High-life gray iron for forming metal casting mould and preparation method of high-life gray iron

A mold forming and metal molding technology, which is applied in the field of high-life gray iron for metal casting mold molding and its preparation, can solve the problems of reducing the manufacturing cost and construction period of metal molds, and achieve the effect of high thermal conductivity and slow growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

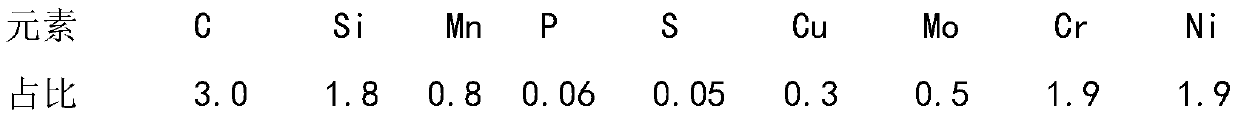

[0037] Use the gray iron material of this application to make the motor shell mold, and the alloy and proportion are as follows:

[0038]

[0039] The mechanical properties are as follows:

[0040] Hardness≥HB180.

[0041] Tensile strength ≥ 240MPa.

[0042] The mold life reaches 40,000 mold times.

[0043] The deformation ratio is less than 0.00001.

Embodiment 2

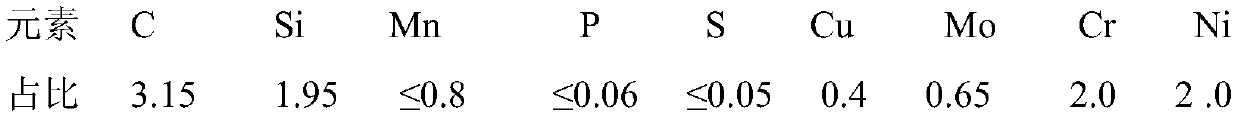

[0045] Using this application to produce engine cylinder head molds, the alloys and proportions are as follows:

[0046]

[0047] The mechanical properties are as follows:

[0048] The mold life reaches 51,000 mold times.

[0049] The deformation ratio is less than 0.00001.

[0050] Hardness: Hardness ≥HB190.

[0051] Strength: Tensile strength ≥ 250MPa.

Embodiment 3

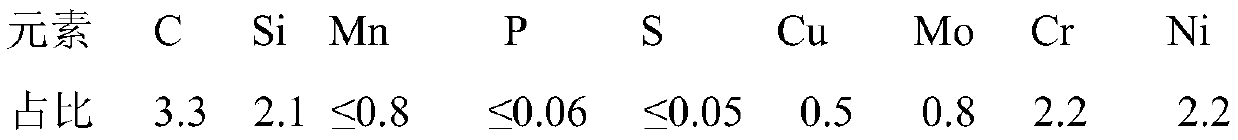

[0053] The alloy and proportion of the new energy vehicle sub-frame mold using the material of the present invention are as follows:

[0054]

[0055] The surface roughness reaches 3.2;

[0056] The demoulding force is lower than that of die steel;

[0057] The mechanical properties are as follows:

[0058] Hardness: Hardness≥HB200.

[0059] Tensile strength ≥ 270MPa.

[0060] The life of the mold reaches 57,000 mold times.

[0061] The deformation amount ratio is less than 0.00001.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com