Multi-blade type electrode cap grinding knife rest

A technology of electrode cap and sharpening holder, applied in the direction of electrode characteristics and electrode maintenance, can solve the problems of difficult to guarantee welding strength, inconvenient replacement, uneven cutting force, etc., to overcome uneven cutting force and facilitate replacement and installation. , Improve the effect of grinding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

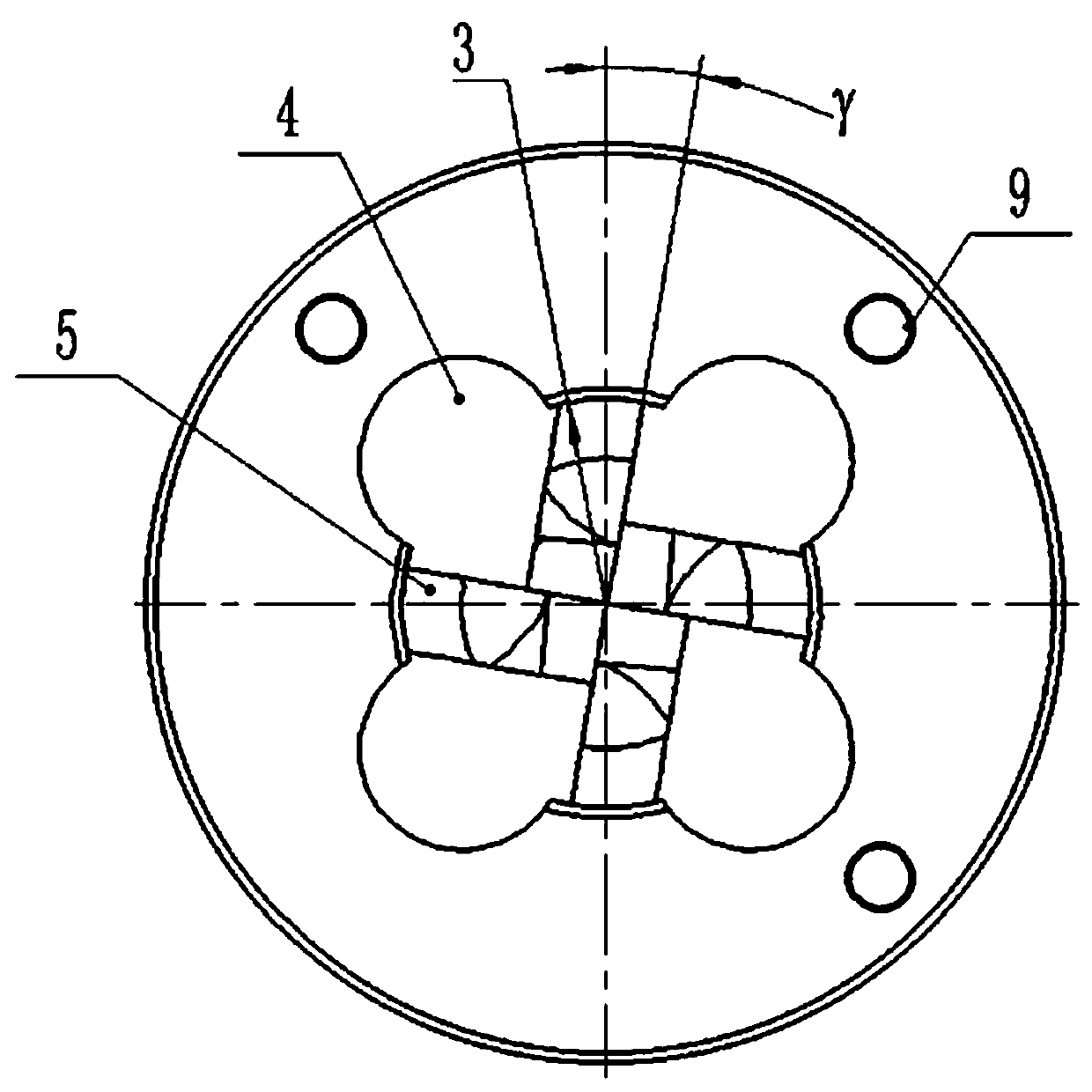

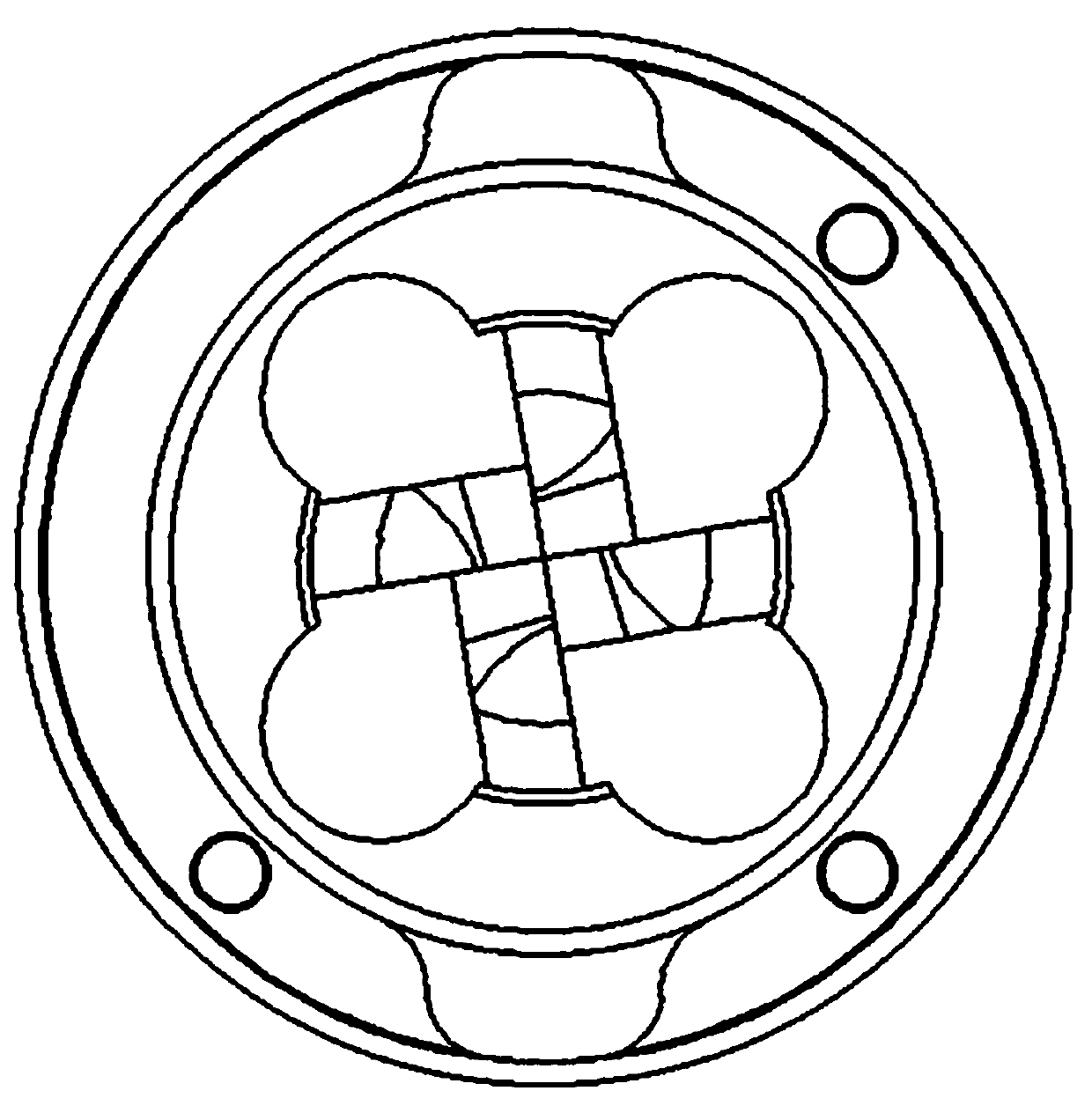

[0044] Such as Figure 1-4 It can be seen that two lock lugs 2 are provided at the small-diameter shaft extension of the solid stepped shaft 1, and a base circle 3 that is concentric with the center of the solid stepped shaft 1 is set inside the solid stepped shaft 1 based on the center of the solid stepped shaft 1, and On the base circle 3, the chip removal holes 4 are uniformly distributed outwards to the inside of the solid stepped shaft 1, and the cutter body 5 is uniformly distributed on the contour line of the base circle 3, and the main cutting edge 6 of the cutter body 5 is respectively connected to the solid stepped shaft 1. The centerline of the center line forms an included angle γ, and on the cutter body 5 respectively forms a rake angle 7 of an included angle β and derives a secondary cutting edge 8 along the shape of the main cutting edge 5 .

[0045] Further, the value of the γ included angle is in the range of 10°-20°.

[0046] Further, the value of the β incl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com