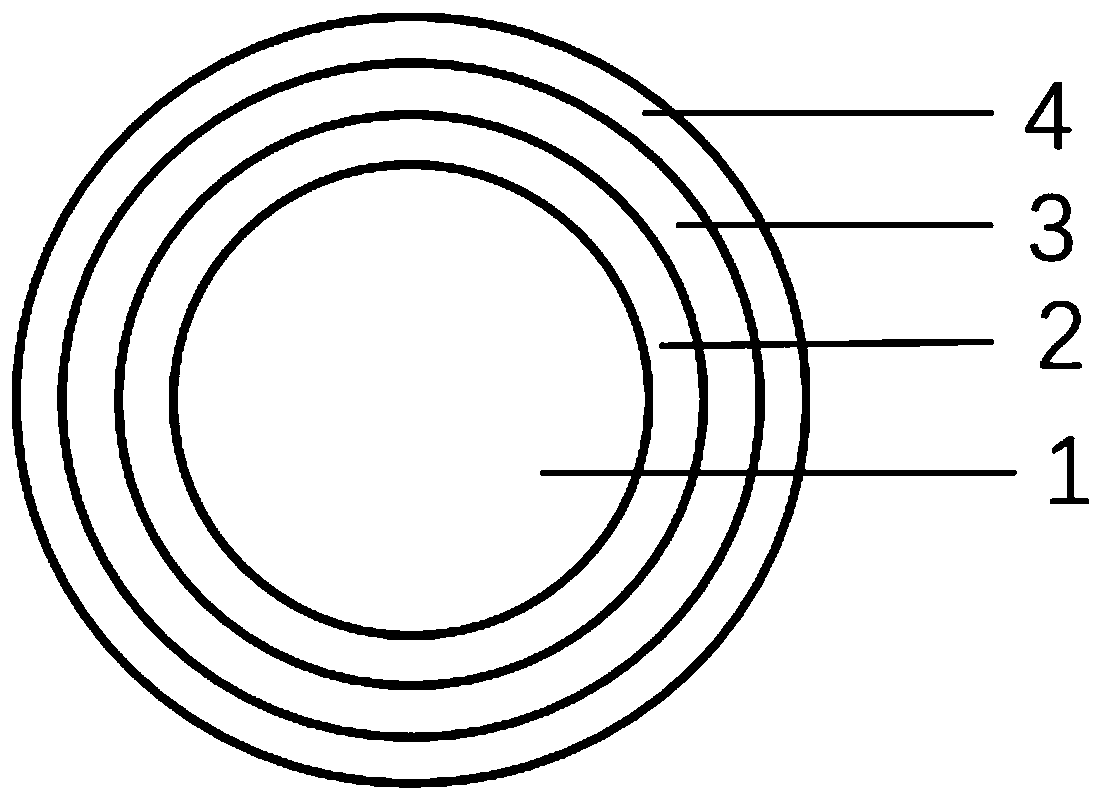

Multi-layer heat storage and preservation microcapsule applied to fabrics and preparation method

A technology of microcapsules and heat storage, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of leakage of phase change energy storage materials in the core of microcapsules, insufficient shell thickness, poor heat resistance, etc., and achieve good Mechanical strength, high cross-linking reaction efficiency, and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

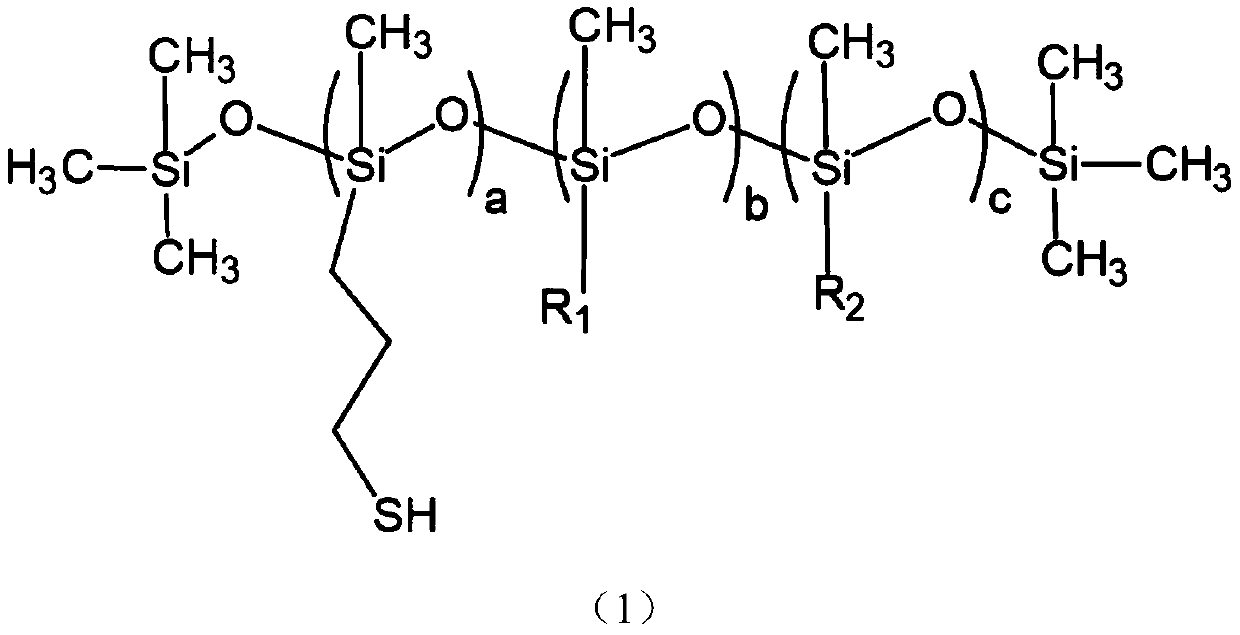

[0033] Mix 0.1 part of 1,3,5-benzenetricarboxylic acid chloride, 10 parts of n-eicosane, 0.8 part of OP-10 and 0.2 part of sodium dodecylbenzene sulfonate, heat to 45°C, add 16 parts of 45 °C water forms an emulsion. Add 0.3 parts of mercaptoamino silicone oil to the emulsion, stir for 2.5 hours, separate and wash with water to obtain single-layer microcapsules 1.

[0034] 1 part of single-layer microcapsule 1 is dispersed in 3 parts of absolute ethanol, add 0.006 part of carboxyvinyl silicone oil and 0.002 part of benzoin dimethyl ether, and irradiate with ultraviolet light with a main wavelength of 365nm and a light intensity of 8mW / cm for 3 minutes to separate the alcohol Wash to obtain double-layer microcapsules 1 .

[0035] 1 part of double-layer microcapsule 1 is dispersed in 3 parts of absolute ethanol, 0.1 part of aziridine cross-linking agent is added, stirred for 2 hours, separated, washed with alcohol, and dried to obtain multi-layer heat storage and heat preservat...

Embodiment 2

[0037] Mix 0.5 parts of 1,3,5-benzenetricarboxylic acid chloride, 10 parts of n-docosane, 0.9 parts of OP-10 and 0.3 parts of sodium dodecylbenzenesulfonate, heat to 55°C, and add 20 parts under high-speed stirring Water at 55°C forms an emulsion. Add 1.5 parts of mercaptoamino silicone oil to the emulsion, stir for 1 hour, separate and wash with water to obtain single-layer microcapsules 2.

[0038] Disperse 1 part of single-layer microcapsule 2 in 6 parts of isopropanol, add 0.015 part of mercaptoamino silicone oil and 0.003 part of benzoin ether, irradiate with ultraviolet light with a main wavelength of 365 nm and a light intensity of 8 mW / cm for 4 minutes, separate and wash with alcohol, Obtain bilayer microcapsules 2.

[0039] 1 part of double-layer microcapsule 2 was dispersed in 5 parts of isopropanol, 0.12 part of aziridine cross-linking agent was added, stirred for 2 hours, separated, washed with water, and dried to obtain multi-layer heat-storage and thermal insula...

Embodiment 3

[0041] Mix 1 part of 1,3,5-benzenetricarboxylic acid chloride, 10 parts of paraffin, 1 part of OP-10 and 0.3 parts of sodium dodecylbenzenesulfonate, heat to 70°C, add 24 parts of 70°C water under high-speed stirring , forming an emulsion. Add 3 parts of mercaptoamino silicone oil to the emulsion, stir for 0.5 hour, separate and wash with water to obtain single-layer microcapsule 3.

[0042] Disperse 1 part of single-layer microcapsule 3 in 7 parts of absolute ethanol, add 0.08 part of carboxyvinyl silicone oil and 0.003 part of benzoin ethyl ether, irradiate with ultraviolet light with a main wavelength of 365 nm and a light intensity of 5 mW / cm for 7 minutes, separate and wash with alcohol, Obtain bilayer microcapsules 3.

[0043] 1 part of double-layer microcapsule 3 is dispersed in 7 parts of absolute ethanol, 0.1 part of aziridine cross-linking agent is added, stirred for 1.5 hours, separated and washed with alcohol, and dried to obtain multi-layer thermal storage and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com