Modified cassava starch-polycarboxylic acid composite water reducing agent

A composite water reducing agent, tapioca starch technology, applied in the field of building materials, can solve problems such as difficulty in meeting green and environmental protection, product toxicity, non-biodegradable water reducing performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

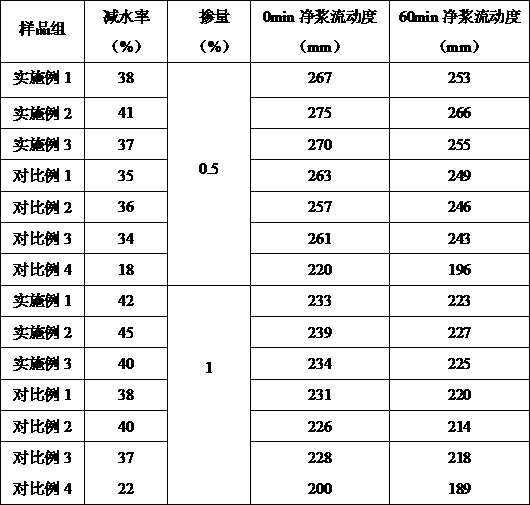

Examples

Embodiment 1

[0043] A modified tapioca starch-polycarboxylic acid composite water reducer, comprising the following raw materials in parts by weight: 20 parts of modified tapioca starch, 30 parts of sodium hydroxide, 4 parts of retarder, 2.5 parts of defoamer, primer Air agent 5.5 parts.

[0044] The retarder comprises the following components in parts by weight: 60 parts of sodium gluconate, 30 parts of sodium citrate, 29 parts of sodium tripolyphosphate, 19 parts of sodium pyrophosphate, 3 parts of ammonium borate, ferrous sulfate 2 parts, 5 parts of magnesium sulfate.

[0045] The defoamer includes the following components in parts by weight: 30 parts of hydrogen silicone oil, 40 parts of high-carbon alcohol fatty acid ester complex, 17 parts of polyoxyethylene polyoxypropylene pentaerythritol ether, octamethylcyclotetrasilane 10 parts of oxane, 5 parts of polyether silicone oil and 3 parts of polyoxypropylene polyoxyethylene glyceryl ether.

[0046] The air-entraining agent includes ...

Embodiment 2

[0054] A modified tapioca starch-polycarboxylic acid composite water reducer, comprising the following raw materials in parts by weight: 25 parts of modified tapioca starch, 100 parts of sodium hydroxide, 2 parts of retarder, 4 parts of defoamer, primer Air agent 3 parts.

[0055] The retarder comprises the following components in parts by weight: 48 parts of sodium gluconate, 32 parts of sodium citrate, 25 parts of sodium tripolyphosphate, 16 parts of sodium pyrophosphate, 5.5 parts of ammonium borate, ferrous sulfate 3 parts, 2.5 parts of magnesium sulfate.

[0056] The defoamer includes the following components in parts by weight: 50 parts of hydrogen silicone oil, 28 parts of high-carbon alcohol fatty acid ester complex, 14 parts of polyoxyethylene polyoxypropylene pentaerythritol ether, octamethylcyclotetrasilane 12 parts of oxane, 6.5 parts of polyether silicone oil and 4.5 parts of polyoxypropylene polyoxyethylene glyceryl ether.

[0057] The air-entraining agent incl...

Embodiment 3

[0065] A modified tapioca starch-polycarboxylic acid composite water reducer, comprising the following raw materials in parts by weight: 35 parts of modified tapioca starch, 120 parts of sodium hydroxide, 6 parts of retarder, 0.5 part of defoamer, primer Air agent 1 part.

[0066] The retarder comprises the following components in parts by weight: 43 parts of sodium gluconate, 37 parts of sodium citrate, 22 parts of sodium tripolyphosphate, 13 parts of sodium pyrophosphate, 8 parts of ammonium borate, ferrous sulfate 4 parts, 1 part of magnesium sulfate.

[0067] The defoamer includes the following components in parts by weight: 65 parts of hydrogen silicone oil, 20 parts of high-carbon alcohol fatty acid ester complex, 10 parts of polyoxyethylene polyoxypropylene pentaerythritol ether, octamethylcyclotetrasilane 15 parts of oxane, 9 parts of polyether silicone oil and 6 parts of polyoxypropylene polyoxyethylene glyceryl ether.

[0068] The air-entraining agent includes the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com