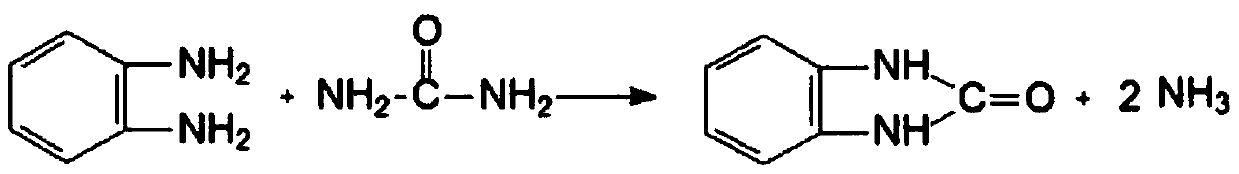

Method for preparing benzimidazolone in water solvent

A technology of benzimidazolone and water solvent, which is applied in the field of biological polypeptide condensing agent by-product treatment, can solve the problems of low yield, poor safety, high production cost, etc., and achieve the effect of low price, easy acquisition, and material cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add the aqueous solution of the auxiliary agent into the reaction bottle, the auxiliary agent is sodium salt, the mass ratio of the auxiliary agent to water in the aqueous auxiliary agent solution is 1:8, start stirring, and add o-phenylenediamine and urea when the temperature rises to 130 °C, urea and o-phenylenediamine The mass ratio of phenylenediamine is 1:1.1, the mass ratio of o-phenylenediamine to the water initially added to the aqueous solution of the auxiliary agent in the reaction bottle is 2:5, and the reaction is carried out at 130°C for 5 hours. After the reaction is completed, the aqueous solution of the auxiliary agent is added for 14 , filtered with suction and rinsed with water, the filter cake was dried to obtain benzimidazolone, and the filtrate, namely the mother liquor, was concentrated and used mechanically. The yield of benzimidazolone was 99.04%, and the purity was 99.32%.

Embodiment 2

[0025] Add the aqueous solution of the auxiliary agent into the reaction bottle, the auxiliary agent is magnesium salt, the mass ratio of the auxiliary agent to water in the aqueous auxiliary agent solution is 2:15, start stirring, and add o-phenylenediamine and urea when the temperature rises to 105°C, urea and o-phenylenediamine The mass ratio of phenylenediamine is 1:1, the mass ratio of o-phenylenediamine to the water initially added to the aqueous solution of the auxiliary agent in the reaction bottle is 1:3, and the reaction is carried out at 105°C for 3 hours. After the reaction is completed, the aqueous solution of the auxiliary agent is added. Suction filtration and rinse with water, the filter cake is dried to benzimidazolone, the filtrate, namely the mother liquor, is concentrated and used mechanically, the yield of benzimidazolone is 99.19%, and the purity is 99.61%.

Embodiment 3

[0027] Add the aqueous solution of the auxiliary agent into the reaction bottle, the auxiliary agent is a mixture of aluminum salt and zinc salt, the mass ratio of the auxiliary agent to water in the aqueous auxiliary agent solution is 1.1:20, start stirring, and add o-phenylenediamine and Urea, the mass ratio of urea to o-phenylenediamine is 1:1.2, the mass ratio of o-phenylenediamine to the water initially added to the auxiliary agent aqueous solution in the reaction bottle is 1:4, and the reaction is carried out at 90°C for 7 hours. After the reaction is completed, Aqueous additive solution is added, suction filtered and rinsed with water, the filter cake is dried to obtain benzimidazolone, and the filtrate, mother liquor, is concentrated and used mechanically. The yield of benzimidazolone is 99.53%, and the purity is 99.78%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com