Vacuum sealing lubricating grease and preparation method thereof

A vacuum sealing and grease technology, applied in the field of silicone grease, can solve problems such as poor sealing performance, grease loss, gas leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

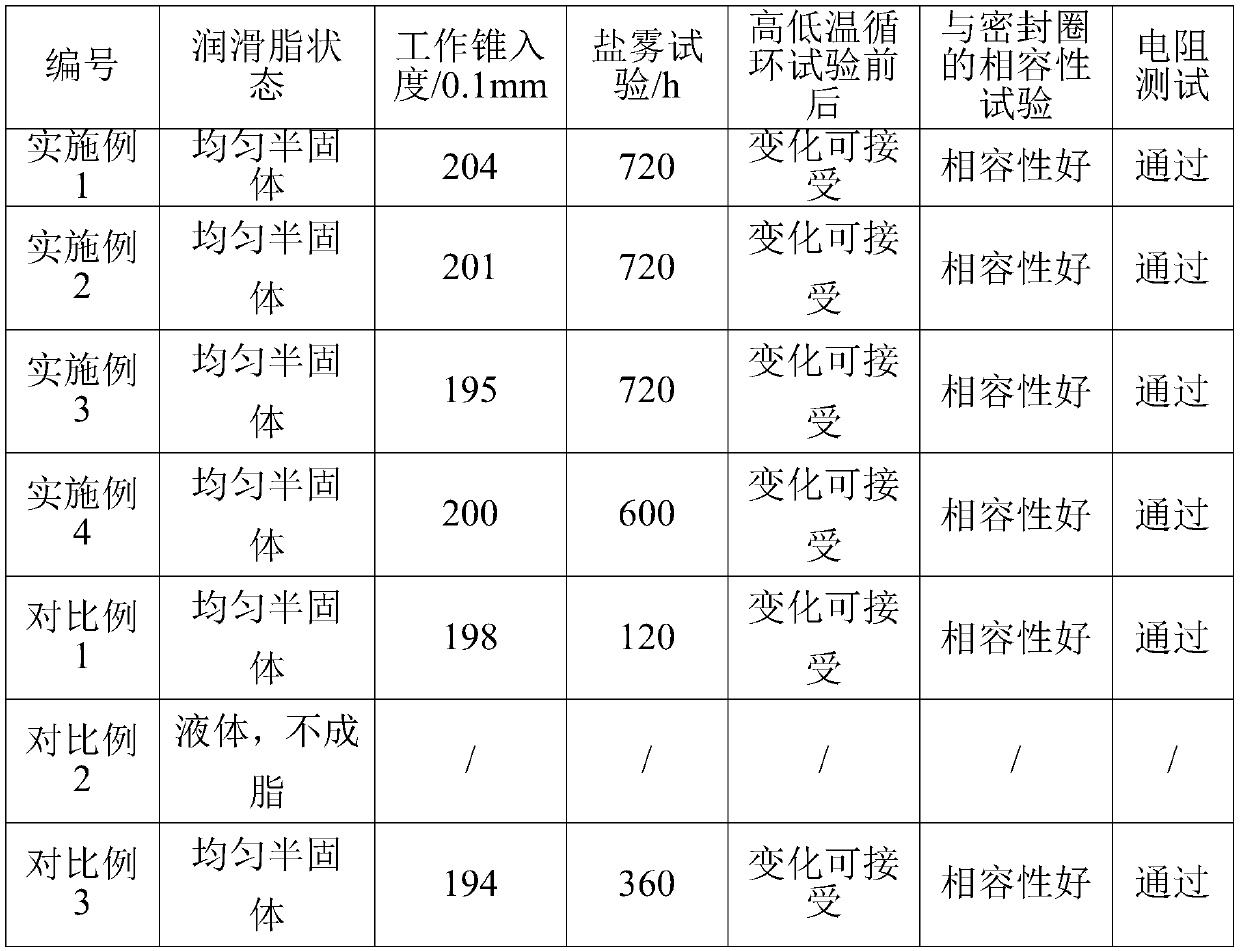

Examples

Embodiment 1

[0045] Prepare a kind of vacuum sealing grease through the following steps, and conduct a performance test:

[0046] (1) 784.8g methyl silicone oil (chemical formula is (CH 3 ) 3 SiO[(CH 3 ) 2 SiO] n Si(CH 3 ) 3 , where n=600~700; the viscosity at 25°C is 5000mm 2 / s), 42.4g of crystalline diphenyldihydroxysilane and absolute ethanol were added to the reaction kettle, heated to 40°C, and kept at a constant temperature for 30min;

[0047] (2) After the constant temperature is over, heat to 90°C, add an aqueous emulsion containing 67.8g of magnesium carbonate to the reactor, and keep the temperature constant for 120min; during the process of adding magnesium carbonate and constant temperature, vacuum inhale 105g of fumed silica;

[0048] (3) After the constant temperature is completed, heat to 130°C and keep the temperature constant for 30 minutes;

[0049] Above steps (1)~(3) all carry out under stirring;

[0050] (4) After the constant temperature is finished, grind i...

Embodiment 2

[0058] Prepare a kind of vacuum sealing grease through the following steps, and conduct a performance test:

[0059] (1) 796g methyl silicone oil (chemical formula is (CH 3 ) 3 SiO[(CH 3 ) 2 SiO] n Si(CH 3 ) 3 , where n=800~900; the viscosity at 25°C is 10000mm 2 / s), 38g of crystalline diphenyldihydroxysilane and absolute ethanol were added to the reaction kettle, heated to 80°C, and kept at a constant temperature for 30min;

[0060] (2) After the constant temperature is over, heat to 85°C, add an aqueous emulsion containing 60.8g basic magnesium carbonate to the reaction kettle, and keep the temperature constant for 120min; during the process of adding basic magnesium carbonate and constant temperature, vacuum inhale 100g fumed silica ;

[0061] (3) After the constant temperature is completed, heat to 150°C and keep the temperature constant for 30 minutes;

[0062] Above steps (1)~(3) all carry out under stirring;

[0063] (4) After the constant temperature is fini...

Embodiment 3

[0071] Prepare a kind of vacuum sealing grease through the following steps, and conduct a performance test:

[0072] (1) 806.2g methyl silicone oil (chemical formula is (CH 3 ) 3 SiO[(CH 3 ) 2 SiO] n Si(CH 3 ) 3 , where n=1200~1300; the viscosity at 25°C is 30000mm 2 / s), 40g of crystalline diphenyldihydroxysilane and absolute ethanol were added to the reaction kettle, heated to 60°C, and kept at a constant temperature for 30min;

[0073] (2) After the constant temperature is over, heat to 95°C, add an aqueous emulsion containing 64g of barium carbonate to the reactor, and keep the temperature constant for 120min; during the process of adding barium carbonate and constant temperature, vacuum inhale 95g of fumed silica;

[0074] (3) After the constant temperature is completed, heat to 140°C and keep the temperature constant for 30 minutes;

[0075] Above steps (1)~(3) all carry out under stirring;

[0076] (4) After the constant temperature is finished, grind in a three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com