A kind of inkjet bleed ceramic color enhancement ink and using method thereof

A technology of ink and flower bleeding, applied in the direction of ink, application, household utensils, etc., can solve the problems of uneven dispersion, agglomeration, poor fluidity, etc., and achieve the effect of stable color development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A method for preparing and using an inkjet bleeding ceramic color-enhancing ink, comprising the following steps:

[0047] Step 1. In terms of mass percentage, 75% ethyl orthosilicate, 8% absolute ethanol, 8% diethylene glycol dibutyl ether solvent, 8% diethylene glycol butyl ether acetate, tension regulator AK- 505 0.6% and defoamer Foamex-810 0.4% were mixed to prepare inkjet bleeding ceramic color enhancement ink A. The viscosity of the above ink A is 24~26cp, and the surface tension is 25~27mN / m. The printing temperature of the ink A is 46°C.

[0048] Step 2. In mass percentage, ammoniacal liquor 35%, distilled water 40%, absolute ethanol 5%, ethylene glycol monoethyl ether 8%, dipropylene glycol methyl ether acetate 10%, calcium chloride 1%, tension regulator AK -505 0.8% and defoamer Foamex-810 0.2% are mixed to prepare inkjet bleeding ceramic color enhancement ink B. The above-mentioned ink B has a viscosity of 23~25cp, and a surface tension of 21~23mN / m. The ...

Embodiment 2

[0053] A method for preparing and using an inkjet bleed ceramic color-enhancing ink, comprising the following steps:

[0054] Step 1. In terms of mass percentage, 77% ethyl orthosilicate, 7% absolute ethanol, hexadecane C 16 h 34 7%, dipropylene glycol methyl ether acetate 8%, tension regulator BYK306 0.8%, defoamer BYK055 0.2%, and the inkjet bleed ceramic color enhancement ink A was prepared. The viscosity of the above ink A is 23-25cp, and the surface tension is 26-28mN / m. The printing temperature of the ink A is 46°C.

[0055] Step 2. In terms of mass percentage, mix ammonia 32%, distilled water 42%, absolute ethanol 6%, hexadecane C16H34 9%, dipropylene glycol methyl ether acetate 9%, sodium fluoride 1.2%, tension regulator BYK306 0.6 %, antifoaming agent BYK055 0.2% mixed to prepare inkjet bleed ceramic color enhancement ink B. The viscosity of the ink B is 22-24cp, and the surface tension is 23-25mN / m. The printing temperature of the ink B is 46°C.

[0056] Step ...

Embodiment 3

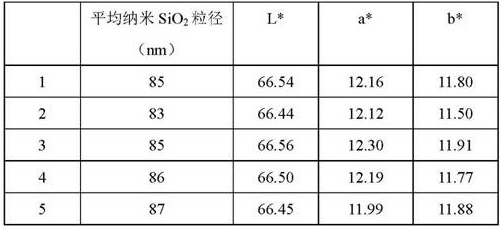

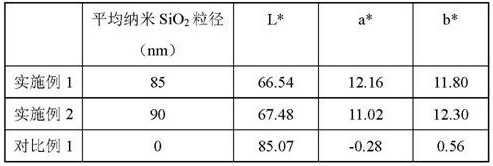

[0068] The color development repeatability stability of the inkjet bleeding ceramic color-enhancing ink of Example 1 was tested. Repeat embodiment 1 totally 5 times, and record LAB value.

[0069] Table 2 Color development performance test table

[0070]

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com