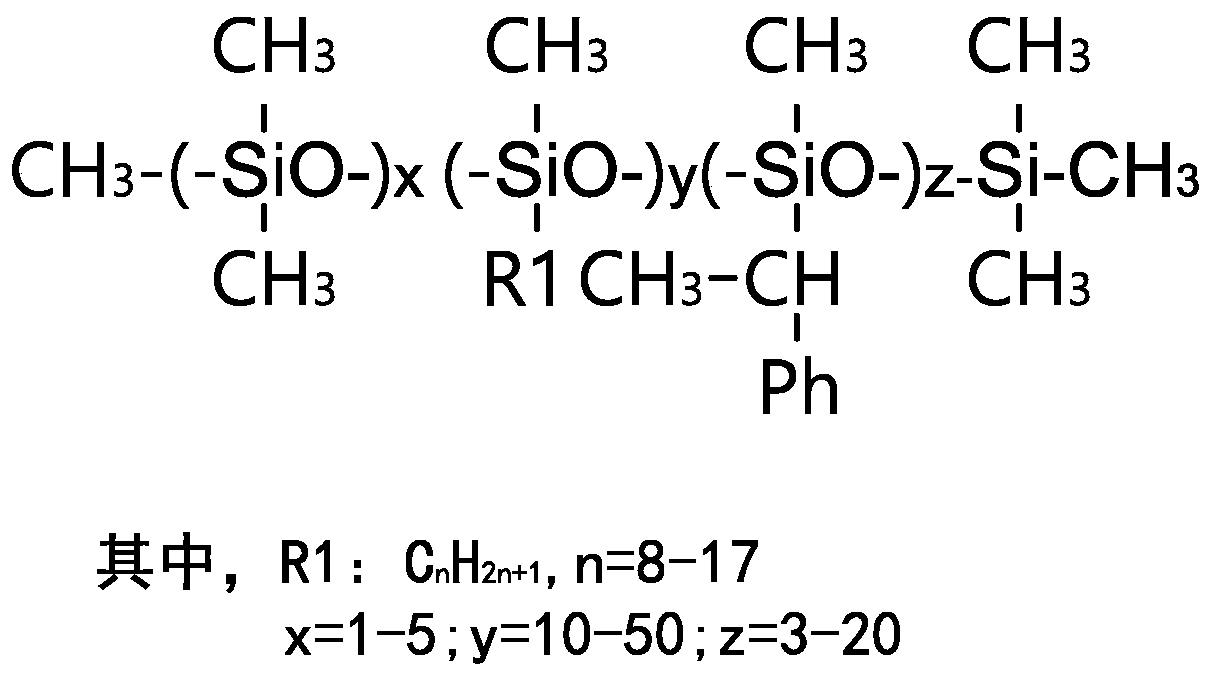

Preparation method of long-chain alkyl phenyl modified silicone oil

A technology of long-chain alkylphenyl and modified silicon, which is applied in the field of organic silicon, which can solve the problems of incomplete catalyst reaction and dark product color, and achieve the effect of improving dispersion and fully uniform reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

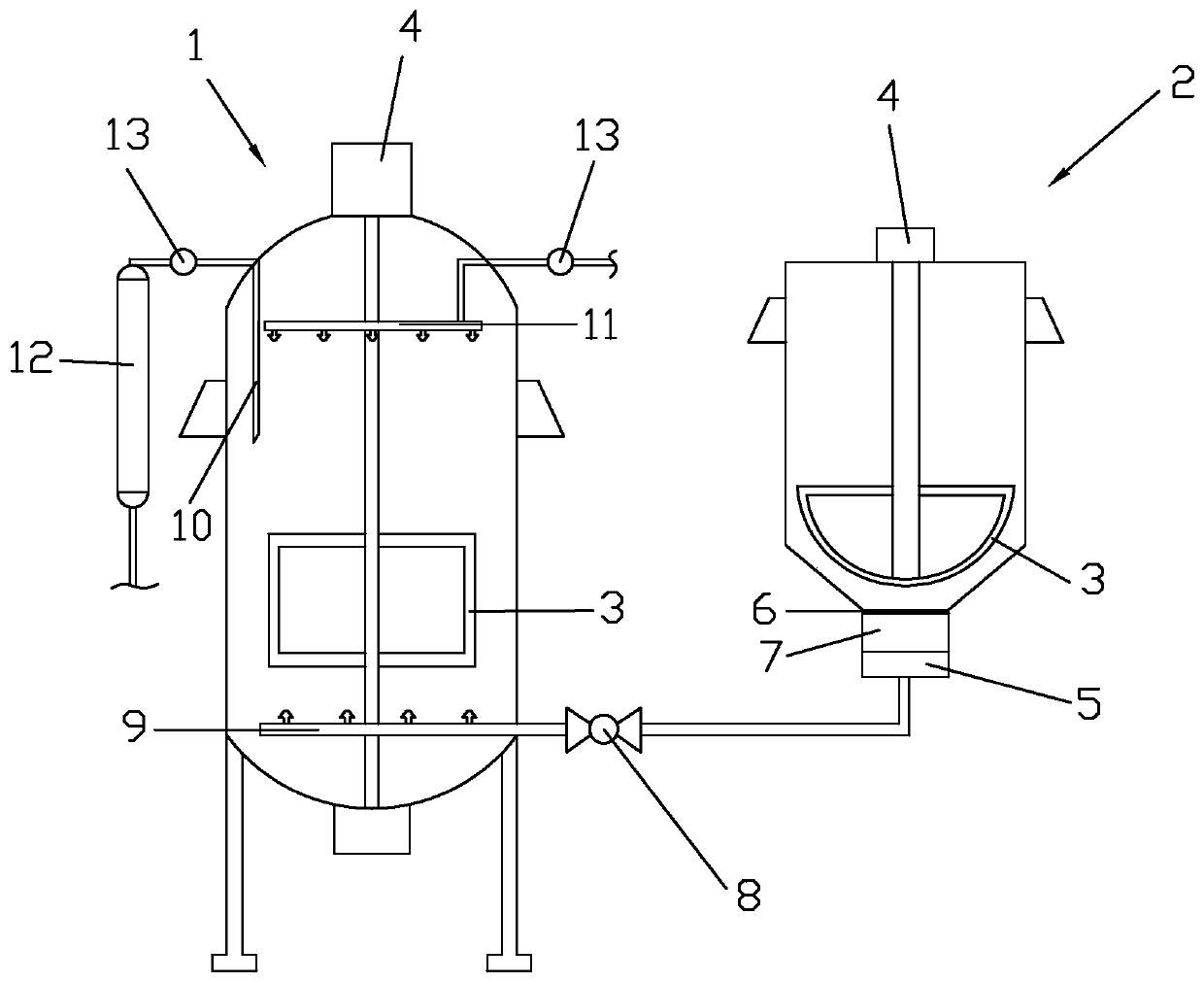

Method used

Image

Examples

Embodiment 1

[0040] To prepare Karstedt's catalyst:

[0041] (1) Add chloroplatinic acid and isopropanol into the stirring tank, and stir at room temperature for 0.5h;

[0042] (2) Add sodium bicarbonate, heat up to 50°C, and stir for 0.5h;

[0043] (3) Add 1,3-divinyltetramethyldisiloxane and stir for 1 h;

[0044] (4) The stirred tank was kept warm at 50°C for 1 hour of precipitation.

[0045] Wherein, the mass ratio of chloroplatinic acid:isopropanol:sodium bicarbonate:1,3-divinyltetramethyldisiloxane is 1:50:25:25.

[0046] Preparation of long-chain alkylphenyl modified silicone oil:

[0047] (1) Part of the Karstedt catalyst is added to the reactor;

[0048] (2) Pass α-methylstyrene into the filter column containing neutral alumina under the protection of inert gas and then flow into the reactor, heat up to 70°C, stir for 0.5h, and the stirring speed is 100n / min;

[0049] (3) Drop hydrogen-containing silicone oil with a hydrogen content of 0.5wt% into the reactor for 0.5 hours, s...

Embodiment 2

[0055] To prepare Karstedt's catalyst:

[0056] (1) Add chloroplatinic acid and isopropanol into the stirring tank, and stir at room temperature for 1 hour;

[0057] (2) Add sodium bicarbonate, heat up to 75°C, and stir for 1h;

[0058] (3) Add 1,3-divinyltetramethyldisiloxane and stir for 1 h;

[0059] (4) The stirred tank was kept warm at 70°C for 1 hour of precipitation.

[0060] Wherein, the mass ratio of chloroplatinic acid:isopropanol:sodium bicarbonate:1,3-divinyltetramethyldisiloxane is 1:100:30:30.

[0061] Preparation of long-chain alkylphenyl modified silicone oil:

[0062] (1) Part of the Karstedt catalyst is added to the reactor;

[0063] (2) Pass α-methylstyrene through a filter column containing neutral alumina under the protection of an inert gas, then flow into the reactor, heat up to 85°C, stir for 1 hour, and the stirring speed is 100n / min;

[0064] (3) Drop hydrogen-containing silicone oil with a hydrogen content of 1 wt% into the reaction kettle for 1 h...

Embodiment 3

[0070] Karstedt's catalyst was formulated as in Example 2.

[0071] Preparation of long-chain alkylphenyl modified silicone oil:

[0072] (1) Part of the Karstedt catalyst is added to the reactor;

[0073] (2) Pass α-methylstyrene through a filter column containing neutral alumina under the protection of an inert gas, then flow into the reactor, heat up to 80°C, stir for 1 hour, and the stirring speed is 100n / min;

[0074] (3) Drop hydrogen-containing silicone oil with a hydrogen content of 1 wt% into the reaction kettle for 1 hour, stir for 2 hours while the reaction temperature rises to 110°C to obtain phenyl-modified silicone oil;

[0075] (4) add the remaining Karstedt catalyst in the stirred tank in the reactor;

[0076] (5) Pass α-dodecene through a filter column containing neutral alumina under the protection of an inert gas and then flow into the reactor, stir for 2 hours and keep the temperature at 140°C with a stirring speed of 100n / min to obtain a long Alkylpheny...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com