Multifunctional magnetic separator

A magnetic separation separation and multi-functional technology, applied in the field of separators, can solve the problems affecting the magnetic separation efficiency, reduced vegetable oil efficiency, poor adsorption effect, etc., and achieves the effects of improving screening efficiency, low cost, and easy cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

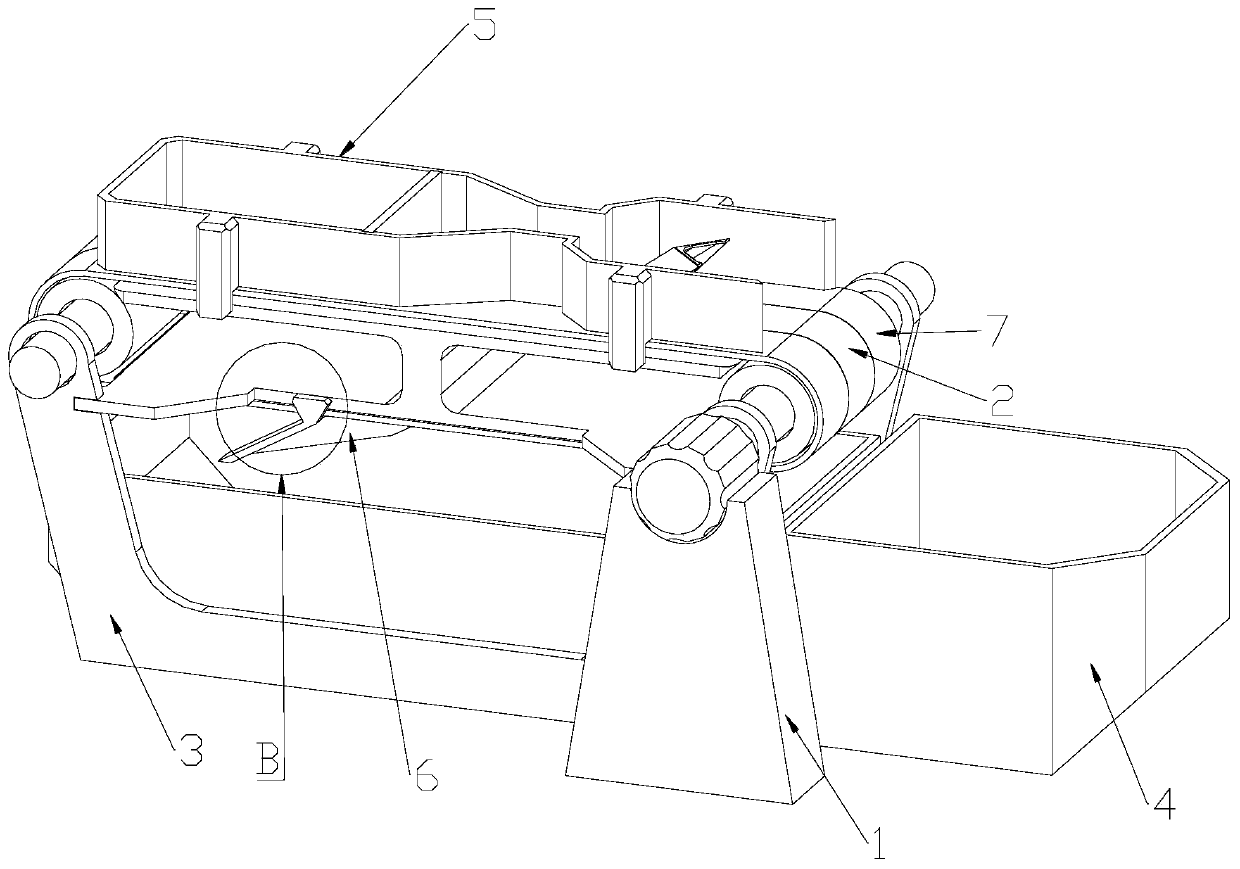

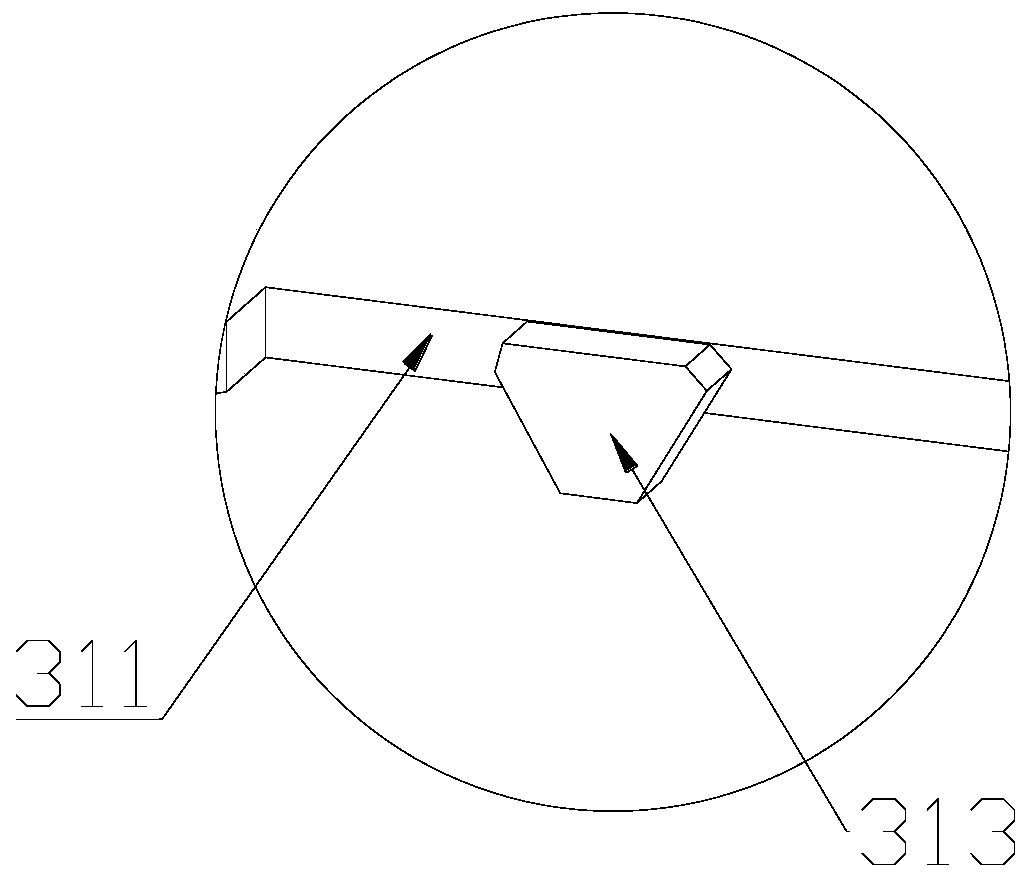

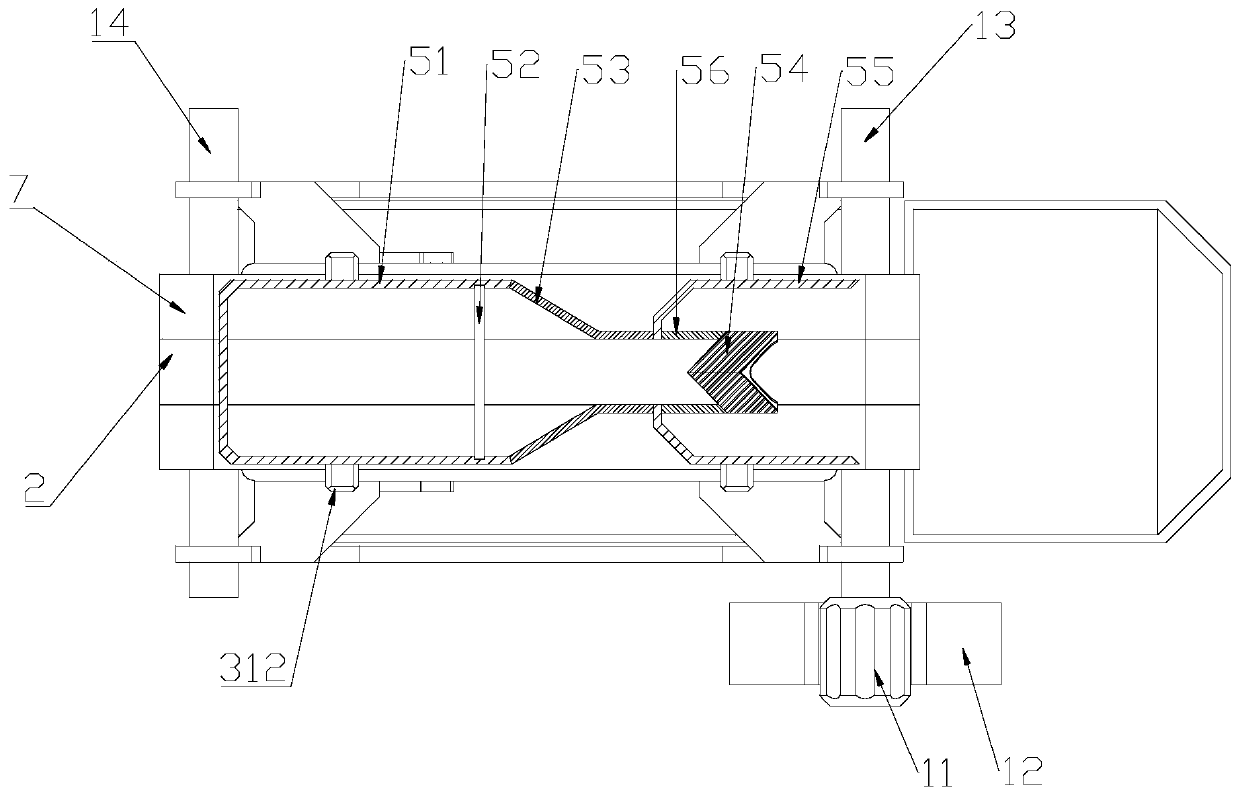

[0040] Such as Figure 1-9 A kind of multi-functional magnetic separation separator shown, comprises conveying device 1, soft magnetic tape 2, support 3, storage device 4, magnetically attracted material stripping plate 6, conveyer belt 7 and the shunt screening device 5 at the uppermost side, conveying device 1 is installed On the bracket 3, the conveyor belt 7 is set on the transmission device 1 and is controlled by the transmission device 1. The outer end of the conveyor belt 7 is provided with an annular groove for installing the soft tape 2, and the soft tape 2 is fixedly set in the annular groove of the conveyor belt 7. , so that the outer surface of the soft magnetic tape 2 is flush with the outer surface of the conveyor belt 7, the storage device 4 is placed under the conveyor 1, and is used to store the separated plant raw materials and magnetic separators respectively, and the shunt screening device 5 and the support 3 It is fixedly connected and is in a non-contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com