Preparation process of antibacterial polyester fiber fabric

A polyester fiber and preparation technology, applied in the field of clothing fabrics, can solve the problems of threatening the wearer's health and safety, lack of antibacterial properties, etc., and achieve the effects of blood oxygen delivery, human health, and sleep improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

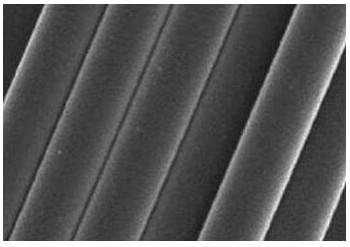

Image

Examples

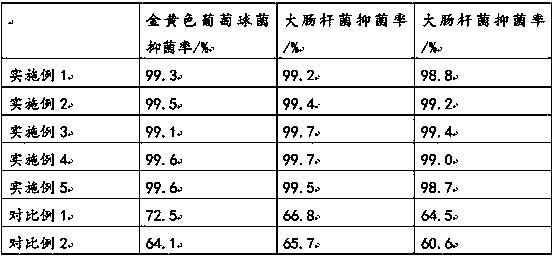

Embodiment 1

[0055]A preparation process for antibacterial polyester fiber fabrics. Tourmaline is ground in the presence of polyethylene glycol to obtain tourmaline powder. The mixing ratio of tourmaline and polyethylene glycol is 150g: 400mL, and the grinding time is 5 hours. The grinding speed is 1800r / min, the average particle size of tourmaline powder is 30μm; the particle size of titanium dioxide is 1μm. The mass ratio of tourmaline powder and titanium dioxide is 1:1; the tourmaline powder and titanium dioxide are mixed and then added to the maleic anhydride solution for grafting reaction to obtain grafted tourmaline mixed powder. The grafting reaction is: mixing tourmaline powder and titanium dioxide Then add it to maleic anhydride solution, heat to 60°C, stir at 500r / min for 30min, then keep it warm for 1 hour, then carry out suction filtration, wash the surface to neutral, dry to constant weight, and obtain; Described tourmaline powder and maleic anhydride solution mixing ratio are...

Embodiment 2

[0061] A preparation process for antibacterial polyester fiber fabrics. Tourmaline is ground in the presence of polyethylene glycol to obtain tourmaline powder. The mixing ratio of tourmaline and polyethylene glycol is 150g: 500mL, and the grinding time is 5 hours. The grinding speed is 1800r / min, the average particle size of tourmaline powder is 30μm; the particle size of titanium dioxide is 1μm. The mass ratio of tourmaline powder and titanium dioxide is 1:2; the tourmaline powder and titanium dioxide are mixed and then added to the maleic anhydride solution for grafting reaction to obtain grafted tourmaline mixed powder. The grafting reaction is: mixing tourmaline powder and titanium dioxide Then add it to the maleic anhydride solution, heat to 66°C, stir at 500r / min for 30min, then keep it warm for 1 hour, then carry out suction filtration, wash the surface to neutral, dry to constant weight, and obtain; The mixing ratio of the tourmaline powder and the maleic anhydride so...

Embodiment 3

[0067] A preparation process for antibacterial polyester fiber fabrics. Tourmaline is ground in the presence of polyethylene glycol to obtain tourmaline powder. The mixing ratio of tourmaline and polyethylene glycol is 150g: 450mL, and the grinding time is 5 hours. The grinding speed is 1800r / min, the average particle size of tourmaline powder is 30μm; the particle size of titanium dioxide is 1μm. The mass ratio of tourmaline powder to titanium dioxide is 1:1.2; the tourmaline powder and titanium dioxide are mixed and then added to the maleic anhydride solution for grafting reaction to obtain grafted tourmaline mixed powder. The grafting reaction is: mixing tourmaline powder with titanium dioxide Then add it to the maleic anhydride solution, heat to 63°C, stir at 500r / min for 30min, then keep it warm for 1 hour, then carry out suction filtration, wash the surface to neutral, dry to constant weight, and obtain; Described tourmaline powder and maleic anhydride solution mixing ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com