Hardmask composition hardmask layer and method of forming patterns

A technology of hard mask layer and composition, which is applied in the direction of photolithography, coating, and photosensitive materials used in optomechanical equipment on the pattern surface, and can solve the problem that it is difficult to provide fine patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0152] Put 1,6-dihydroxypyrene (23 g, 0.1 mole), 1-hydroxypyrene-6-carbaldehyde (24 g, 0.1 mole) and p-toluene sulfonic acid (pTSA, 1 g) into In a 1-liter 2-neck round bottom flask equipped with a mechanical stirrer and a condenser, 112 g of propylene glycol monomethylether acetate (PGMEA) was added thereto, and the mixture was stirred at 110° C. for 12 hours to carry out the polymerization reaction. When the polymerization reaction was completed, water was added thereto to remove salt, and the reactant was concentrated with an evaporator. The concentrated reactant was diluted with 15% by weight of cyclohexanone based on the amount of the entire melt, and a solid generated by adding hexane thereto was filtered to obtain a polymer represented by Chemical Formula 1a.

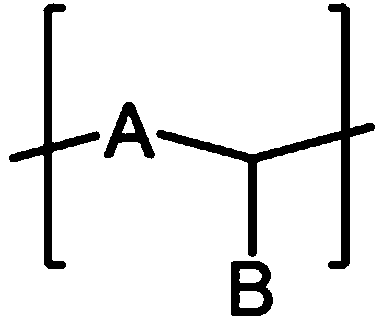

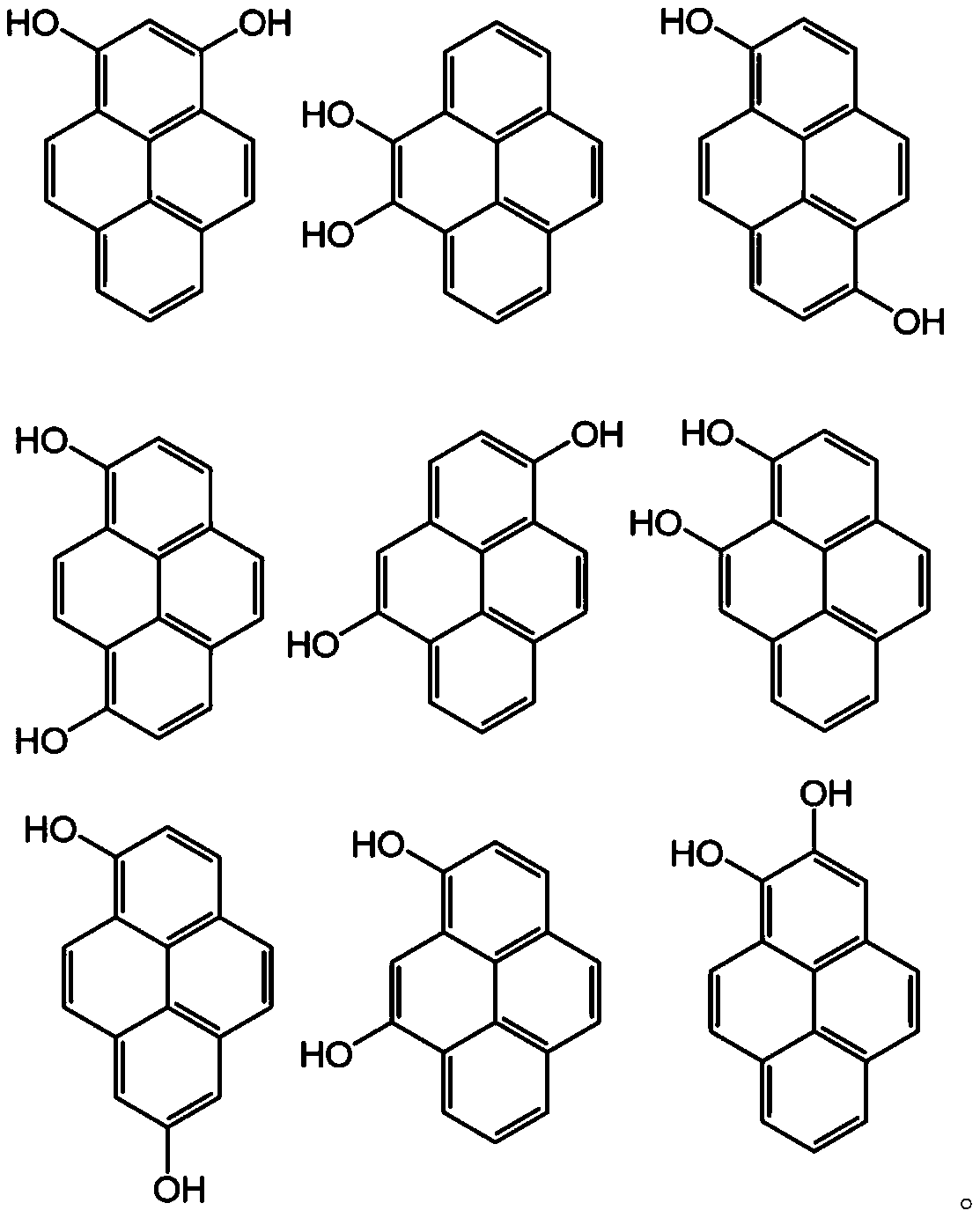

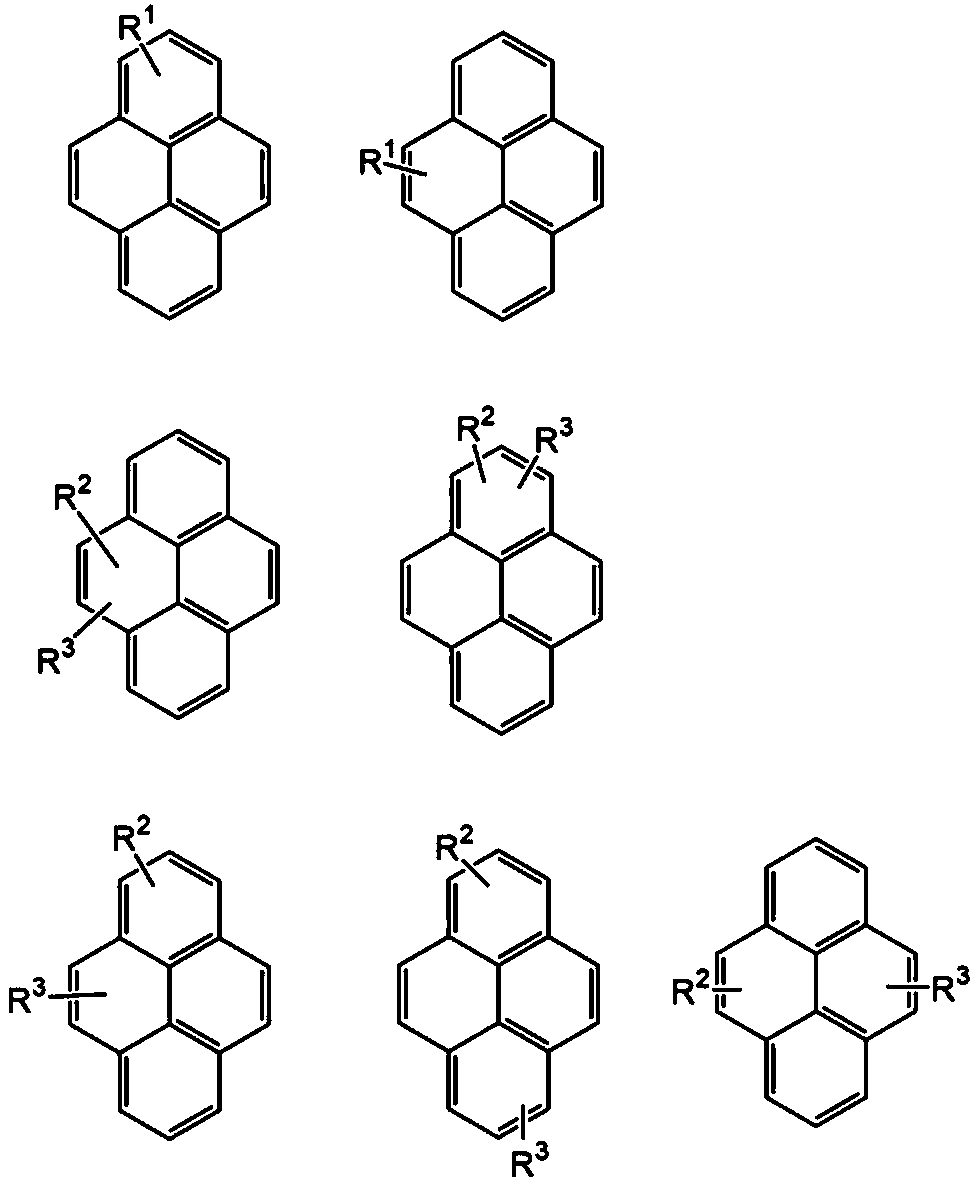

[0153] [chemical formula 1a]

[0154]

Synthetic example 2

[0156] A polymer represented by Chemical Formula 1b was prepared according to the same method as in Synthesis Example 1, except that pyreneformaldehyde (23 g, 0.1 mol) was used instead of 1-hydroxypyrene-6-carbaldehyde (24 g, 0.1 mol).

[0157] [chemical formula 1b]

[0158]

Synthetic example 1

[0160] Except that pyrene (20 g, 0.1 mol) was used instead of 1,6-dihydroxypyrene (23 g, 0.1 mol) and pyreneformaldehyde (23 g, 0.1 mol), the polymer represented by Chemical Formula A was prepared according to the same method as in Synthesis Example 1.

[0161] [chemical formula A]

[0162]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com