Enhanced polycarboxylate superplasticizer and preparation method thereof

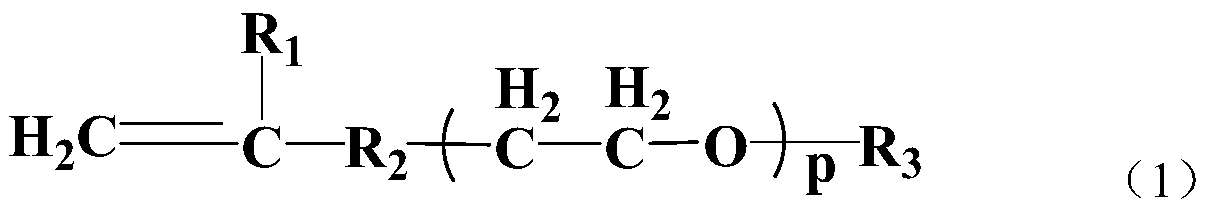

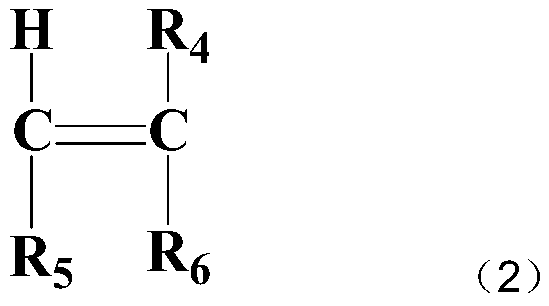

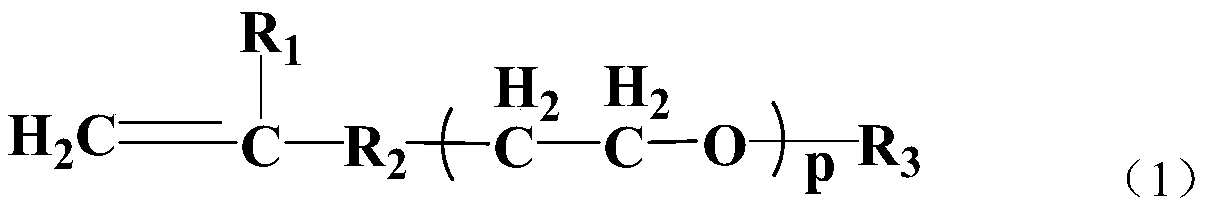

A technology of polycarboxylate and water reducer, which is applied in the field of concrete admixture, can solve the problems of poor water solubility of unsaturated silane monomer and insufficient influence of polycarboxylate water reducer on the action process, and achieve favorable dispersion ability , Increase the late strength of concrete, increase the effect of material adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] equipped with thermometer, stirrer and N 2 3000 g of A-1 (1 mol) was added to the glass reactor with the introduction tube, and the reaction vessel was purged with nitrogen gas while stirring, and the temperature was raised to 60° C. to dissolve. After the polyether is completely dissolved, accurately weigh 2.46 g of azobisisobutyronitrile, divide it into 5 parts, add 0.49 g before the reaction starts, and stir evenly. 144g of B-1 (2mol) and 1.172g of mercaptoethanol were mixed and dripped into the reactor with a peristaltic pump for 5 hours. During the reaction process, 0.49 g of azobisisobutyronitrile was added every 75 minutes, and after the addition of the materials was completed, the mixture was incubated for 1 hour to obtain prepolymer 1 with a molecular weight of 118,000.

[0055] Raise the temperature of the material in the reaction flask to 100°C and continuously feed N 2 Carry out water, add catalyst p-toluenesulfonic acid 71.72g, dropwise add 442g C-1 (2mol...

Embodiment 2

[0057] equipped with thermometer, stirrer and N 2 Add 5000 g of A-2 (1 mol) into the glass reactor of the introduction tube, purging the reaction vessel with nitrogen while stirring, and raise the temperature to 70° C. to dissolve. After the polyether is completely dissolved, accurately weigh 21.6g of potassium persulfate, divide it into 4 parts, add 5.4g before the reaction starts, and stir evenly. Mix 258g of B-1 (3mol) and 7.74g of mercaptopropanol, and drop them into the reactor with a peristaltic pump for 4 hours. During the reaction process, 5.4 g of potassium persulfate was added every 80 minutes, and after the dropwise addition of the materials was completed, the mixture was incubated for 1 hour to obtain prepolymer 2 with a molecular weight of 94,000.

[0058] Raise the temperature of the material in the reaction flask to 100°C and continuously feed N 2 Water was carried out, 110.53 g of catalyst p-toluenesulfonic acid was added, and 268.5 g of C-2 (1.5 mol) was add...

Embodiment 3

[0060] equipped with thermometer, stirrer and N 2 Into the glass reactor of the pipe, add 6500g A-3 (1mol), while stirring, purging the reaction vessel with nitrogen gas, divide 464g B-3 (4mol) into 3 equal parts, add 154.7g before the reaction starts, and Heat up to 80°C to dissolve. After the material is completely dissolved, accurately weigh 49.67 g of azobisisoheptanonitrile, divide it into 4 parts, and add 12.4 g before the reaction starts, and stir evenly. 19.8g of thioglycolic acid was dripped into the reactor with a peristaltic pump, and the dropping time was 3 hours. During the reaction, 154.7 g of B-3 and 12.4 g of azobisisoheptanonitrile were added every 60 minutes. After the addition of thioglycolic acid was completed, 12.4 g of azobisisoheptanonitrile was added, and the mixture was incubated for 1 hour to obtain prepolymer 3 with a molecular weight of 73,500.

[0061] Raise the temperature of the material in the reaction flask to 100°C and continuously feed N ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com