AGV carrying robot for copper foil reel conveying

A technology for handling robots and copper foil rolls, applied in motor vehicles, transportation and packaging, lifting devices, etc., can solve the problems of unable to keep up with the production rhythm of raw foil machines, unable to obtain raw materials in time, physical health injuries, etc. Dangerous and labor-intensive, wide practical range, high safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

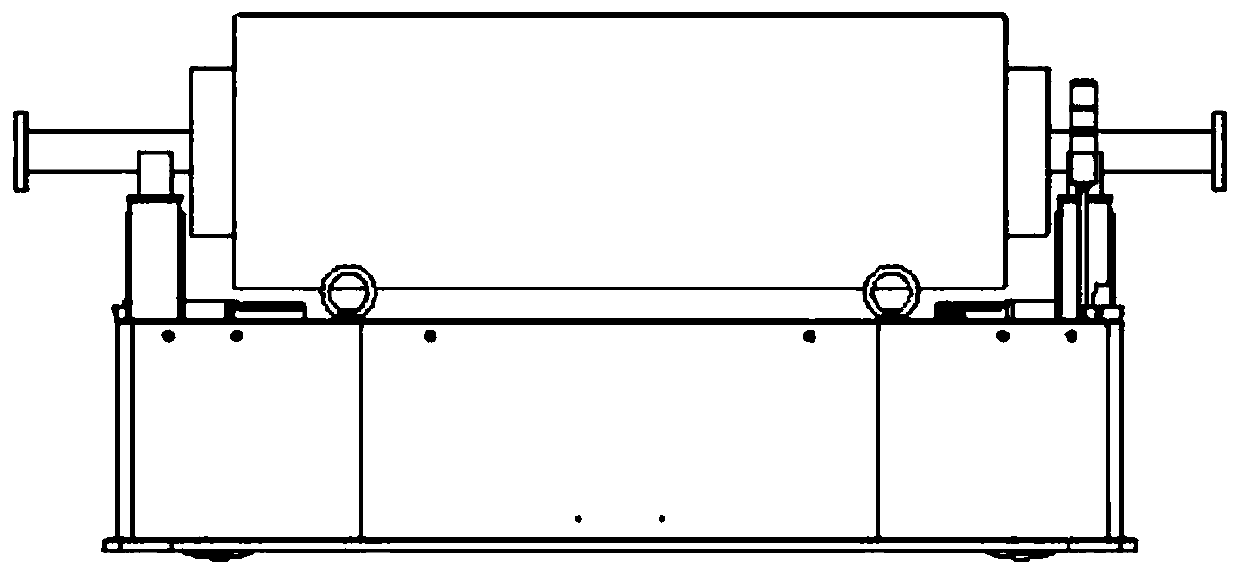

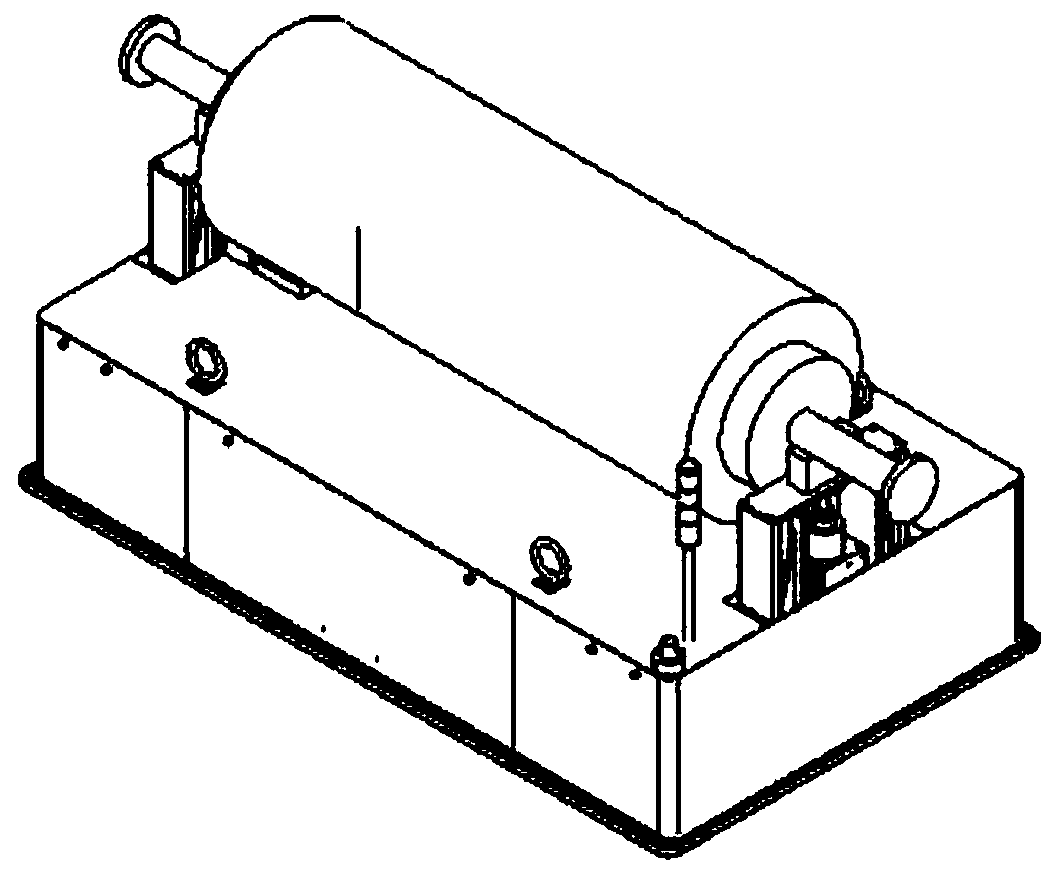

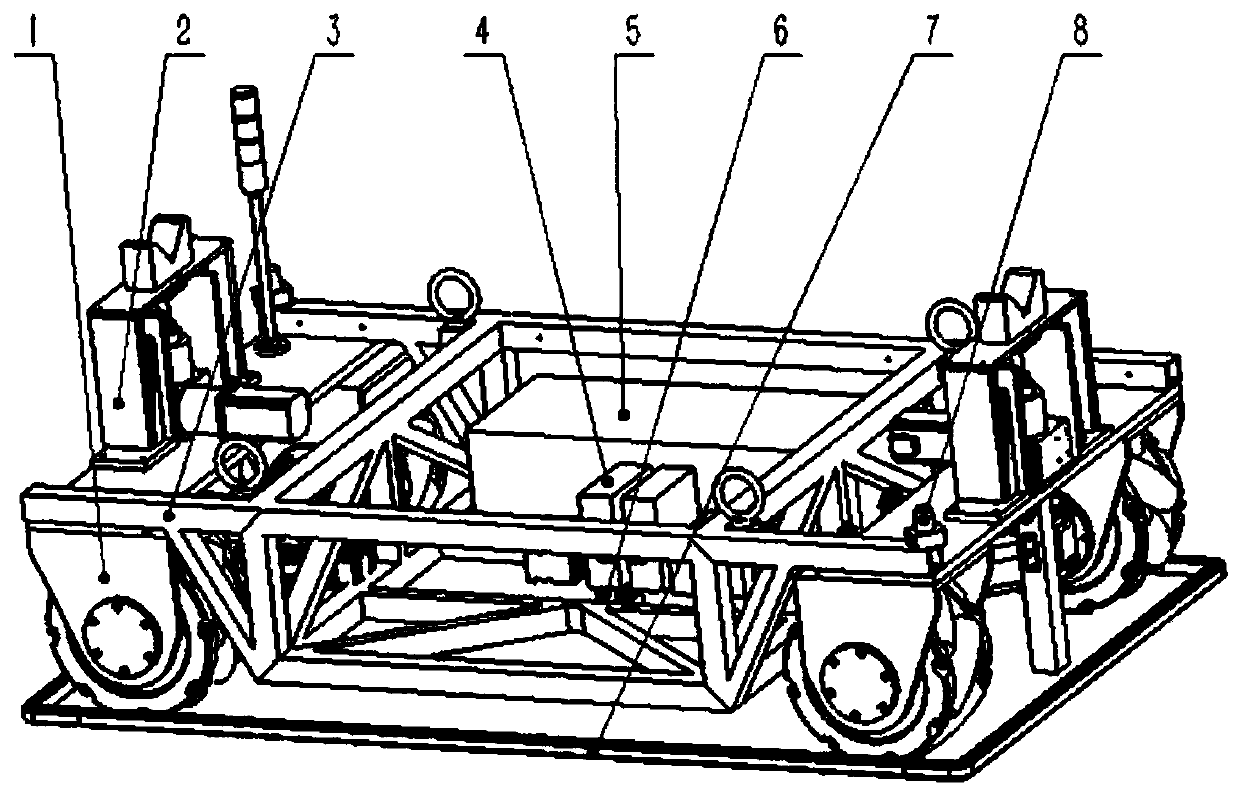

[0026] The present invention is an AGV handling robot for copper foil reel delivery, the structure of which is shown in Figure 1- image 3 As shown, the chassis structure 3 is included, and the bottom of the chassis structure 3 is provided with a visual navigation sensor 6. The front and rear positions of the chassis structure 3 are respectively provided with a wheel drive system 1, and each wheel drive system 1 is provided with a lifting system 2. The chassis structure 3 is also provided with a controller 4 inside, and the controller 4 controls the operation of the wheel drive system 1 and the lifting system 2.

[0027] The specific structure of the chassis structure 3 is: including a vehicle frame 12, the bottom of the vehicle frame 12 is covered with a bottom skin 13, the front of the vehicle frame 12 is covered with a front skin 9, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com