Linear-crosslinked multi-component copolymerized polyamide reverse osmosis membrane for sea water desalination and preparation method thereof

A technology of copolymerized polyamide and multicomponent copolymerization, which is applied in the field of linear-crosslinked multicomponent copolymerized polyamide reverse osmosis membrane for seawater desalination and its preparation, and can solve the problem of large intermolecular free volume, low sodium chloride rejection, water The flux cannot be further improved, etc., to achieve the effect of high retention rate, good mechanical and physicochemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

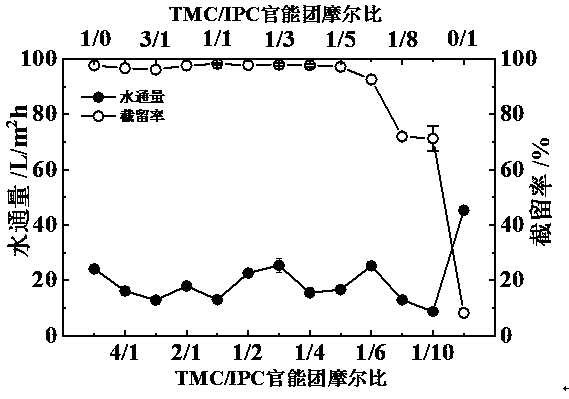

[0036] Example 1: The organic phase solution used in the interfacial polymerization reaction in the experiment is n-hexane solution of trimesoyl chloride and diacid chloride monomers in different proportions. The MPD / TMC polyamide reverse osmosis composite membrane was prepared, the concentration of TMC was 0.1 wt%, the mass ratio of MPD and TMC was 20:1, and the molar ratio of amine groups to acid chloride groups was calculated to be 33:1. The interfacial reaction time is 60 seconds, and the temperature range of the interfacial polymerization reaction is 25 degrees Celsius. In the experiment, the molar ratio of the amine group and the acid chloride group was kept constant, and the proportion of the acid chloride functional group occupied by the TMC and the diacid chloride monomer was adjusted. Taking isophthaloyl chloride (IPC) and trimesoyl chloride as organic phase monomers as an example, the molar ratios of the acid chloride functional groups occupied by TMC and IPC are 1:...

example 2

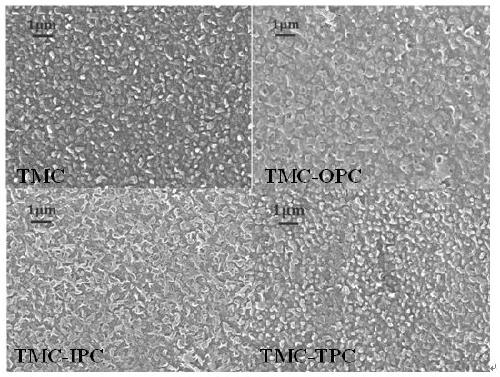

[0046] Example 2: SEM characterization of the surface of the reverse osmosis membrane prepared by trimesoyl chloride, trimesoyl chloride, ortho-, m-, and terephthaloyl chloride. For pure trimesoyl chloride, the granular structure and the "leaf" structure in the picture coexist, and the overall structure is densely arranged; for the samples of trimesoyl chloride and isophthaloyl chloride, the "leaf" structure is mixed with some granular structure, showing a "peak-trough" rough shape; trimesoyl chloride and phthaloyl chloride samples, the surface forms a convex structure, and the inside of the convex part has a depression or a hole-like structure; while for the trimesoyl chloride and phthaloyl chloride samples, For the samples of triformyl chloride and terephthaloyl chloride, the "leaf-like" structure was significantly reduced, showing a fragmented and dense distribution.

example 3

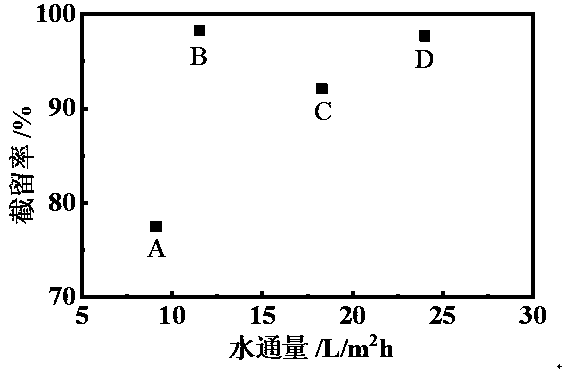

[0047] Example 3: Since the base material will have a great influence on the separation performance of the prepared reverse osmosis membrane, the selection of the base material is carried out first, and US020, electrospun membrane, imported PS20 and domestic PS20 are selected for comparison. Among them, the average pore diameter of the microfiltration electrospun membrane is 0.5 micron; the average pore diameter of the ultrafiltration membrane is 25 nanometers. MPD / TMC reverse osmosis membranes were prepared through the interfacial polymerization step in Example 1 using different substrates. Studies have shown that substrate PS20 works best.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com