Force-induced responsive cross-linked polymer

A technology of cross-linked polymers and polymers, applied in the field of cross-linked polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

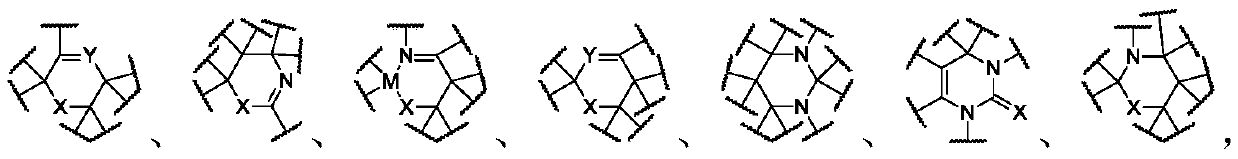

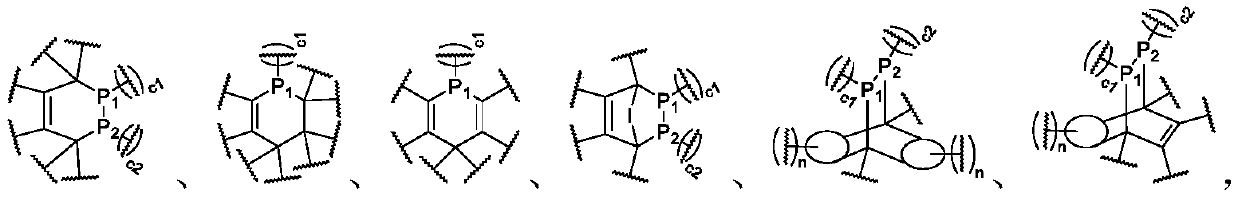

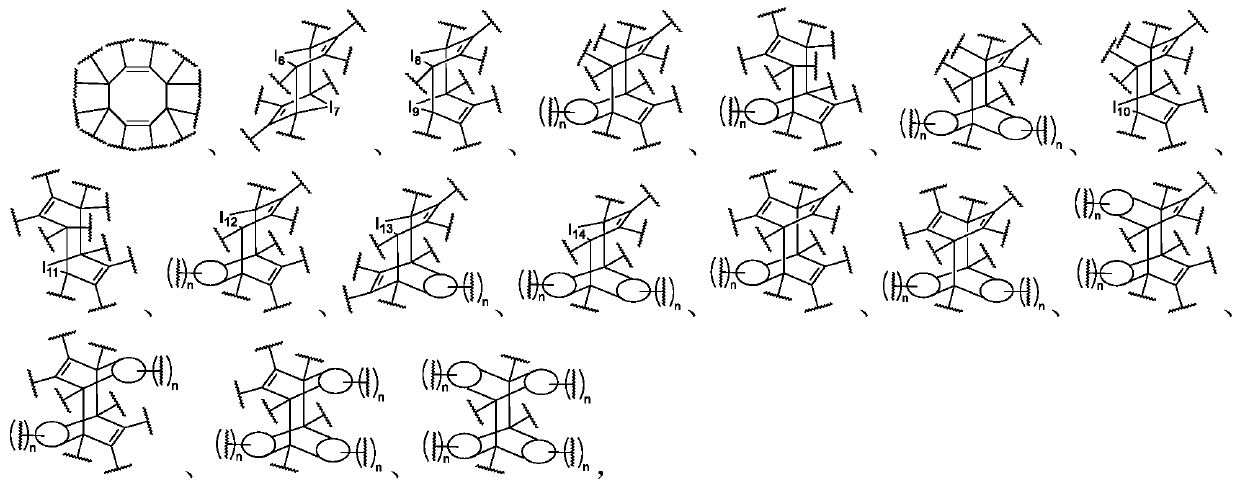

Method used

Image

Examples

preparation example Construction

[1816] In the preparation process of the polymer, three methods of mechanical foaming, physical foaming and chemical foaming are mainly used to foam it.

[1817] Among them, the mechanical foaming method is to introduce a large amount of air or other gases into the emulsion, suspension or solution of the polymer with the help of strong stirring during the preparation of the polymer to make it a uniform foam, and then through physical or Chemical changes shape it into foam. In order to shorten the molding cycle, air can be introduced and emulsifiers or surfactants can be added.

[1818]Wherein, the physical foaming method is to use physical principles to realize the foaming of the polymer during the preparation of the polymer, which includes but is not limited to the following methods: (1) inert gas foaming method, that is, under pressure Under normal circumstances, the inert gas is pressed into the molten polymer or pasty material, and then the pressure is reduced and the tem...

Embodiment 1

[1829]

[1830] Weigh 1 molar equivalent of compound (a) and 1 molar equivalent of compound (b), use dichloromethane as solvent, fully stir and dissolve, then place the reaction solution under a 300W ultraviolet lamp for 30min to make mercapto-alkene click reaction to produce product 1. Weigh 1 molar equivalent of polyacrylic acid (molecular weight: 1000) in a dry and clean flask, heat to 100°C to remove water and oxygen with nitrogen gas for 1 h, and add 0.01 molar equivalent of N,N-diisopropylcarbodiimide, 0.01 Molar equivalent of diphenyl-4-phenylthiophenylsulfonium salt, then add 0.2 molar equivalent of 1,10-decanediol, 0.2 molar equivalent of product 1, 0.2 molar equivalent of methanol, 5wt% plant fiber, 5wt% sulfuric acid Barium and 5wt% talc continued to react for 1 hour. After the reaction, the polymer sample was placed in a suitable mold, dried in a vacuum oven for 24 hours, and then cooled to room temperature to obtain a polyester elastomer with high elasticity. ...

Embodiment 2

[1832]

[1833] Add 5 molar equivalents of methyl acrylate, 1 molar equivalent of compound (a), 1 molar equivalent of compound (b), 0.01 molar equivalent of 1,10-decadiene, 0.05 molar equivalent of azobisisobutyronitrile, 0.1 Molar equivalent parts of tetramethylethylenediamine (TEMED), stirred and mixed evenly, heated to 80°C, reacted for 2h, then added 5wt% cellulose nanocrystals, reacted for 2h, and filtered under reduced pressure to obtain a solid polymer sample. Putting the polymer sample into the mold, heating and pressing, a polymer material with certain flexibility can be obtained. When the material is bent, the color at the bend becomes orange-red, and it has strong fluorescence under ultraviolet light. After bending to a certain extent, the bending stress of the polymer begins to rise. This is due to the reaction of the ring-opened sulfhydryl group and the ring-opened double bond to form a secondary crosslink, forming a force-induced enhancement, which can be used ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com