Engine controller testing device with aerogel box and testing method

An engine controller and testing device technology, applied in electrical testing/monitoring, general control systems, control/regulating systems, etc., can solve the problems affecting the accuracy of the engine controller, inaccurate temperature constants, and low reliability. Avoid heat waste, reduce test costs, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

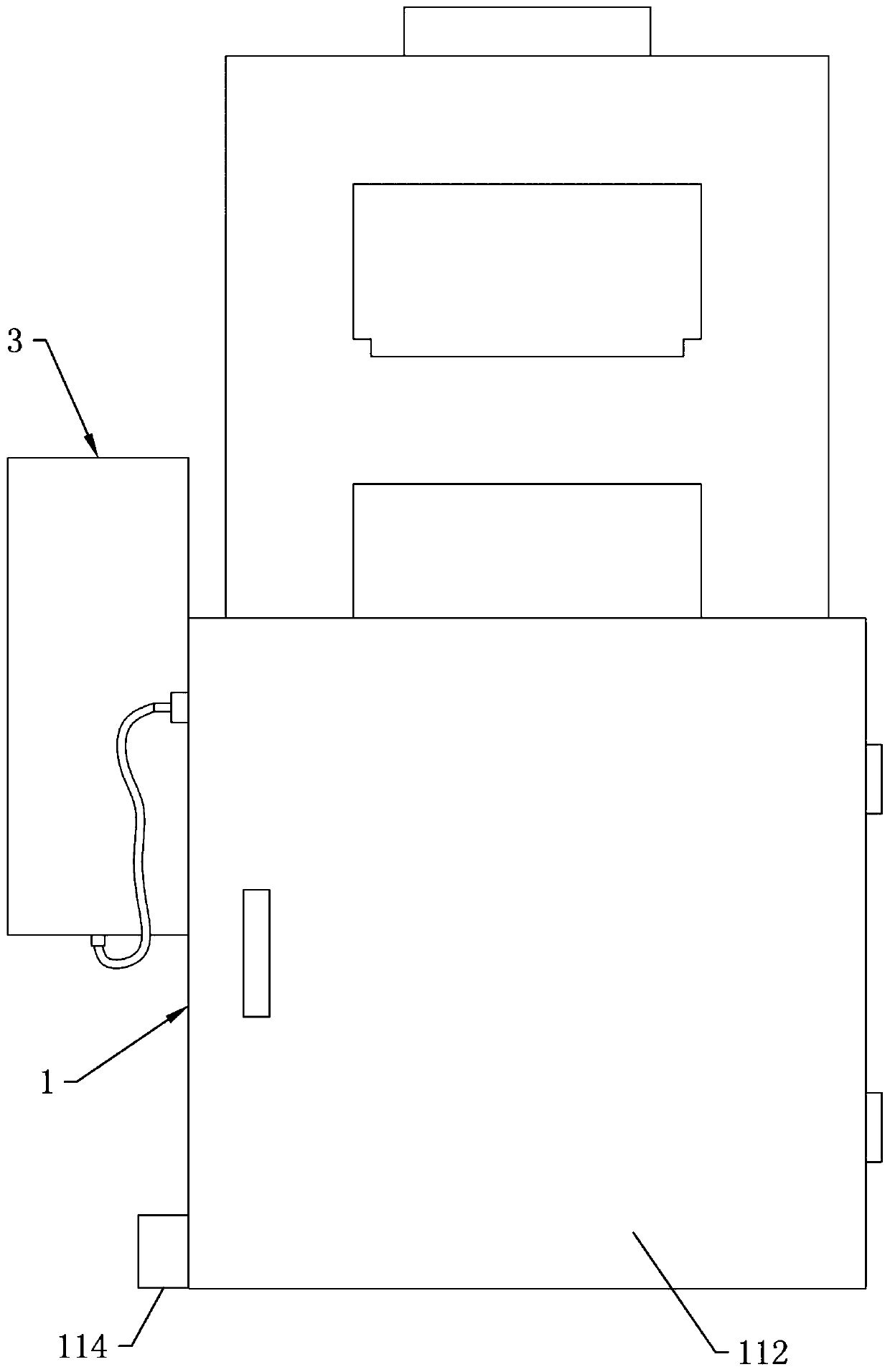

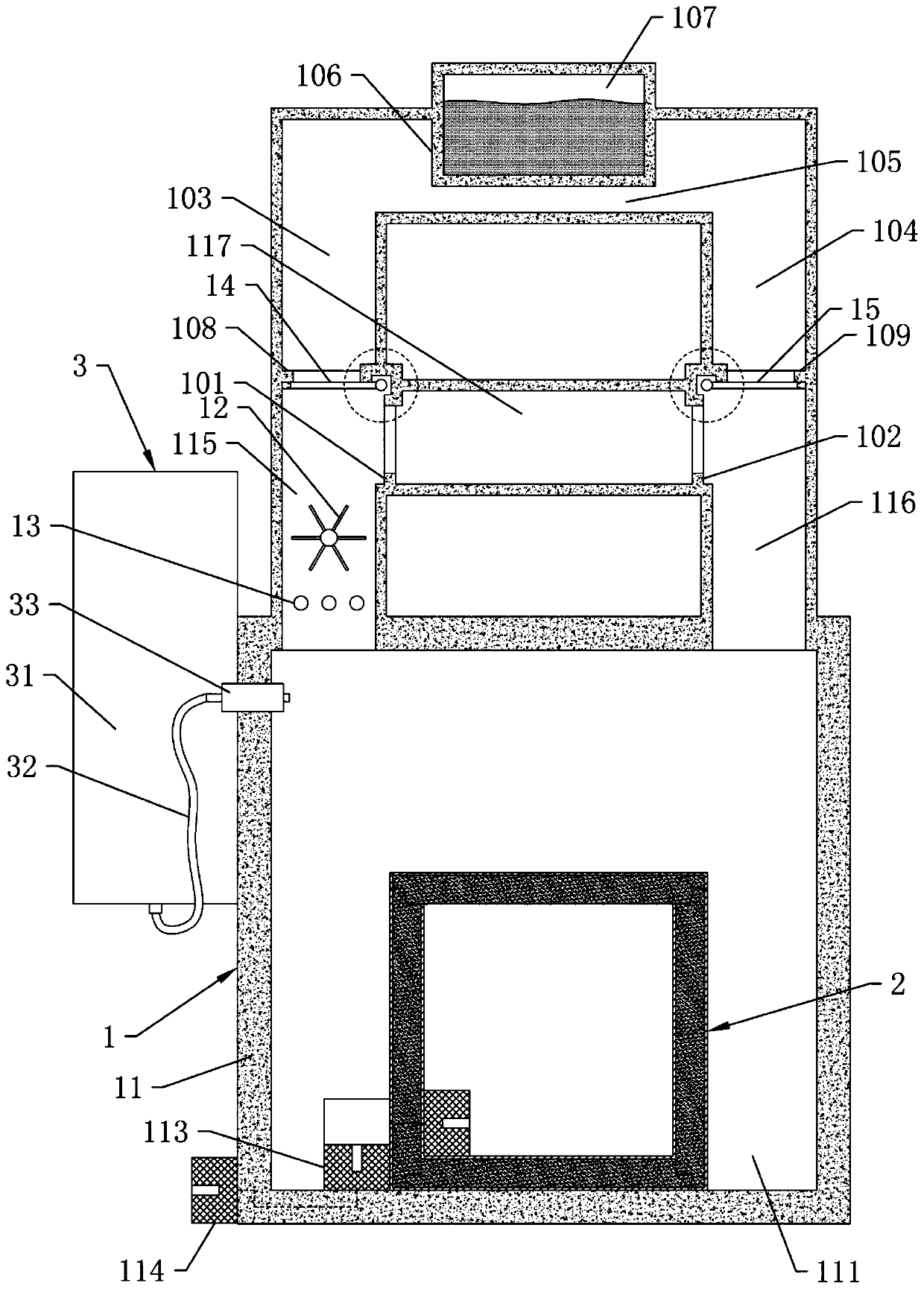

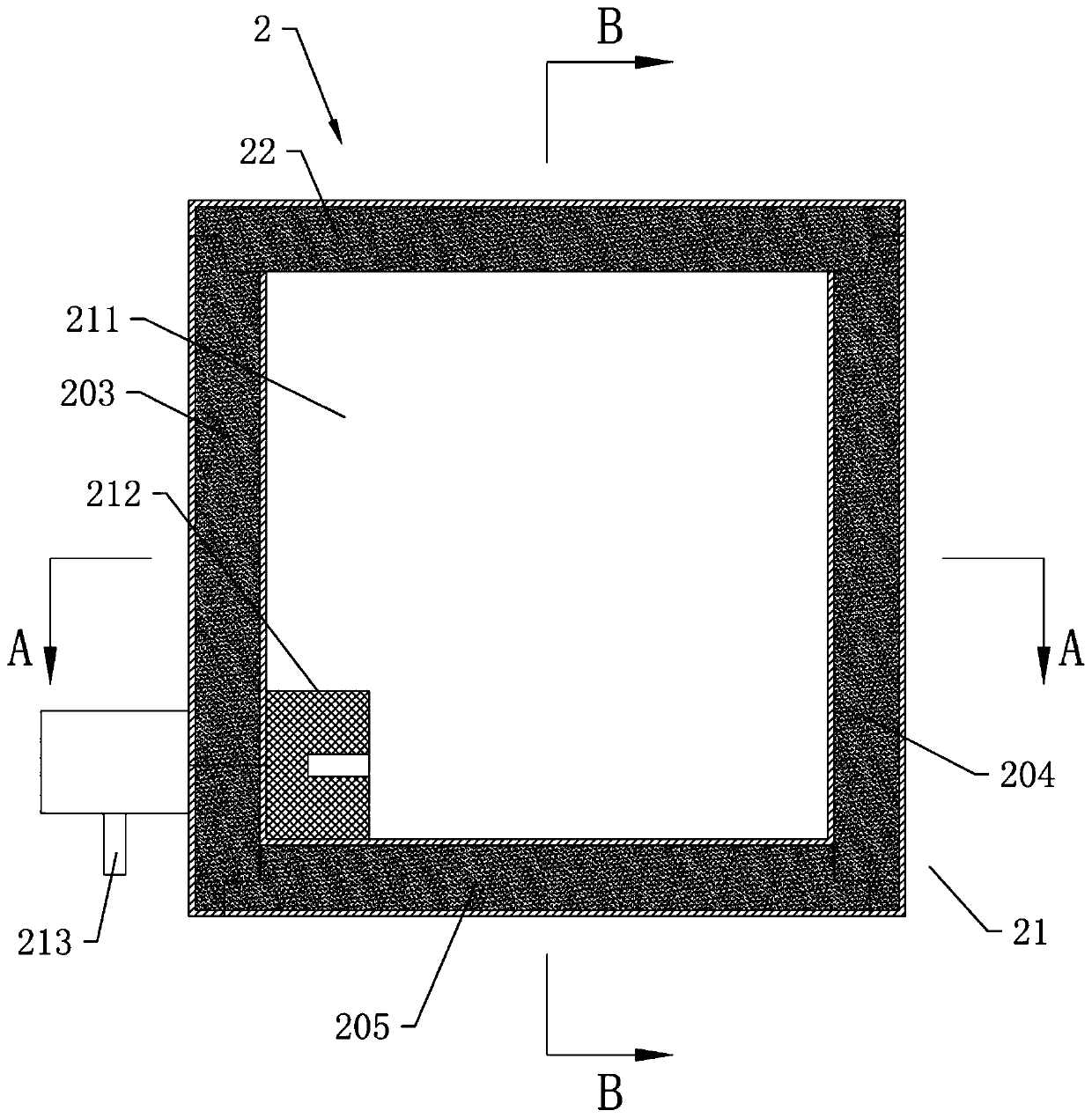

[0031] Such as figure 1 and figure 2 As shown, a kind of engine controller testing device with airgel box according to the present invention comprises heating box body 1, airgel box body 2, fire extinguishing assembly 3, wherein, as figure 1 , figure 2 , Image 6 and Figure 7 As shown, the heating box 1 includes a box body 11, a fan 12, a heating wire 13, a left sealing assembly 14, and a right sealing assembly 15. The front of the box body 11 is provided with an accommodating cavity 111, and the accommodating cavity 111 A cover door 112 is provided on the mouth of the chamber, a first connection socket 113 is provided on the lower chamber wall of the accommodating chamber 111, a second connection socket 114 is provided on the side wall of the box body 11, and the second connection socket 114 is electrically connected with the first connection socket 113, and the upper cavity wall of the accommodation cavity 111 is respectively provided with a vertically extending air o...

Embodiment 2

[0045] A method for testing an engine controller, comprising the engine controller testing device described in Embodiment 1, and also including an engine controller and a tester, comprising the following steps:

[0046] The first step is to arrange the engine controller in the placement cavity 211, and insert the engine controller into the detection socket 212; place the heat insulation box 21 in the accommodation cavity 111, and insert the detection plug 213 into the first connection On the socket 113, the case cover 22 is also opened, and then the cover door 112 is closed; the tester is inserted on the second connecting socket 114;

[0047]The second step is to turn on the heating wire 13 and the blower fan 12, so that the temperature of the accommodation chamber 111 rises to A degree Celsius, the said A is greater than or equal to 40, and then keep warm for B hours, and after the temperature of the placement chamber 211 also reaches A degree Celsius, close the box cover 22;...

Embodiment 3

[0058] A method for testing an engine controller, comprising the engine controller testing device described in Embodiment 1, and also including an engine controller and a tester, comprising the following steps:

[0059] The first step is to arrange the engine controller in the placement cavity 211, and insert the engine controller into the detection socket 212; place the heat insulation box 21 in the accommodation cavity 111, and insert the detection plug 213 into the first connection On the socket 113, the case cover 22 is also opened, and then the cover door 112 is closed; the tester is inserted on the second connecting socket 114;

[0060] In the second step, the temperature of the housing cavity 111 is raised to the critical temperature H degree Celsius that the engine controller can bear through the heating wire 13 and the blower fan 12, and kept for 24 hours, until the temperature in the heat insulation box 21 reaches H degrees Celsius, close the heat insulation box twen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com