A lithium ion battery pole piece, its preparation method and lithium ion battery

A lithium-ion battery and pole piece technology, applied in battery electrodes, electrode manufacturing, electrode collector coating, etc., can solve the problem that the gel state electrolyte cannot infiltrate the pole piece, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] Example 1 Preparation of positive electrode plate ① of lithium ion battery

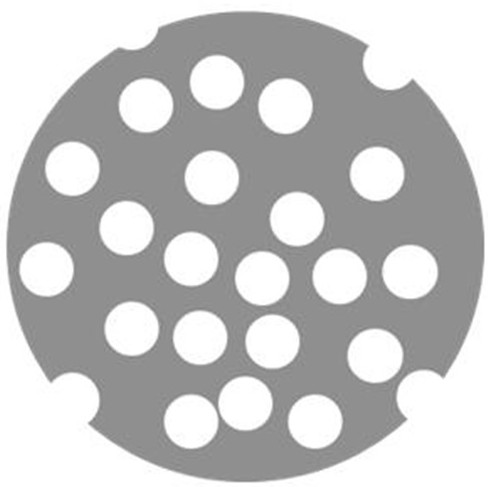

[0088] The porous material involved in this embodiment is a microporous ceramic; the electrode material is a positive electrode material. The positive electrode material is lithium cobalt oxide. The gel electrolyte is a gel electrolyte for lithium ion batteries.

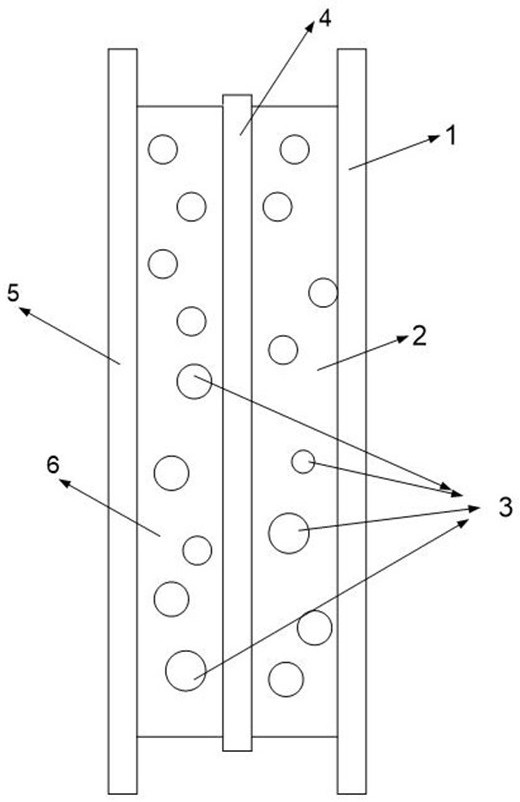

[0089] 1) prepare the mixed membrane material for the upper and lower layers of the storage electrolyte layer;

[0090] 2) coating the surface of the current collector with the mixed film material for the lower layer prepared in step 1), heat treating the lower layer, cooling down and cooling;

[0091] 3) Cool and cool the mixed film material for the upper layer prepared in step 1), coat the surface of the lower layer of the pole piece obtained in step 2), stand and dry.

[0092] Step 1) The preparation of the mixed membrane material for the lower layer of the electrolyte layer includes: a porous material, an electrode material, a ...

Embodiment 2

[0109] Example 2 Preparation of negative pole piece ① of lithium ion battery

[0110] The steps and parameters not mentioned in this embodiment are the same as those in Embodiment 1. The porous material involved is a microporous ceramic; the electrode material is a negative electrode material. The negative electrode material is carbon nanotubes. The gel electrolyte is the same as in Example 1.

[0111] 1) prepare the mixed membrane material for the upper layer and the lower layer of the storage electrolyte layer;

[0112] 2) coating the surface of the current collector with the mixed film material for the lower layer prepared in step 1), heat treating the lower layer, cooling down and cooling;

[0113] 3) Cool and cool the mixed film material for the upper layer prepared in step 1), coat the surface of the lower layer of the pole piece obtained by the treatment in step 2), stand and dry.

[0114]Step 1) The preparation of the mixed membrane material for the lower layer of ...

Embodiment 3

[0131] Example 3 Preparation of positive electrode plate ② of lithium ion battery

[0132] The porous material involved in this embodiment is macroporous alumina; the electrode material is a positive electrode material. The positive electrode material is lithium iron phosphate. The gel electrolyte is a gel electrolyte for lithium ion batteries.

[0133] 1) prepare the mixed membrane material for the upper and lower layers of the storage electrolyte layer;

[0134] 2) coating the surface of the current collector with the mixed film material for the lower layer prepared in step 1), heat treating the lower layer, cooling down and cooling;

[0135] 3) Cool and cool the mixed film material for the upper layer prepared in step 1), coat the surface of the lower layer of the pole piece obtained in step 2), stand and dry.

[0136] Step 1) The preparation of the mixed membrane material for the lower layer of the electrolyte layer includes: a porous material, an electrode material, a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com