Separation method of metal substrate light-emitting device wafer

A technology for metal substrates and light-emitting devices, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of metal slag easily splashing into the light-emitting area, increase device leakage, etc., and achieve multi-chip output, The effect of reducing yield loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

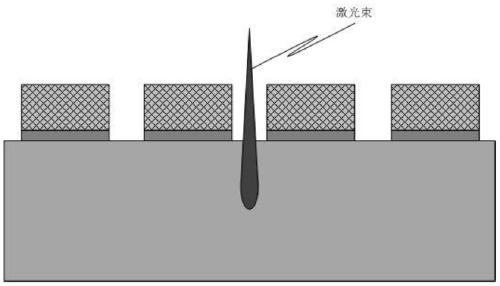

[0012] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

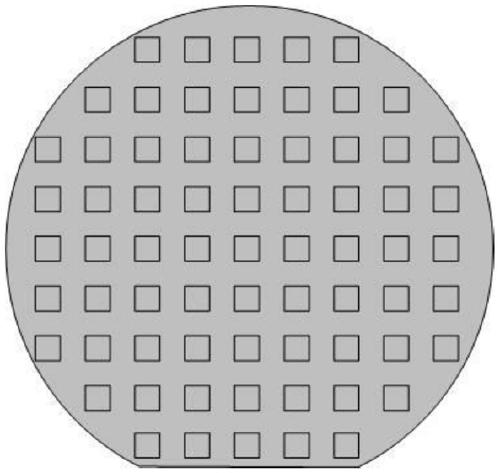

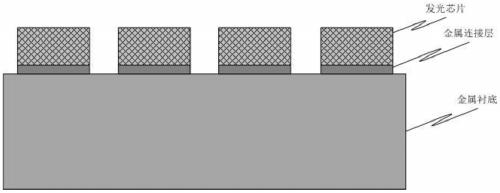

[0013] Usually, the light-emitting chip pattern existing on the front of the wafer can provide a reference for the scribing path of the laser, while the back is usually smooth and has no pattern. The feature of the present invention is that an auxiliary pattern is formed on the back of the metal substrate in combination with the pattern on the front of the substrate. It is used to guide the movement of the laser, and the laser is ablated at a suitable position on the back, and then aligned with the laser ablation line on the back, and splits on the front.

[0014] The first step is to provide a GaN-based light-emitting chip wafer with a WCu substrate. The structure includes: a 210um thick WCu substrate, a metal connection layer composed of Au, Sn, and Ti, and a GaN-based light-emitting chip; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap