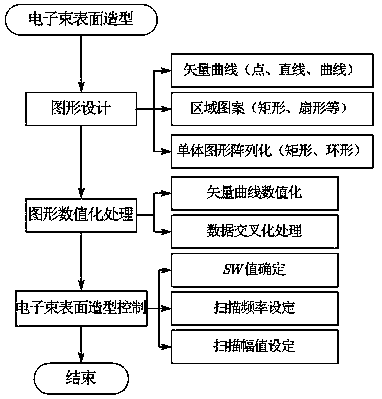

Electron beam surface rapid shaping method based on vectorized control

An electron beam and vectorization technology, applied in electron beam welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of single path style and traditional methods, and achieve the goal of improving flexibility and diversity and improving data editability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The invention provides an aluminum alloy surface modeling method. Specific steps are as follows:

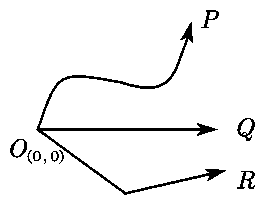

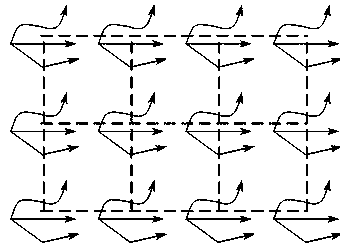

[0042] 1. Design graphics according to the required three-dimensional modeling shape. In this embodiment, it is formed by a C-curve circular array, and one of the C-curve amplitudes (10×5mm) is divided into N 1 =100 data points, carry out numerical calculation through the data points, form a circular array (32 parts), the whole graph has a total of N=3200 points, and the highest frequency at this time is 10 6 / N=3125HZ, and then sort the data in each curve to form a new data group. Finally, the data is imported into the electron beam welding machine control system.

[0043]2. Perform surface mechanical treatment on the surface of the workpiece to be welded, remove oil stains with acetone, alcohol solvent or ultrasonic cleaning, and then place it inside the electron beam welding machine. The distance between the workpiece and the electron gun is about 800mm, and start vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com