A joint method of reducing subsidence by grouting in the inner capsule bag and sealing water-conducting fissures

A water-conducting fissure zone and grouting technology, which is used in earth-moving drilling, sealing/packing, wellbore/well components, etc., can solve problems such as rising cost of grouting materials, damage to ecological environment, and difficulty in grouting construction. To achieve the effect of controlling uneven settlement of overlying rock, reducing the risk of pollution, and reducing potential risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

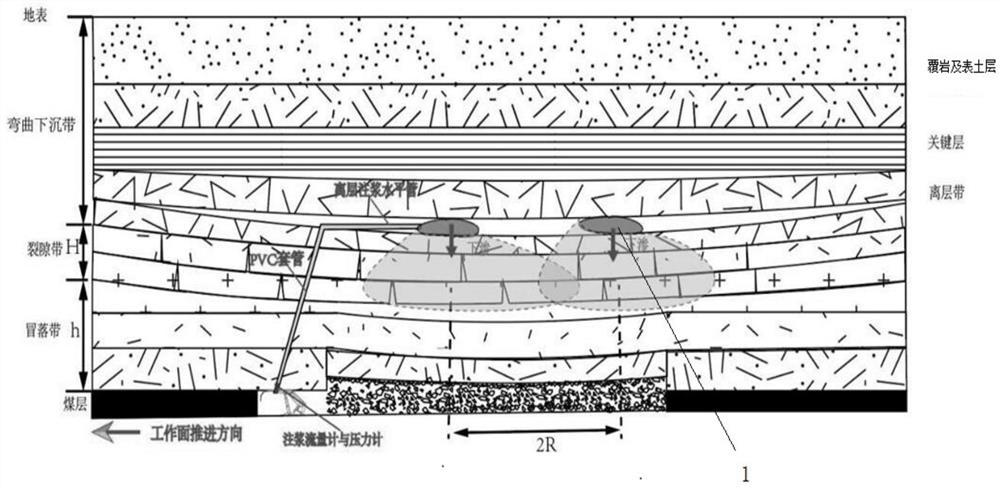

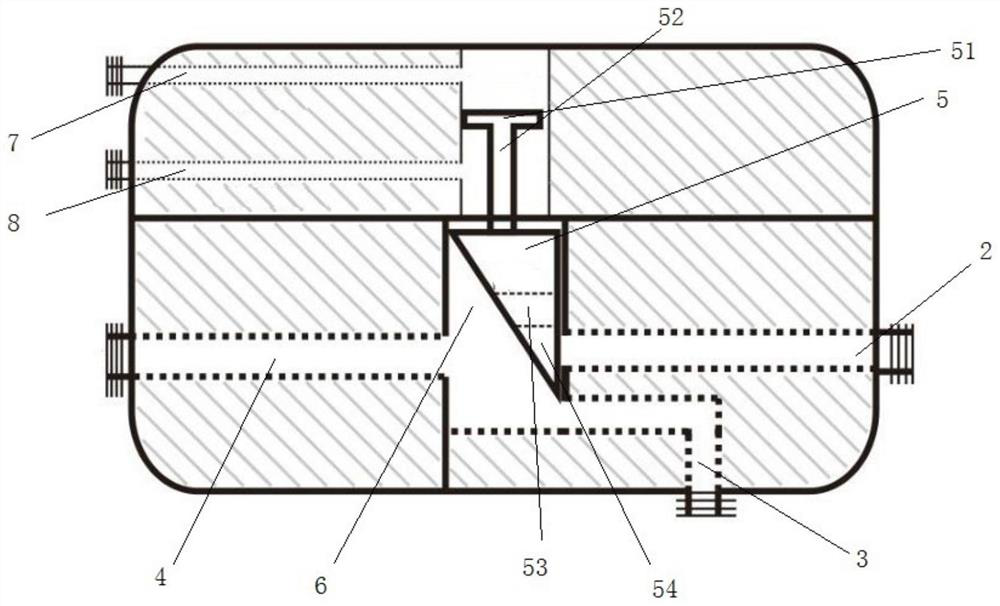

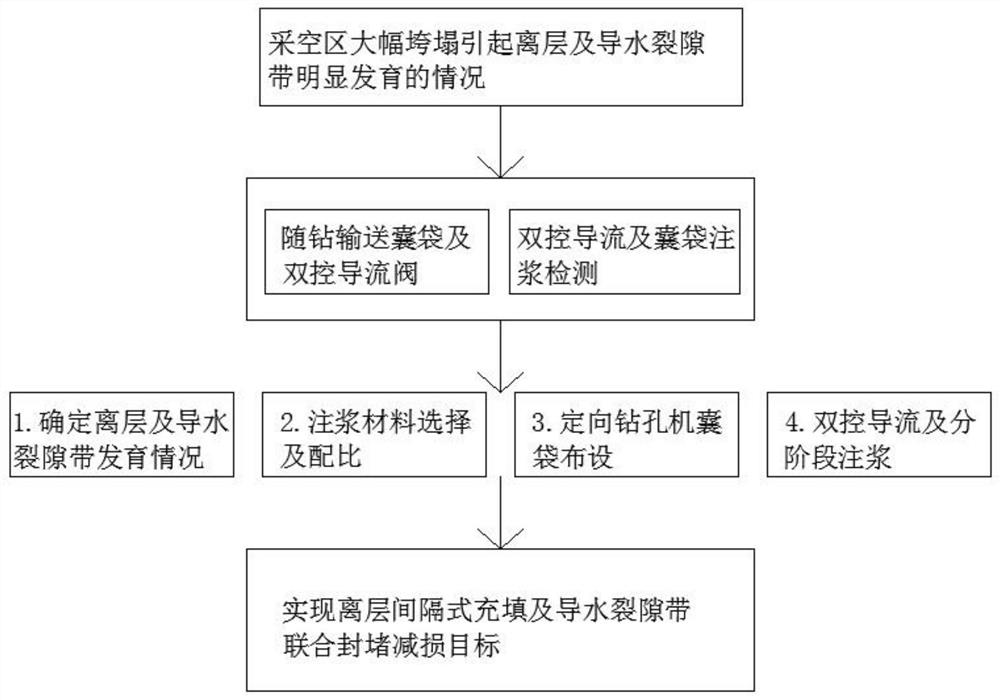

[0035] refer to Figure 1~3 , in view of the obvious development of the abscission layer and water-conducting fissure zone caused by the large collapse of the goaf, a joint subsidence reduction method of grouting in the inner pocket 1 of the abscission layer and sealing of the water-conducting fissure zone is provided, which specifically includes the following steps:

[0036] The first step is to use the drill pipe to carry out the directional drilling operation in the well, and based on the drilling endoscope observation method and experience judgment, determine the spatial distribution of the separation layer and the height of the water-conducting fracture zone, and then determine the grouting required for the grouting pocket 1 Grouting volume and grouting pressure, and determine the grout ratio based on laboratory tests to ensure that its fluidity, initial setting time and grouting strength can meet the predetermined requirements; while the grouting amount of the water-condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com