Selective synthesis method of 2-chloro-5-methylpyridine and 2, 3-dichloro-5-methylpyridine

A technology of methyl pyridine and a synthetic method, applied in the direction of organic chemistry and the like, can solve the problems of only 56% of the total reaction yield, only 60% of the conversion rate, slow research and development progress, etc., and achieves low production cost, easy operation, and equipment investment. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

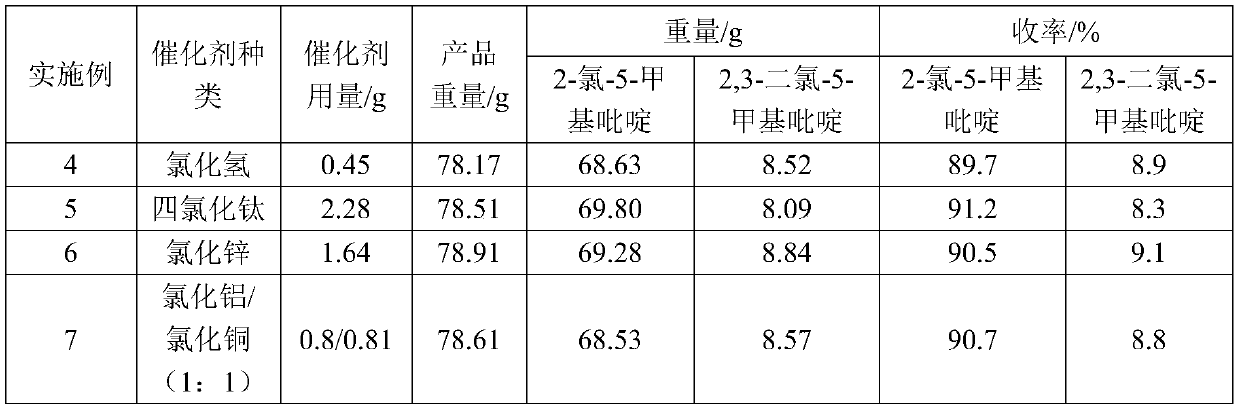

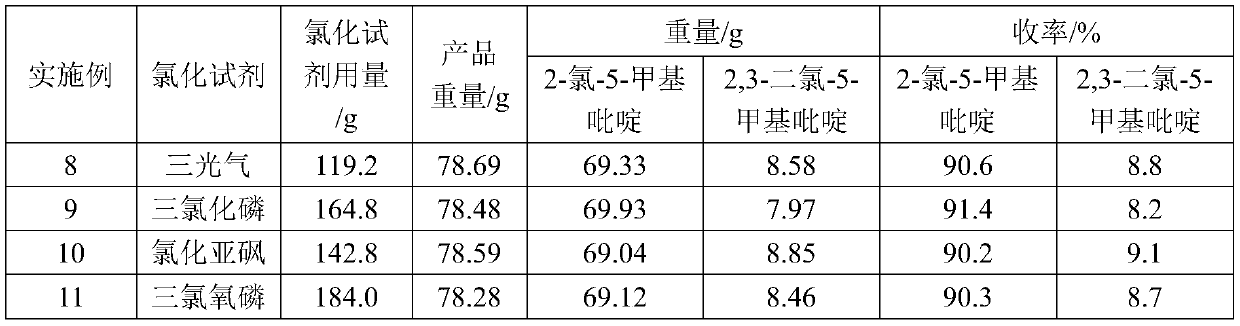

Examples

Embodiment 1

[0019] At 20°C, add 66.7g (0.6mol) of pyridone, 333.5g of toluene, and 2.02g (0.012mol) of ferric chloride into a 500ml four-necked flask, and mix well. Then feed chlorine gas (5.5L / h) in the mixed solution for 3 hours, the reaction is completed, be warming up to 110°C, feed phosgene (9L / h) for 3 hours, react for 1 hour, and obtain product 78.52g through post-processing steps, Among them, 70.11g of 2-chloro-5-methylpyridine and 7.87g of 2,3-dichloro-5-methylpyridine. The yield of 2-chloro-5-methylpyridine to pyridone was 91.6%, and the yield of 2,3-dichloro-5-methylpyridine to pyridone was 8.1%.

Embodiment 2

[0021] At 20°C, add 66.7g (0.6mol) of pyridone, 333.5g of toluene, 9.8g (0.06mol) of ferric chloride into a 500ml four-necked flask, and feed phosgene (9L / h) for 3 hours; then Chlorine gas (9.5L / h) was passed into the mixed solution simultaneously for 3h, the reaction was completed, the temperature was raised to 110°C, phosgene (9L / h) was passed through again for 3 hours, and the reaction was carried out for 1 hour, and 93.95g of the product was obtained through the post-processing step. Among them, 14.16g of 2-chloro-5-methylpyridine and 79.03g of 2,3-dichloro-5-methylpyridine. The yield of 2-chloro-5-methylpyridine to pyridone was 18.5%, and the yield of 2,3-dichloro-5-methylpyridine to pyridone was 81.3%.

Embodiment 3

[0023] Change ferric trichloride, phosgene and chlorine consumption on the basis of embodiment 2, add ferric trichloride 4.87g (0.03mol), pass into phosgene (4.5L / h) 3 hours, pass into chlorine gas (7.5L / h) for 3 hours. After the reaction, 88.43 g of the product was obtained through post-processing steps, including 33.07 g of 2-chloro-5-picoline and 54.92 g of 2,3-dichloro-5-picoline. The yield of 2-chloro-5-methylpyridine to pyridone was 43.2%, and the yield of 2,3-dichloro-5-methylpyridine to pyridone was 56.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com