Process for reducing iron and generating carbon nanotubes by reforming methane and carbon dioxide

A carbon dioxide, carbon nanotube technology, applied in the direction of carbon nanotubes, nanocarbons, carbon compounds, etc., can solve the problem of not being used to prepare carbon nanotubes, and achieve the effect of ensuring purity, improving efficiency, and rational utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In the first step, a certain mass fraction of crushed iron ore and reduced iron particles are respectively placed in two connected but separated cavities of the rotary furnace, and nitrogen gas is continuously fed into the entire reactor for a certain period of time before the second step .

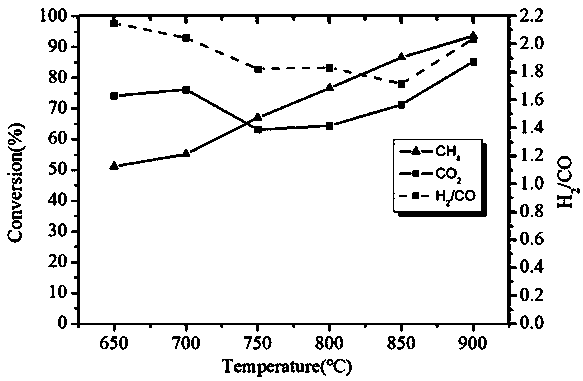

[0027] The second step is to start the heating device at the reduced iron cavity, heat the system where the reduced iron is located to a certain temperature, feed methane and carbon dioxide gas with a certain space velocity and ratio into the cavity, and start the rotary furnace reactor to make it Rotating at a certain speed, the gas stays in the cavity for a certain time.

[0028] The third step is to start the heating device at the iron ore cavity, heat the system where the iron ore is located to a certain temperature, open the valve on the partition, and pass the carbon monoxide and hydrogen gas obtained in the second step reaction into the cavity where the iron ore is located. ...

Embodiment 2

[0038] Same as embodiment 1 step, each parameter is changed into:

[0039] The particle size of iron ore and reduced iron particles described in the first step is 1mm, and the mass fraction of reduced iron is 50 parts;

[0040] In the second step, the final heating temperature is 900°C, the gas ratio of methane and carbon dioxide is 1:0.5, and the gas space velocity is 2000h -1 , the rotating speed of the rotary furnace is 5r / min, and the gas stays in the cavity for 5h;

[0041] In the third step, the final heating temperature is 800°C, the ratio of carbon monoxide to hydrogen is the ratio of gas in the purified tail gas, and the gas space velocity is 3000h -1 , the residence time in the cavity is 5h;

[0042] The proportion of reduced iron refluxed in the fourth step is 25wt%.

Embodiment 3

[0044] Same as embodiment 1 step, each parameter is changed into:

[0045] The particle size of iron ore and reduced iron particles described in the first step is 10mm, and the mass fraction of reduced iron is 100 parts;

[0046] In the second step, the final heating temperature is 1000°C, the ratio of methane to carbon dioxide gas is 1:1, and the gas space velocity is 3000h -1 , the rotating speed of the rotary furnace is 10r / min, and the residence time of the gas in the cavity is 10h;

[0047] In the third step, the final heating temperature is 900°C, the ratio of carbon monoxide to hydrogen is 1:1, and the gas space velocity is 5000h -1 , the residence time in the cavity is 10h;

[0048] The proportion of reduced iron refluxed in the fourth step is 50wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com