Low-loss soft magnetic powder core and preparation method thereof

A low-loss, magnetic powder core technology, applied in the manufacture of inductors/transformers/magnets, magnetic materials, magnetic objects, etc., can solve the problems of poor superposition performance, large eddy current loss, high loss, etc., and achieve low cost, simple preparation process, and low cost. Effect of High Frequency Power Loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

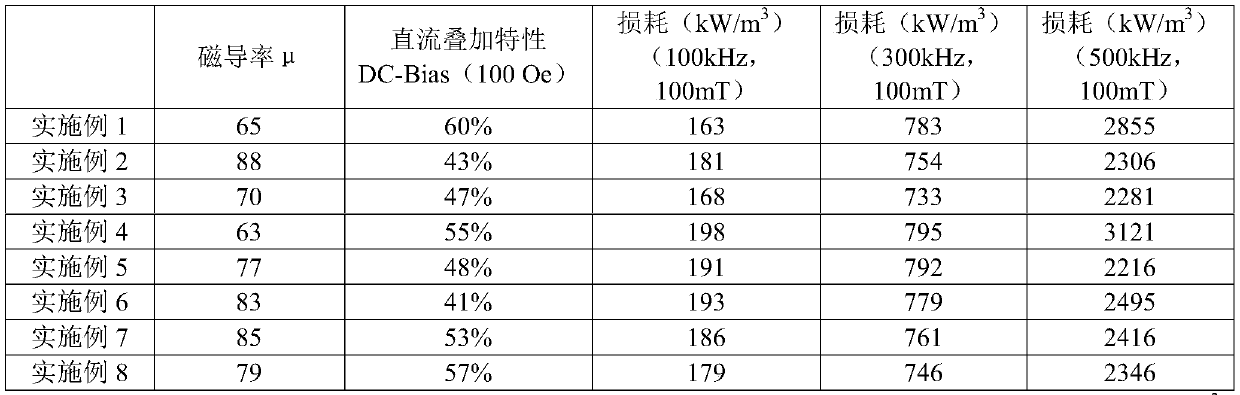

Examples

Embodiment 1

[0033] A low-loss soft magnetic powder core, which is made of nanocrystalline powder, the D of the magnetic powder 90 = 45 μm, D 50 = 14 μm;

[0034] In the nanocrystalline powder, the content of Si is 13.5at%, the content of B is 9.0at%, the content of Nb is 3.0at%, the content of Cu is 1.0at%, the content of P is 0.01at%, and the content of C is 0.01 at%, the balance is iron.

[0035] A method for preparing a low-loss soft magnetic powder core, comprising the following steps:

[0036] a) Powder annealing: the above-mentioned magnetic powder is annealed in a protective atmosphere mixed with argon and hydrogen, the temperature is 550°C, and the heat treatment time is 2 hours;

[0037] b) Insulation coating: add 0.5wt% passivator phosphoric acid acetone solution of the magnetic powder weight to the magnetic powder after the above-mentioned treatment for passivation treatment, mix until dry, then add 0.08wt% kaolin by the magnetic powder weight therein The mixed aqueous disp...

Embodiment 2

[0042] A low-loss soft magnetic powder core, which is made of a mixed magnetic powder composed of gas-atomized FeSiAl powder and amorphous powder at a weight ratio of 8:2, and the D of the magnetic powder 90 =75μm, D 50 = 30 μm;

[0043] In the gas-atomized FeSiAl powder, the content of Si is 7.5wt.%, the content of Al is 3.5wt.%, and the balance is iron;

[0044] In the amorphous powder, the content of Si is 10 at%, the content of B is 15.0 at%, the content of P is 10.0 at%, the content of C is 5.0 at%, the content of Cr is 5.0 at%, and the balance is iron.

[0045] A method for preparing a low-loss soft magnetic powder core, comprising the following steps:

[0046] a) Powder annealing: heat-treat the above-mentioned magnetic powder under an argon protective atmosphere at a temperature of 850° C. and a heat-treatment time of 6 hours;

[0047] b) Insulation coating: Add 0.01% sodium hydrogen phosphate aqueous solution of the magnetic powder weight to the magnetic powder aft...

Embodiment 3

[0052] A low-loss soft magnetic powder core, which is made of mixed magnetic powder composed of gas-atomized FeSiAl powder and gas-atomized FeNiMo powder at a weight ratio of 5:5, and the D of the magnetic powder 90 = 45 μm, D 50 = 13 μm;

[0053] In the gas-atomized FeSiAl powder, the content of Si is 12.5wt.%, the content of Al is 8.5wt.%, and the balance is iron;

[0054] In the gas-atomized FeNiMo powder, the content of Fe is 15.0wt.%, the content of Mo is 2.0wt.%, and the balance is Ni.

[0055] A method for preparing a low-loss soft magnetic powder core, comprising the following steps:

[0056] a) Powder annealing: heat-treat the above-mentioned magnetic powder in a protective atmosphere mixed with nitrogen and hydrogen at a temperature of 700° C. for 2 hours;

[0057] b) Insulation coating: Add 0.3wt% aluminum dihydrogen phosphate aqueous solution of the magnetic powder weight to the magnetic powder after the above treatment for passivation treatment, mix until dry, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| core loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com