0024] (2) Configure the dipping finishing solution, and each component is prepared according to the following parts by weight: 19 parts of nitrogen-phosphorus flame retardant, 7 parts of anti-ultraviolet absorber, 24 parts of po...

Embodiment 2

[0028] Such as figure 1 As shown, a processing method of flame-retardant and anti-ultraviolet polyester outer bonded yarn, the polyester filaments are twisted into strands, and then treated with flame-retardant, anti-ultraviolet finishing liquid and resin adhesive in the same bath, at high temperature The surface of the strands is bonded to form a layer of transparent soft film, so as to make a flame-retardant and anti-ultraviolet polyester outer bondy thread. The specific operation steps are as follows:

[0029] (1) Twisting polyester filaments into strands through a twisting machine, the twist direction is S twist or Z twist, and the specifications of the polyester filaments are any of the following: 50D, 70D, 100D, 120D, 150D, 210D , 250D, 420D;

[0030] (2) Configure the dipping finishing solution, and each component is prepared according to the following parts by weight: 27 parts of nitrogen-phosphorus flame retardant, 10 parts of anti-ultraviolet absorber, 32 parts of p...

Embodiment 3

[0034] Such as figure 1 As shown, a processing method of flame-retardant and anti-ultraviolet polyester outer bonded yarn, the polyester filaments are twisted into strands, and then treated with flame-retardant, anti-ultraviolet finishing liquid and resin adhesive in the same bath, at high temperature The surface of the strands is bonded to form a layer of transparent soft film, so as to make a flame-retardant and anti-ultraviolet polyester outer bondy thread. The specific operation steps are as follows:

[0035] (1) Twisting polyester filaments into strands through a twisting machine, the twist direction is S twist or Z twist, and the specifications of the polyester filaments are any of the following: 50D, 70D, 100D, 120D, 150D, 210D , 250D, 420D;

[0036] (2) Configure the dipping finishing solution, and each component is prepared according to the following parts by weight: 23 parts of nitrogen-phosphorus flame retardant, 8 parts of anti-ultraviolet absorber, 29 parts of po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com