A kind of antibacterial low-sulfur diesel oil lubrication improver and preparation method thereof

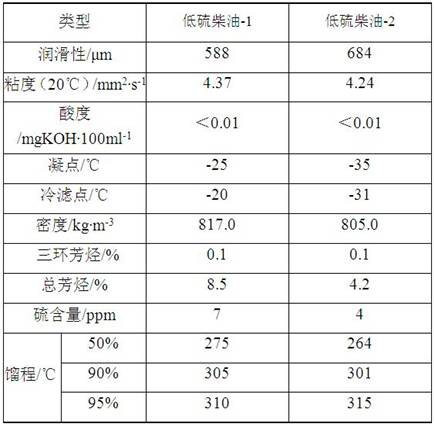

A lubrication improver and low-sulfur diesel technology, which is applied in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve the problems of diesel bacteria, worn injectors, engine failures, etc., so as to broaden the source of raw materials and reduce condensation. point, improve the effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

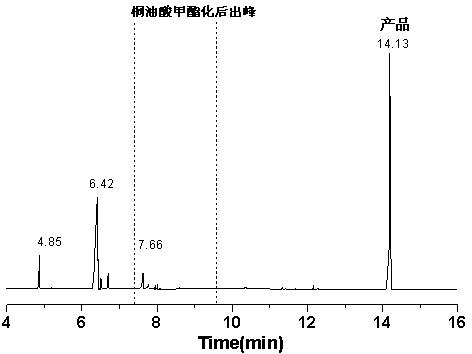

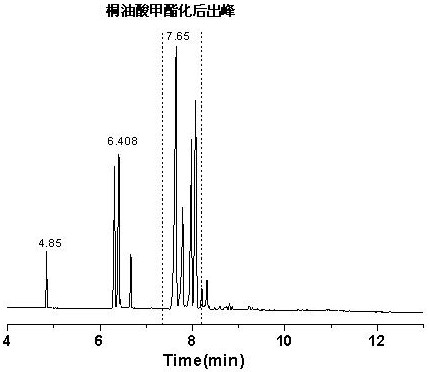

[0031] Put 126g of 3-n-butenal and 0.25g of hydroquinone into the reaction kettle, start stirring at a stirring speed of 300rpm and raise the temperature to 135°C for mixing. Gradually add 500 g of tungoleic acid (commercial tungoleic acid, Anhui Ruifengde Oil Deep Processing Co., Ltd., model: T160) dropwise into the reaction kettle, so that the addition of tungoleic acid is completed within 2 hours, and the dropping rate is basically uniform. After the addition, continue to react for 9 hours. After finishing the reaction, distill under reduced pressure at 200°C for 2 hours at a pressure of 65 Pa to obtain the improver product. After calculation, the conversion rate of carbon-carbon conjugated double bond of oleic acid is 76.8%. After testing, the acid value of the product is 118.5mgKOH / g, and the freezing point is -25.6°C. Depend on figure 1 and figure 2 It can be seen that a new characteristic peak of the compound appeared at the outflow time of 14.13 minutes, which prov...

Embodiment 2

[0033] Put 63g of 3-butenal and 0.15g of hydroquinone into the reaction kettle, start stirring at a stirring speed of 300rpm, and raise the temperature to 130°C for mixing. Gradually add 500g of tungoleic acid (commercial tungoleic acid) to the reaction kettle dropwise, so that the addition of tungoleic acid is completed within 1 hour, and the dropping rate is basically uniform. Distilled under reduced pressure for 2h to obtain the improver product. The conversion rate of the carbon-carbon conjugated double bond of oleic acid is 74.9%, the acid value of the product is 119.7mgKOH / g, and the freezing point is -25.4°C.

Embodiment 3

[0035] Put 252g of 3-n-butenal and 0.5g of hydroquinone into the reaction kettle, start stirring at a stirring speed of 300rpm, and raise the temperature to 150°C for mixing. Gradually add 500g of tungoleic acid (commercial tungoleic acid) dropwise into the reaction kettle, so that the addition of tungoleic acid is completed within 3 hours, and the dropping rate is basically uniform. Distilled under reduced pressure for 2h to obtain the improver product. The conversion rate of carbon-carbon conjugated double bond of oleic acid is 76.2%, the acid value of the product is 117.8mgKOH / g, and the freezing point is -25.9℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com