Electromagnetic ultrasonic probe for detecting ultrahigh-temperature casting and forging piece and online rapid detection method

An electromagnetic ultrasonic, casting and forging technology, applied in the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, use sound waves/ultrasonic waves/infrasonic waves for material analysis, and measurement devices, etc. It can solve problems such as the inability to achieve continuous online detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

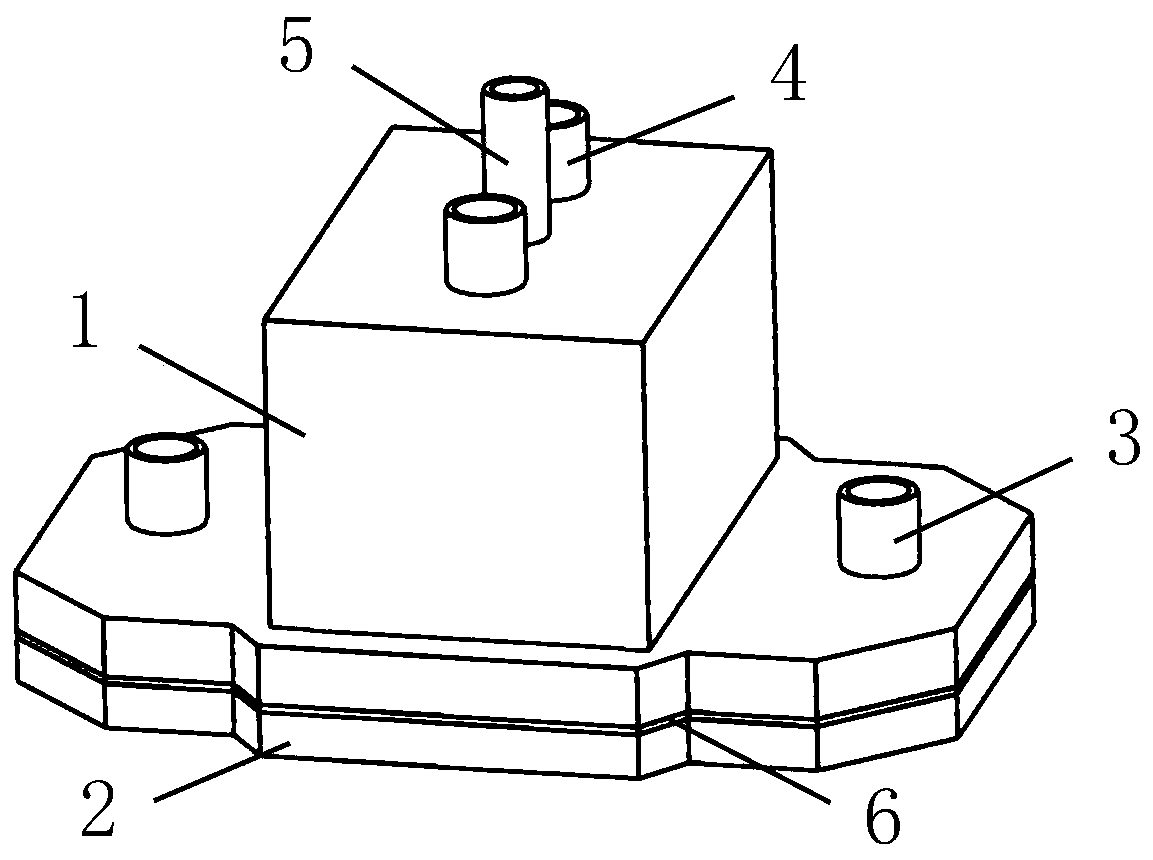

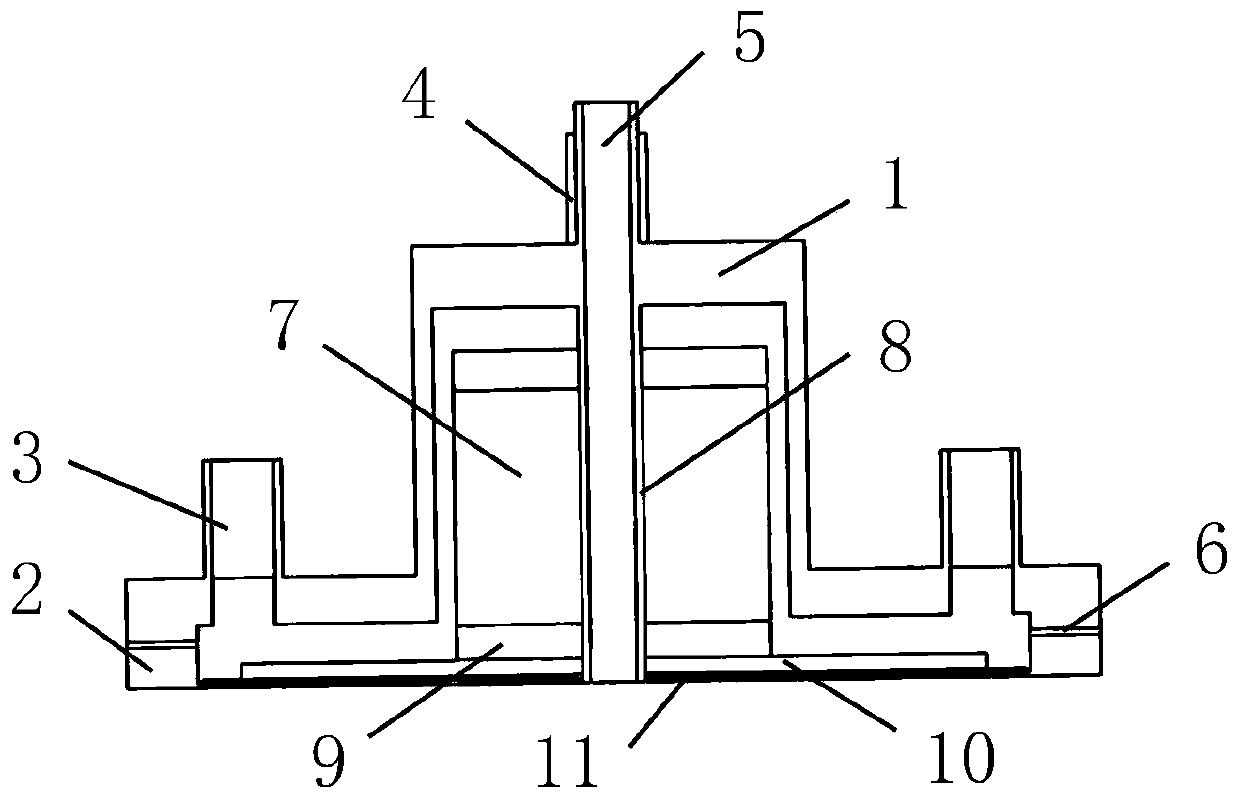

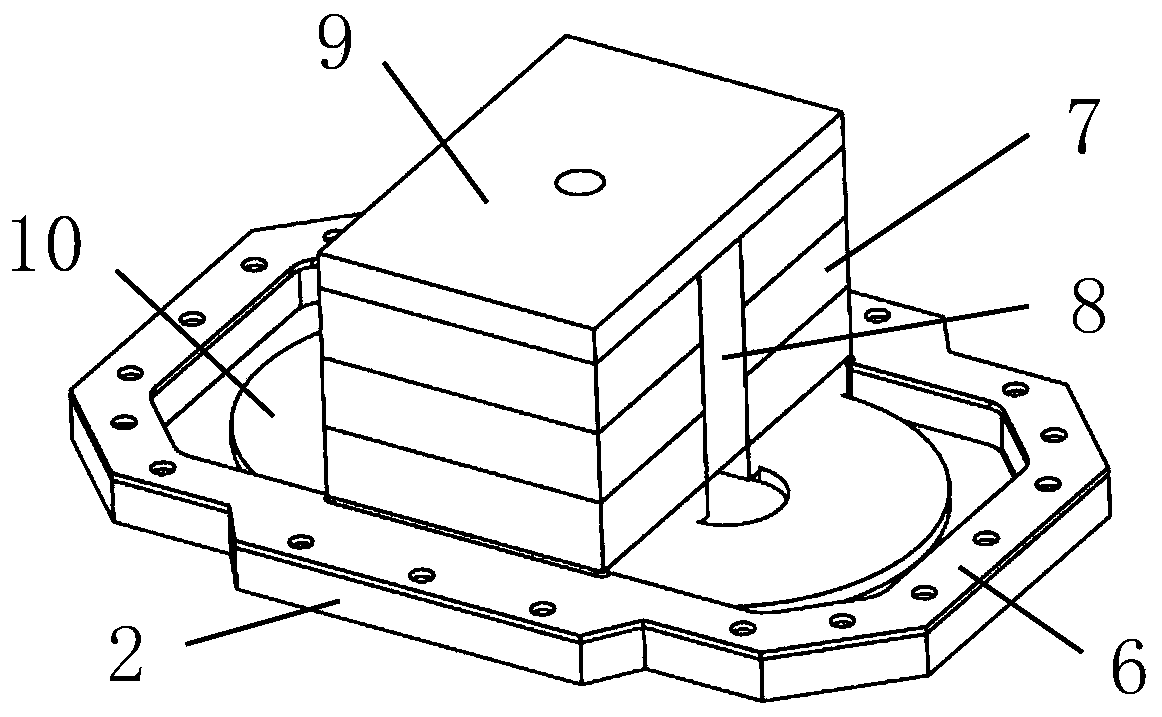

[0061] Such as Figure 1 to Figure 6 As shown, this embodiment provides an electromagnetic ultrasonic probe for ultra-high temperature casting and forging detection, including:

[0062] Probe housing (1, 2);

[0063] a permanent magnet group (7, 8) arranged in the cavity of the probe housing (1, 2);

[0064] The corundum sheet 11 arranged in the hollowed-out area at the bottom of the probe housing (1, 2);

[0065] The exciting / receiving coil 10 arranged on the top of the corundum sheet 11;

[0066] The hollow tube 5 passing through the probe shell, the permanent magnet group (7, 8), the exciting / receiving coil 10, and the corundum sheet 11 in sequence;

[0067] A number of water inlets 3 and a number of water outlets 4 communicating with the cavity of the probe housing (1, 2); and

[0068] A circulating cooling channel formed by the cavity between the probe shell (1, 2) and the permanent magnet group (7, 8), the exciting / receiving coil 10, and the hollow tube 5.

[0069] ...

Embodiment 2

[0082] Such as Figure 7 to Figure 10 As shown, this embodiment provides an online rapid detection method using the ultra-high temperature casting and forging to detect the electromagnetic ultrasonic probe, including:

[0083] Pass cooling water into the water inlet and the upper end of the hollow pipe, and control the flow;

[0084]A low-frequency, high-power Chirp linear frequency modulation pulse current is passed into the excitation / reception coil, thereby exciting a beam of sinusoidal sweeping transverse wave ultrasound, which propagates along the thickness direction of the tested sample;

[0085] The excitation / receiving coil receives the electrical signal converted from the ultrasonic echo. After amplification and filtering, the signal corresponding to the Chirp linear frequency modulation pulse current frequency segment is obtained, which is converted into a digital signal and transmitted to the PC. After pulse compression processing, a real-time A Scan to display the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com