Method, casting mold and device for producing a vehicle wheel

A technology for casting molds and wheels, which is applied in the field of wheel manufacturing devices, can solve the problems of high requirements for casting driving energy, time-consuming and cost-consuming casting molds, and deterioration of casting results, so as to improve aerodynamics, increase weight, and avoid related deformations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

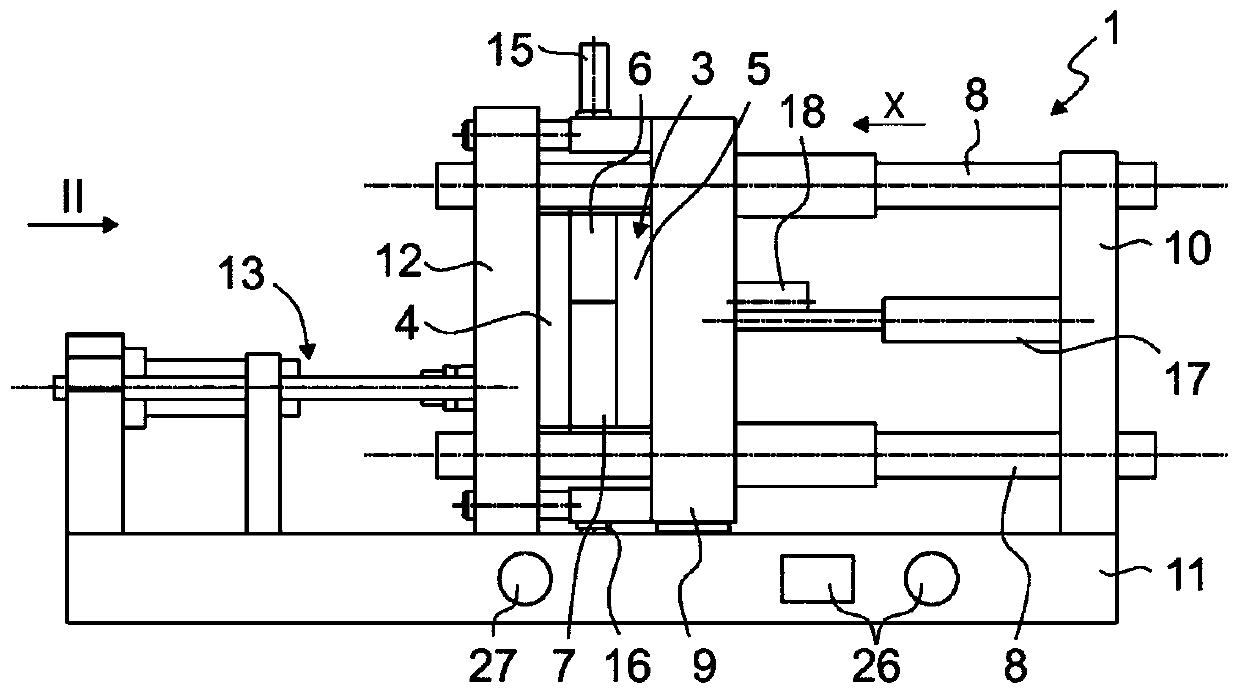

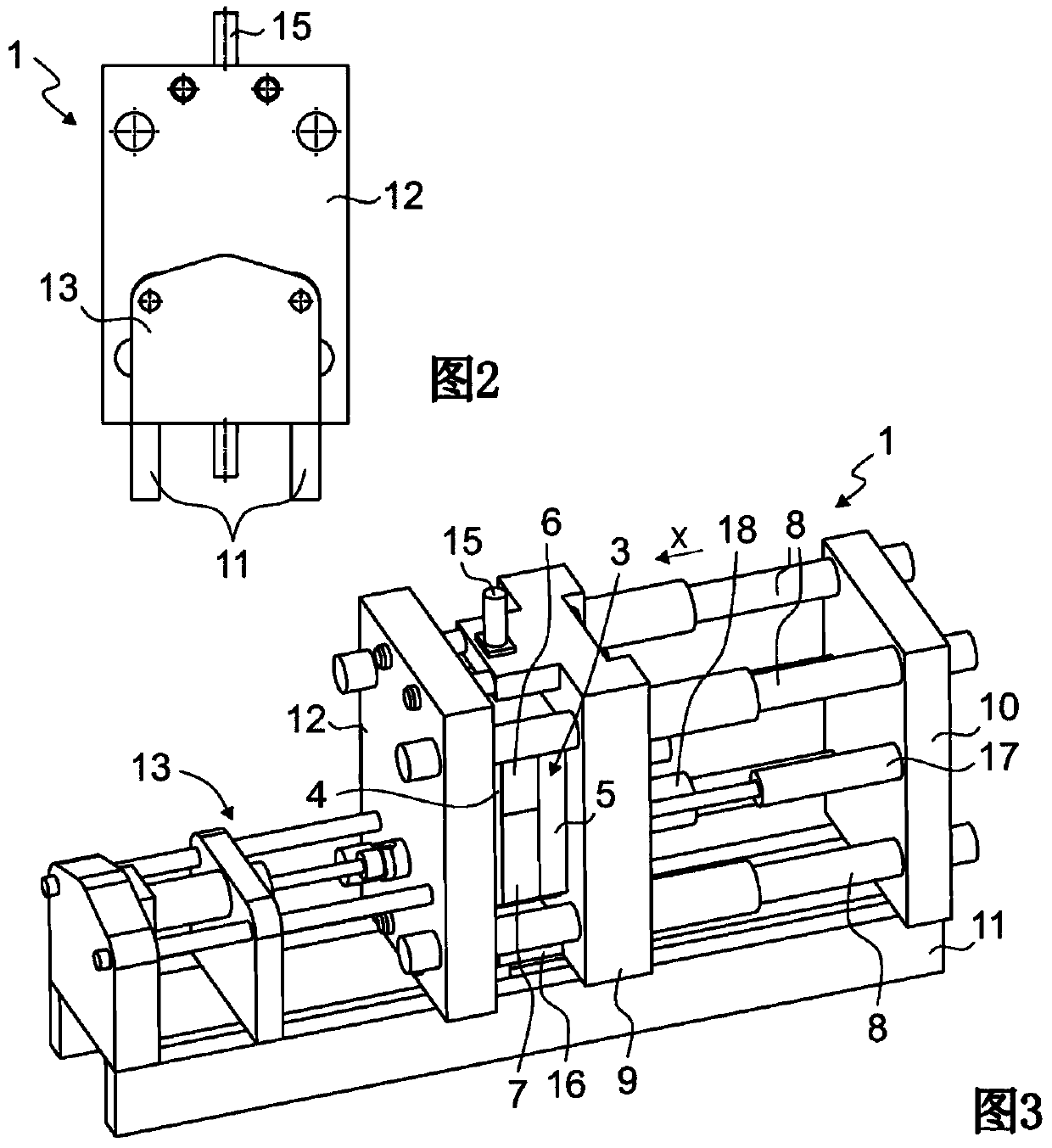

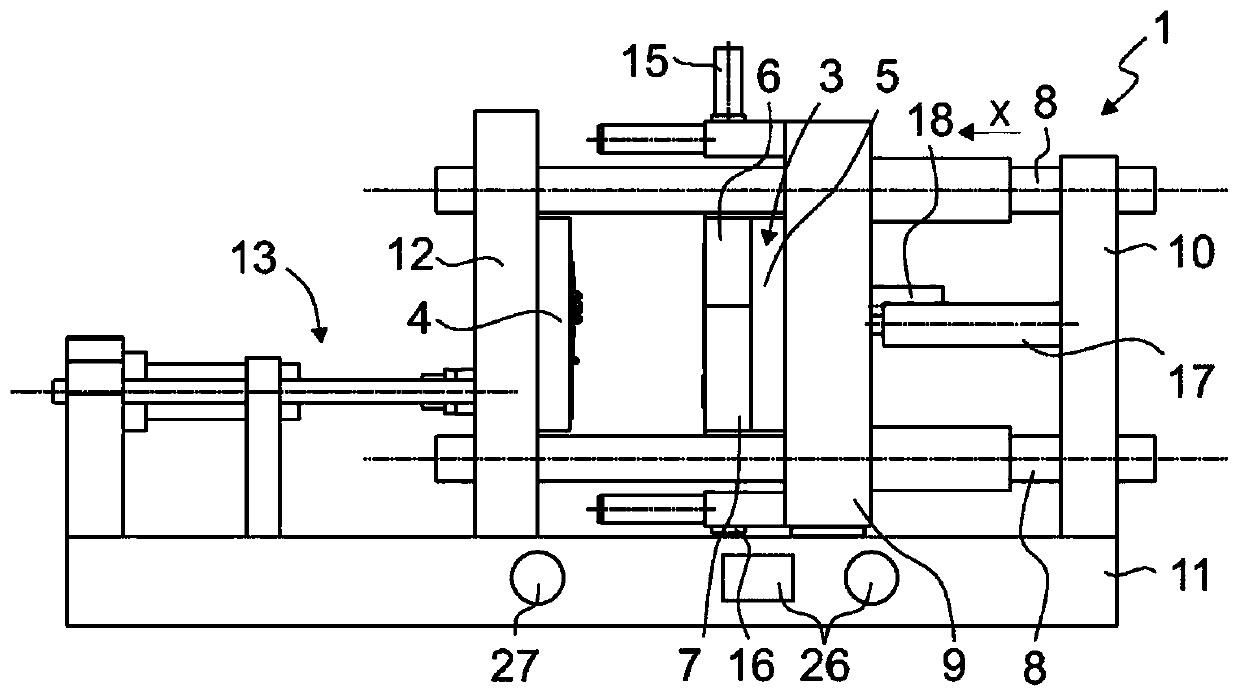

[0064] Figures 1 to 9 shown Figures 6 to 9 Different views of a plant 1 for producing wheels 2 by die casting are shown. The wheel 2 can be of basically any size and shape. therefore, Figures 6 to 9 The wheel 2 shown should be regarded as a pure example. A light metal material, preferably aluminum or magnesium, is used for the pressure casting of the wheel 2 . For this purpose, light metal materials known per se and suitable for the method described below can be used to manufacture the wheel 2 .

[0065] The device 1 has a casting mold 3 such as figure 1 , 2 The casting mold 3 shown in and 3 is in a closed position. In this example, the casting mold 3 has four molded parts, namely a rigid or immovable mold half 4 , a movable mold half 5 , a sprue or slide 6 and a sprue or slide 7 . The molded part of the casting mold 3 may or may not accommodate the zero point system, and the molded part may have a very smooth and high quality surface which does not need to be treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com