Device for recycling electrolyte of waste lithium ion battery at normal temperature

A lithium-ion battery, normal temperature recycling technology, applied in battery recycling, recycling technology, waste collector recycling and other directions, can solve the problems of fast volatilization, heavy electrolyte odor, harm to the health of production operators, etc., to improve recycling efficiency, The effect of efficient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is further described in conjunction with the following examples.

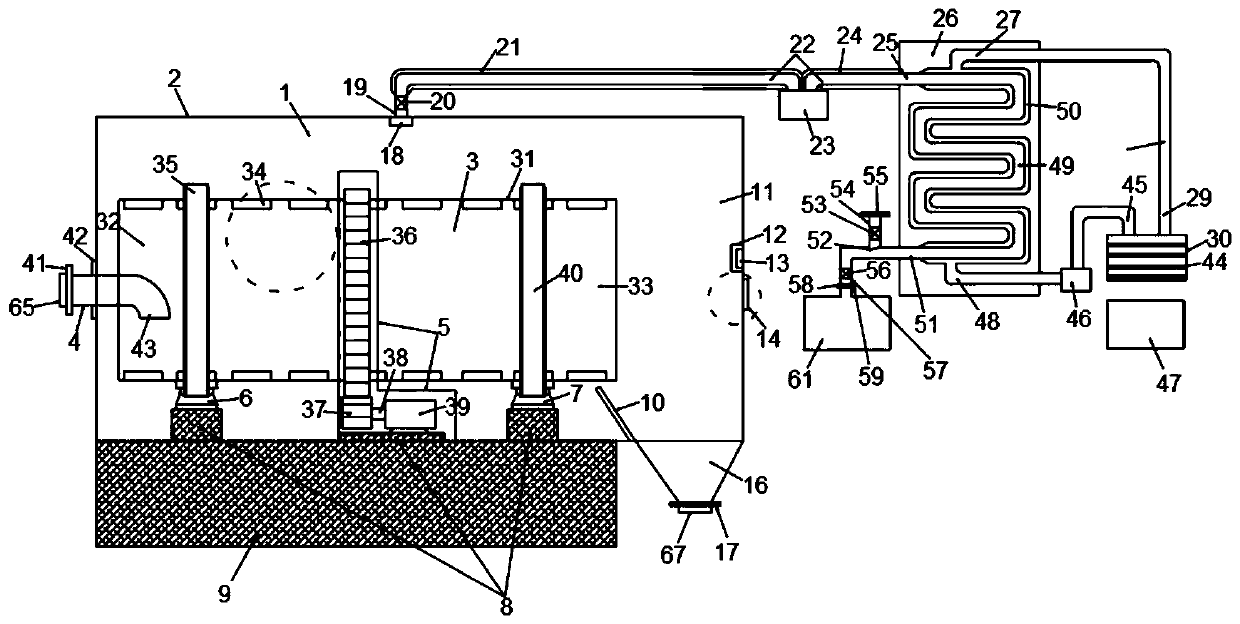

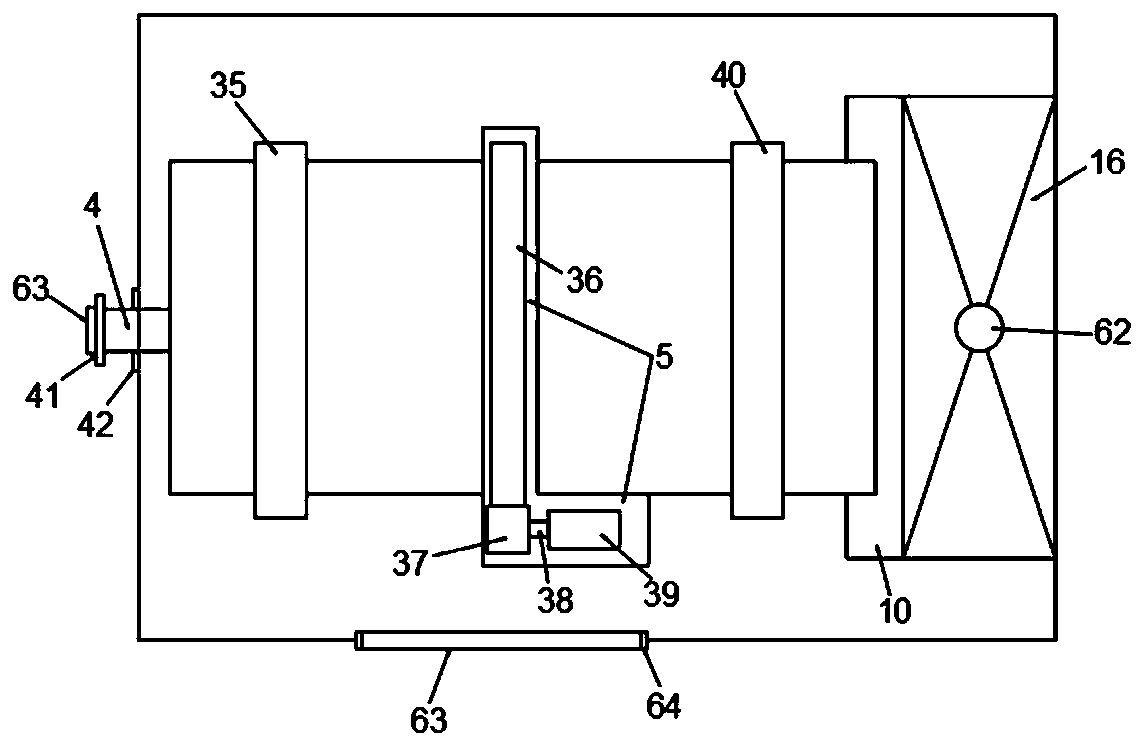

[0035] see Figure 1 to Figure 8, a device for recycling waste lithium-ion battery electrolyte at room temperature provided in this embodiment, the device includes a material inlet connector 4, a vacuum drying device 1, a condensation device, a nitrogen gas collection device, and an electrolyte collection box 61, and the material inlet connector The inlet end of 4 is sealed and connected to the discharge port of the equipment for conveying the waste lithium-ion battery crushed material crushed by nitrogen gas, and the discharge end 43 of the material inlet connection pipe 4 is sealed and connected to the vacuum drying equipment 1. The bottom of the vacuum drying equipment 1 is provided with a receiving hopper 16 for discharging waste lithium-ion battery crushed materials, the discharge port 62 of the receiving hopper 16 is provided with a second flange cover 67, and the top of the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com