Single crystal wafer cleaning method

A single-chip, wafer technology, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of particle pollution, poor wettability, adsorption, etc., to reduce adsorption, improve wettability, and reduce particle pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

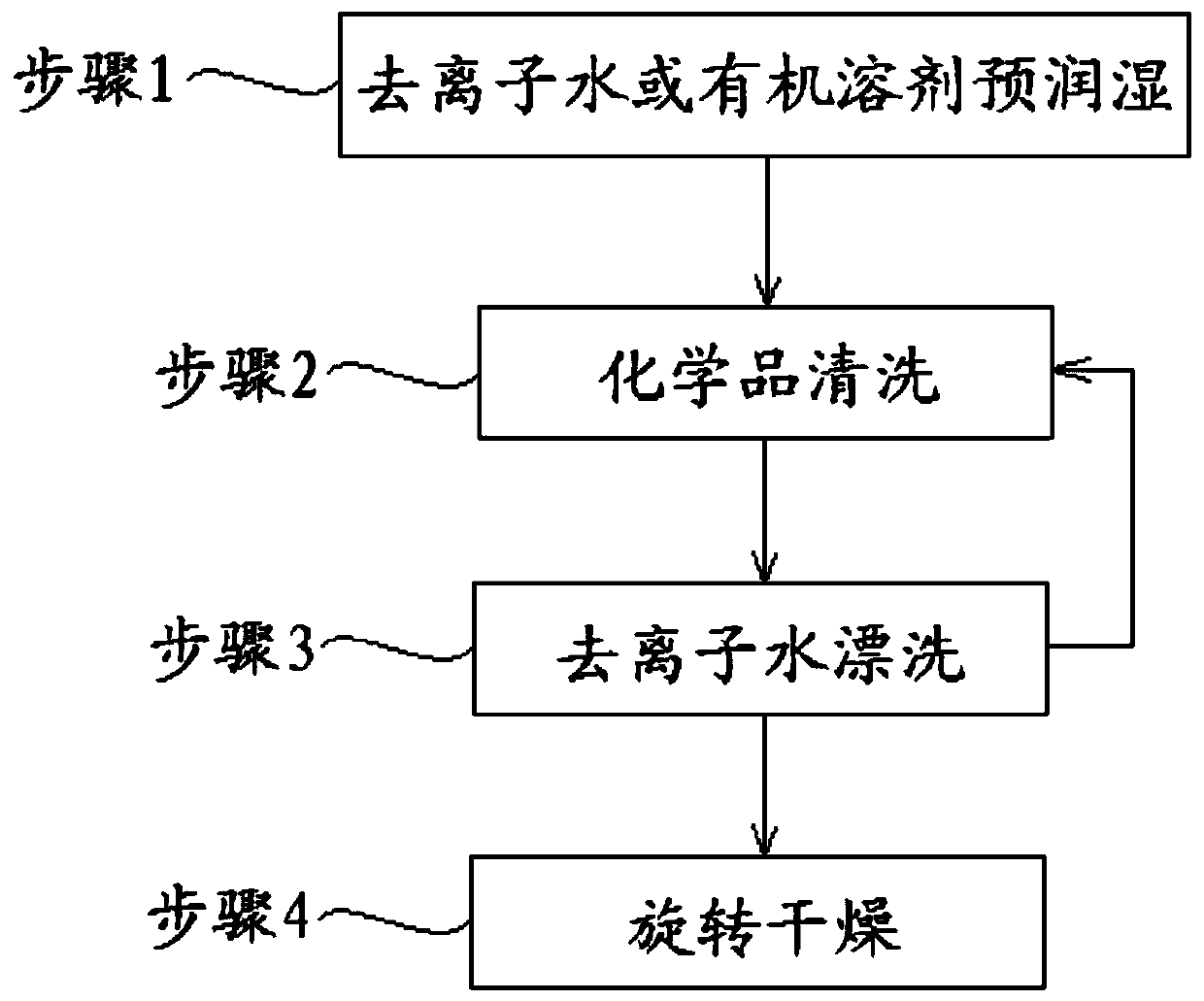

[0034] As a preferred embodiment of the present invention, the wafer to be cleaned is fixed on a rotating chuck, and the wafer is rotated synchronously with the chuck, and undergoes the following cleaning steps (such as image 3 shown):

[0035] Step 1. Spray deionized water at room temperature from the deionized water nozzle to the surface of the rotating wafer to pre-wet the wafer surface, and the treatment time is A seconds;

[0036] Step 2. Spray a fluoride-containing cleaning solution from the cleaning solution nozzle to the surface of the rotating wafer to remove various pollutants such as particles, organic matter, and metal impurities; the temperature of the cleaning solution is B degrees Celsius, and the processing time is C seconds; Wherein, the cleaning solution used in this embodiment is not limited, for example, the cleaning solution may include ammonium fluoride, organic solvent and water;

[0037] Step 3, spray deionized water at normal temperature to the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com