Preparation method of fully-closed pore porous mullite ceramic based on direct solidification injection molding

A technology of porous mullite and injection molding, which is applied in the direction of ceramic products, ceramic material production, clay products, etc., can solve the problems of long preparation period and difficulty in obtaining porous ceramics with fully closed-pore structure, so as to ensure excellent performance, Low equipment requirements and good combination performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

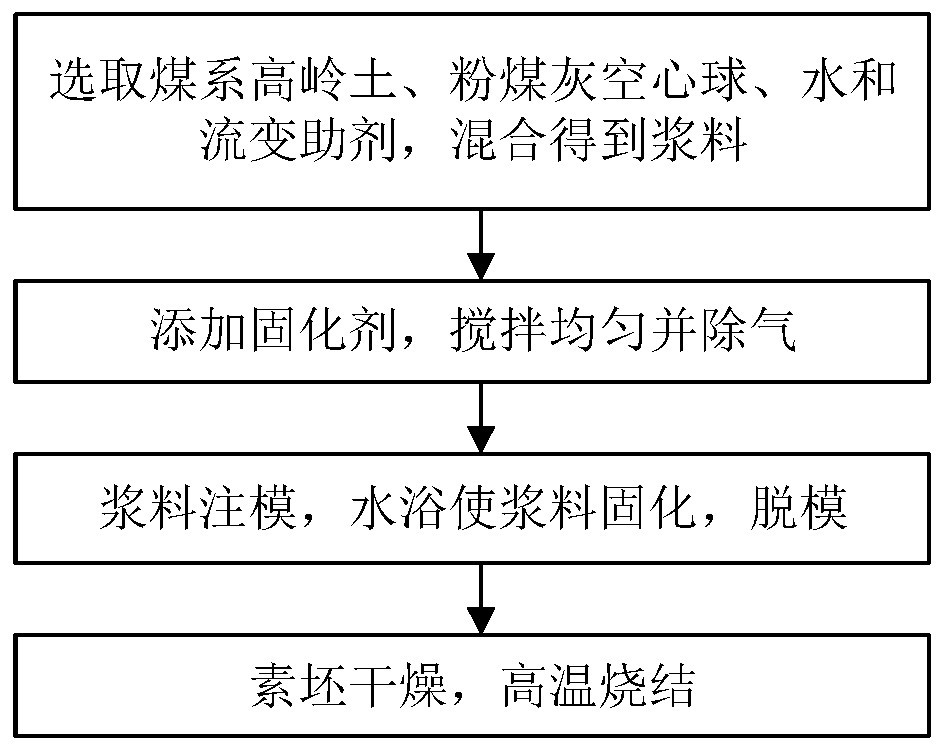

[0026] Such as figure 1 As shown, the present invention provides a kind of fully closed cell porous mullite ceramics preparation method based on direct solidification injection molding, and the method comprises the following steps:

[0027] S1 Mix kaolin powder, fly ash hollow balls, deionized water and rheological additives, and use high-speed shearing or mechanical stirring to prepare a uniformly dispersed ceramic slurry;

[0028] S2 Add a curing agent to the ceramic slurry and mix it evenly, then degas it by vacuum degassing or centrifugal degassing to obtain a mixed slurry;

[0029] S3 inject the mixed slurry into the mold, and then heat it in a water bath at 50°C to 90°C for 0.5h to 2h to solidify it, and obtain a ceramic green body after demoulding;

[0030] S4 Dry the ceramic green body at a temperature of 50°C to 90°C for 12h to 24h, and finally place the dried ceramic green body in a sintering furnace, and sinter it at a temperature of 1350°C to 1600°C for 1h to 2h. ...

Embodiment 1

[0037] S1 Mix 45g of coal-based kaolin powder, 15g of fly ash hollow balls and 40g of deionized water, and use high-speed shearing to prepare a ceramic slurry with a solid phase content of 60wt%. The particle size of the fly ash hollow balls is 90μm;

[0038] S2 Add calcium iodate at a ratio of 8g / L to the ceramic slurry and mix evenly, then use vacuum degassing to degas it to obtain a mixed slurry;

[0039] S3 injecting the mixed slurry into a silica gel mold, keeping the temperature in a water bath at 70°C for 1 hour to solidify the mixed slurry, and obtaining a ceramic green body after demoulding;

[0040]S4 Dry the ceramic green body at 90° C. for 12 hours, and sinter it at 1550° C. for 1 hour to prepare fully closed-pore porous mullite ceramics.

Embodiment 2

[0042] S1 Mix 20g of coal-based kaolin powder, 50g of fly ash hollow balls, 30g of deionized water and 0.3g of cellulose, and use mechanical stirring to prepare a ceramic slurry with a solid phase content of 70wt%, wherein the fly ash hollow The particle size of the ball is 20μm;

[0043] S2 Add barium iodate in the proportion of 6g / L to the ceramic slurry and mix evenly, then degas it by vacuum degassing to obtain the mixed slurry;

[0044] S3 inject the mixed slurry into the silica gel mold, keep warm for 0.5h in a water bath at 90°C to solidify the mixed slurry, and obtain a ceramic green body after demoulding;

[0045] S4 The ceramic green body was dried at 65° C. for 20 hours, and sintered at 1350° C. for 2 hours to prepare fully closed-pore porous mullite ceramics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com