A pharmaceutical composition for administering benzodiazepines through nasal mucosa, its preparation method and application

A benzodiazepine and composition technology, applied in the field of pharmaceutical preparations, can solve the problems of high industrialized production cost, inconvenient medication for patients, large amount of auxiliary materials, etc., and achieve the effects of prolonging action time, enhancing self-immunity, and ensuring drug efficacy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Compound (R) shown in embodiment 1 formula (I) 1 is methyl, R 2 Prepared for nasal mucosal administration of methyl) benzenesulfonate

[0070] The liposome prescription is as shown in the table,

[0071]

[0072] Preparation Process:

[0073] 1. Microparticle preparation:

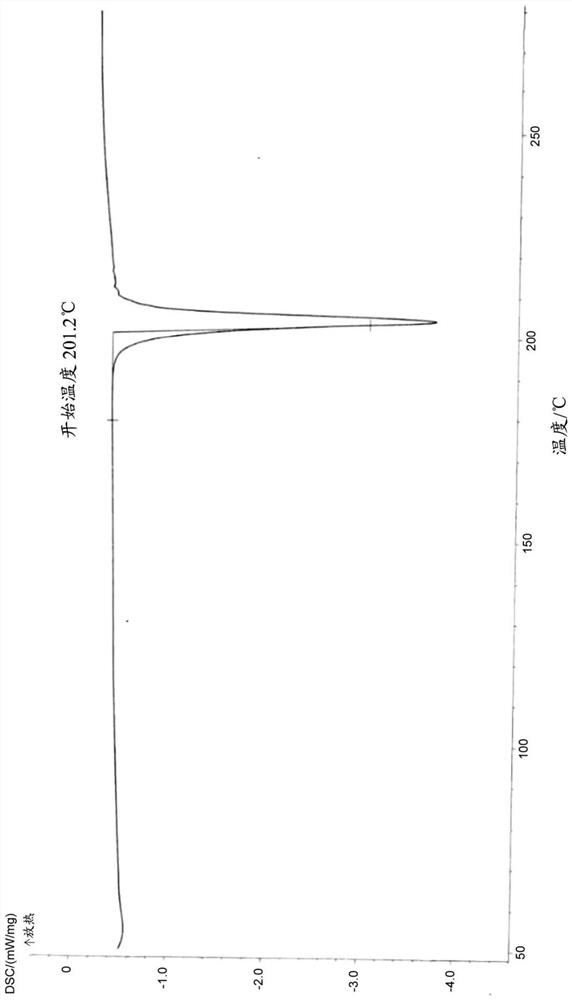

[0074] (1) Compound (R) shown in formula (I) 1 is methyl, R 2 Be methyl) besylate as API and Soluplus, magnesium stearate micronization, mix homogeneously, after making physical mixture, add polyethylene glycol P6000.

[0075] (2) Set the extrusion temperature of the twin-screw extruder to 150±10°C, start the screw after rising to the set temperature, add the physical mixture in the step (1) to the extruder, heat-melt, extrude Press and extrude in the form of spherical particles to obtain amorphous particles, which are then micronized to obtain particles with a diameter of less than 150nm.

[0076] 2. Liposome preparation:

[0077] (1) Weigh the microparticles, lecithin, cholesterol, buffe...

Embodiment 2

[0083] Compound (R) shown in embodiment 2 formula (I) 1 is methyl, R 2 Preparation of pharmaceutical composition for ethyl) administration through nasal mucosa

[0084] The liposome prescription is as shown in the table,

[0085]

[0086] Preparation Process:

[0087] 1. Microparticle preparation:

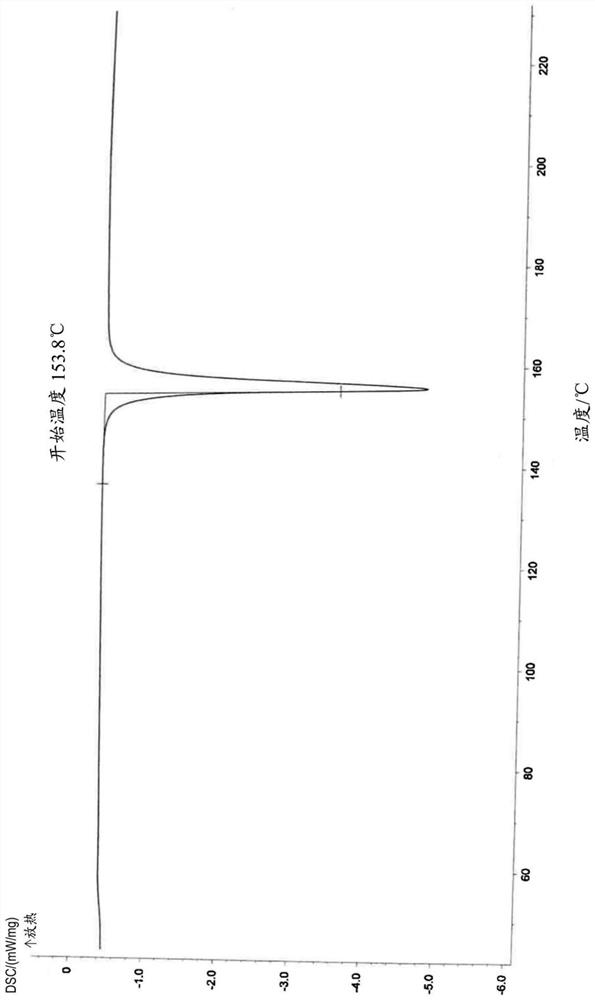

[0088] (1) Compound (R) shown in formula (I) 1 is methyl, R 2 Be ethyl) as API and K30, magnesium stearate micronization, mix uniformly, after making physical mixture, add polyethylene glycol P6000.

[0089] (2) Set the extrusion temperature of the twin-screw extruder to 160±10°C, start the screw after rising to the set temperature, add the physical mixture in the step (1) to the extruder, heat-melt, extrude Press and extrude in the form of spherical particles to obtain amorphous particles, which are then micronized to obtain particles with a diameter of less than 150nm.

[0090] 2. Liposome preparation:

[0091] (1) Weigh the prescribed amount of microparticles, lecithi...

Embodiment 3

[0097] Compound (R) shown in embodiment 3 formula (I) 1 for hydrogen, R 2 Preparation of pharmaceutical composition for nasal mucosa administration

[0098] The liposome prescription is as shown in the table,

[0099]

[0100] Preparation Process:

[0101] 1. Microparticle preparation:

[0102] (1) Compound (R) shown in formula (I) 1 for hydrogen, R 2 For methyl) as API and K90, talcum powder micronization, mix well, after making physical mixture, add polyethylene glycol P2000.

[0103] (2) Set the extrusion temperature of the twin-screw extruder to 150°C, start the screw after rising to the set temperature, add the physical mixture in step (1) to the extruder, heat-melt and extrude, It is extruded in the form of spherical particles to obtain amorphous particles, and then micronized to obtain particles with a diameter of less than 150nm.

[0104] 2. Liposome preparation:

[0105] (1) Weigh microparticles, phosphatidylcholine, cholesterol, buffer, p-phenylenediamine,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com