High-performance die cast forming method and product based on two-plate die casting machine

A die-casting, high-performance technology, applied in the field of metal parts manufacturing and processing, can solve the problems of unsuitable two-plate die-casting machine, lack of die-casting process, etc., and achieve the effect of eliminating heat treatment defects, facilitating heat treatment, and stable mold filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] In this embodiment, an aluminum alloy automobile structural part of ADC12 grade is die-cast. A series of preparations are carried out before die casting, including equipment inspection of the two-plate die casting machine, mold preheating (preheating temperature is 200°C), spraying a layer of release agent on the surface of the die casting mold, aluminum alloy melting, and aluminum liquid transportation.

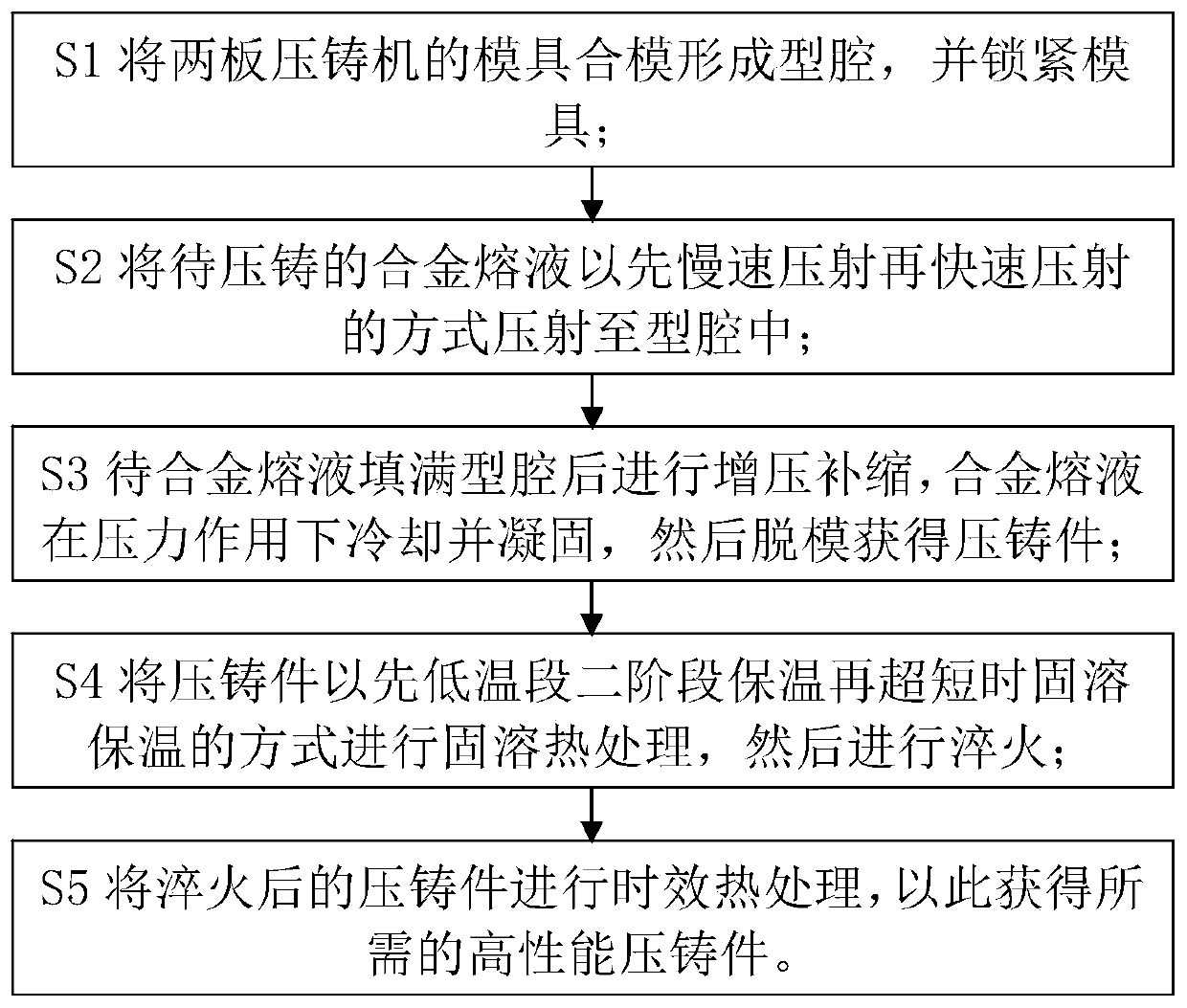

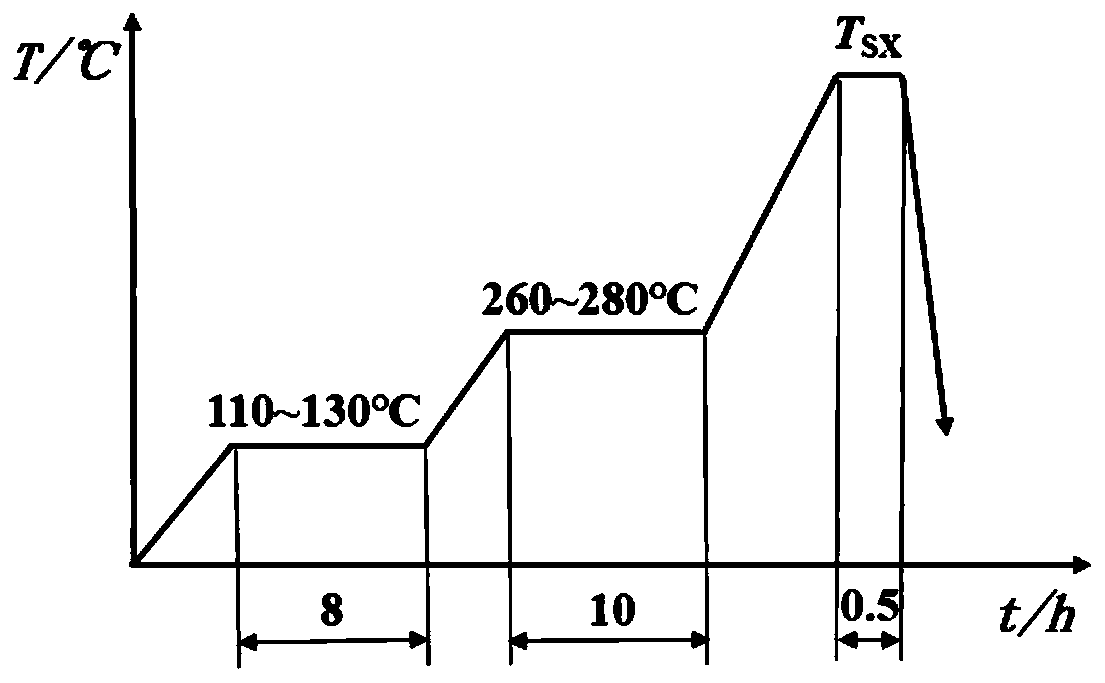

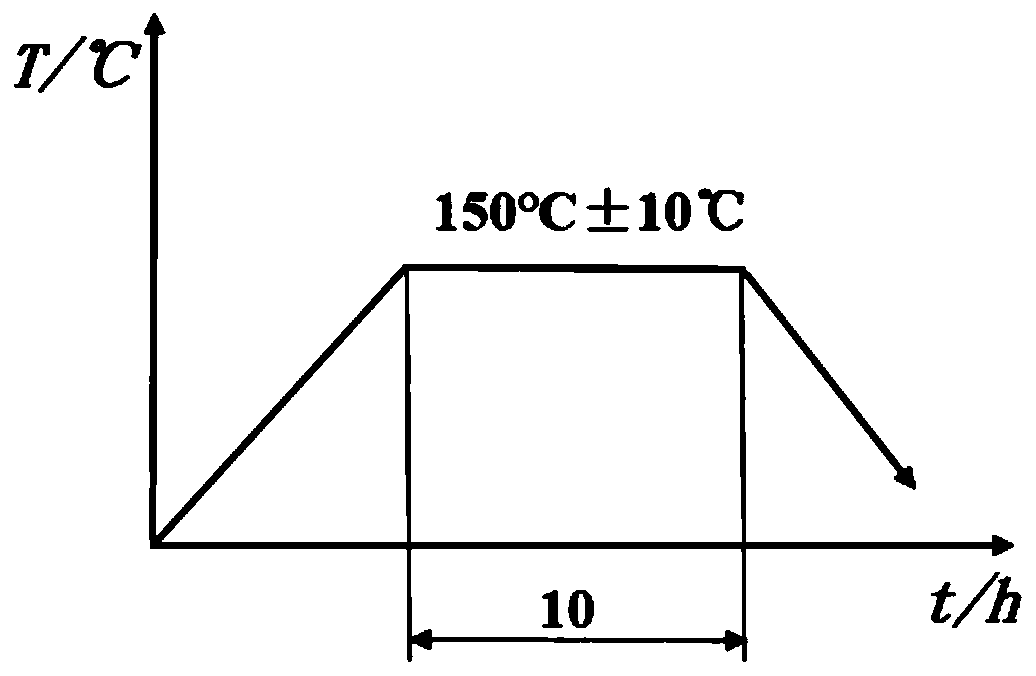

[0053] A die casting cycle and heat treatment process specifically includes the following steps:

[0054] Clamping and locking: the movable mold and the fixed mold are contacted and closed to form a cavity, and the mold is locked by the follow-up locking mechanism of the two-plate die-casting machine;

[0055] Pouring and injection: pour the 680 ℃ aluminum alloy melt into the barrel of the die casting machine, and then use the punch to inject the aluminum hydraulic pressure into the mold cavity that has been preheated to 200 ℃. The injection process is as follows: It...

Embodiment 2

[0061] In this embodiment, a YL112 aluminum alloy automobile structural part is die-cast. A series of preparations are carried out before die casting, including equipment inspection of the two-plate die casting machine, mold preheating (preheating temperature is 200°C), spraying a layer of release agent on the surface of the die casting mold, aluminum alloy melting, and aluminum liquid transportation.

[0062] A die casting cycle and heat treatment process specifically includes the following steps:

[0063] Clamping and locking: contact the movable mold with the fixed mold, close the mold to form a cavity, and use the follow-up locking mechanism of the two-plate die-casting machine to lock the mold;

[0064] Pouring and injection: pour the aluminum alloy melt at 680°C into the barrel of the die-casting machine, and then use the injection punch to hydraulically inject the aluminum into the mold cavity that has been preheated to 200°C. The injection process is specific In order...

Embodiment 3

[0070]In this embodiment, an aluminum alloy automobile structural part of ADC6 grade is die-cast. A series of preparations are carried out before die casting, including equipment inspection of the two-plate die casting machine, mold preheating (preheating temperature is 200°C), spraying a layer of release agent on the surface of the die casting mold, aluminum alloy melting, and aluminum liquid transportation.

[0071] A die casting cycle and heat treatment process specifically includes the following steps:

[0072] Clamping and locking: the movable mold and the fixed mold are contacted and closed to form a cavity, and the mold is locked by the follow-up locking mechanism of the two-plate die-casting machine;

[0073] Pouring and injection: pour the aluminum alloy melt at 680°C into the barrel of the die-casting machine, and then use the injection punch to hydraulically inject the aluminum into the mold cavity that has been preheated to 200°C. The injection process is specific ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com