A kind of resin underwater curing agent and preparation method thereof

A technology of underwater curing and amine curing agent, which is applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of low curing efficiency and reduced mechanical properties of materials, and achieve the effect of high curing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The resin underwater curing agent is composed of triethylenetetramine, maleic anhydride and triethylamine; by weight percentage triethylenetetramine: maleic anhydride: triethylamine is 70%: 28 %:2%.

[0027] The underwater curing agent is applied to epoxy resin, and the viscosity value of epoxy resin glue in this system is 1800mPa. s, the underwater curing agent has a viscosity value of 500mPa at 25°C. s. The epoxy resin underwater curing agent and epoxy resin are mixed evenly at a mass ratio of 20:100 at 30°C at a stirring rate of 300r / min for 30min, vacuum pumped air bubbles at 30°C, placed in a 60°C water environment, 30°C Fully cured in minutes. The formed cured material has a compressive strength of up to 70MPa and a temperature resistance of up to 180°C.

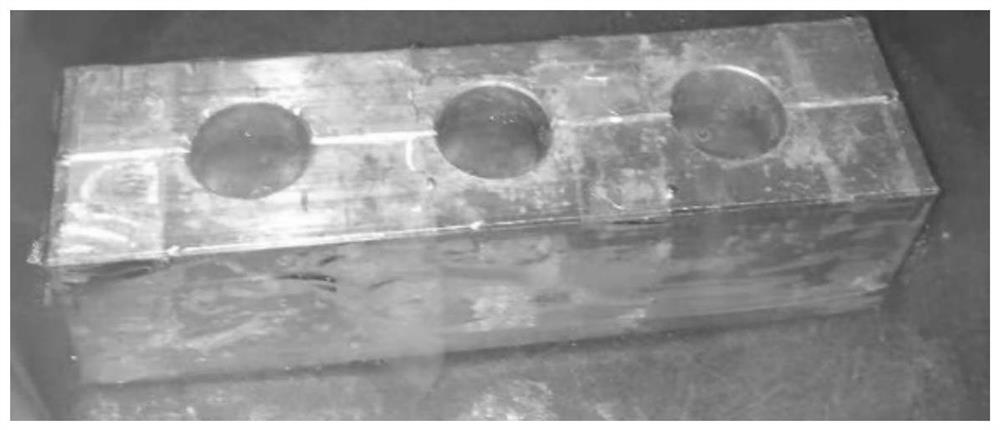

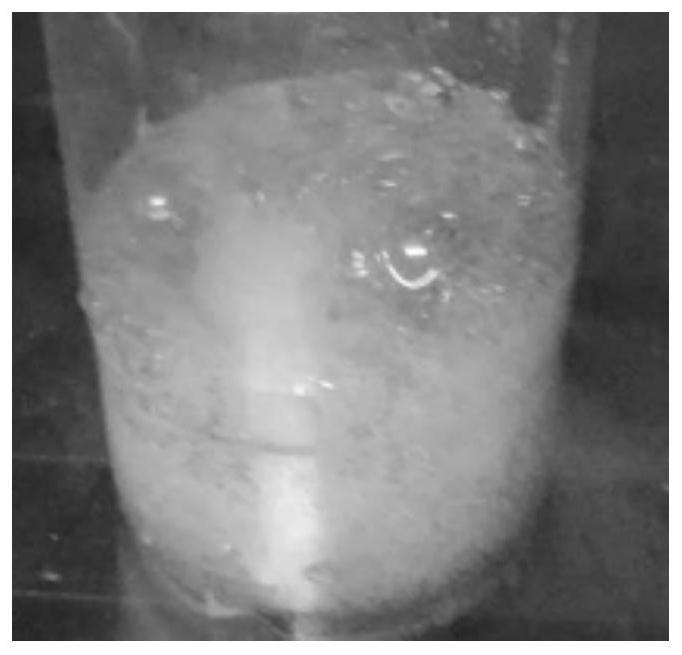

[0028] Depend on figure 1 It can be seen that the compatibility and compatibility between the underwater curing agent and epoxy resin are excellent, and there is no need to heat up during the mixing process...

Embodiment 2

[0033] The resin underwater curing agent is compounded by m-phenylenediamine, hexahydrophthalic anhydride and triethylamine; by weight percentage, m-phenylenediamine: hexahydrophthalic anhydride: triethylamine is 75%: 20 %: 5%.

[0034] The underwater curing agent is applied to polyurethane resin, and the viscosity value of polyurethane resin glue in this system is 2000mPa. s, the viscosity value of the underwater curing agent at 25°C is 1500mPa. s. Stir the polyurethane resin underwater curing agent and polyurethane resin at a mass ratio of 30:100 at 30°C at a stirring rate of 200r / min for 50 minutes to mix evenly, vacuum air bubbles at 30°C, place in a water environment of 50°C, and set to 30 minutes. Can be fully cured. The formed cured material has a compressive strength of up to 70MPa and a temperature resistance of up to 220°C.

Embodiment 3

[0036] The resin underwater curing agent is compounded by diaminodiphenylmethane, glutaric anhydride and triethylamine; by weight percentage, diaminodiphenylmethane: glutaric anhydride: triethylamine is 60%: 35%: 5%.

[0037] The underwater curing agent is applied to phenolic resin, and the viscosity value of the phenolic resin glue in this system is 9000-12000mPa. s, the viscosity value of the underwater curing agent at 25°C is 1500mPa. s. The phenolic resin underwater curing agent and phenolic resin are mixed at a mass ratio of 10:100 at a stirring rate of 400r / min for 60 minutes at 30°C and mixed evenly, vacuum pumped air at 30°C, and placed in a water environment of 40°C for 30 minutes. Can be fully cured. The formed cured material has a compressive strength of up to 56MPa and a temperature resistance of up to 180°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com