An air treatment device in the production process of carbon fiber precursor and its application

An air treatment device and carbon fiber precursor technology, which is applied in the field of chemical fiber production, can solve the problems of fiber strength and quality, increase filament winding and broken filament, and affect oiling effect, so as to avoid local overheating, reduce replacement frequency, and reduce The effect of oil consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

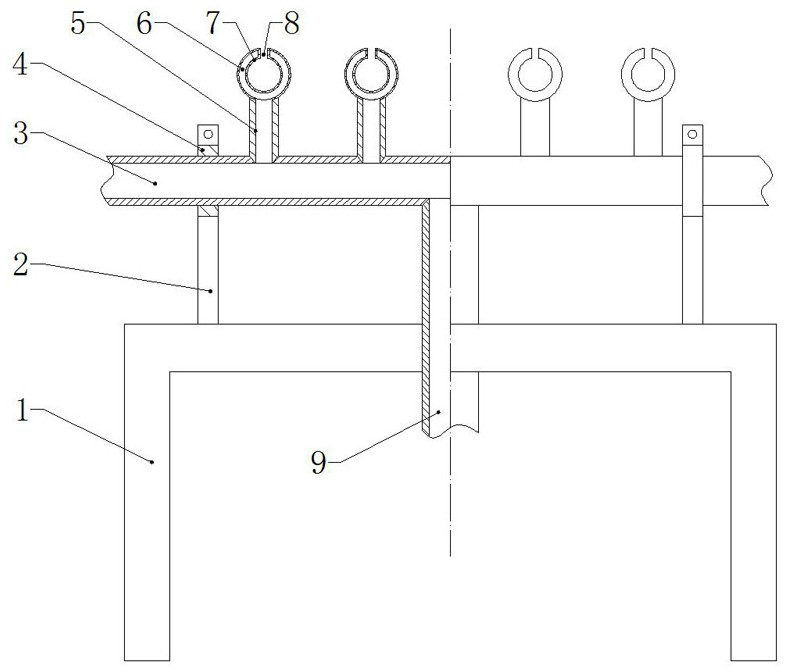

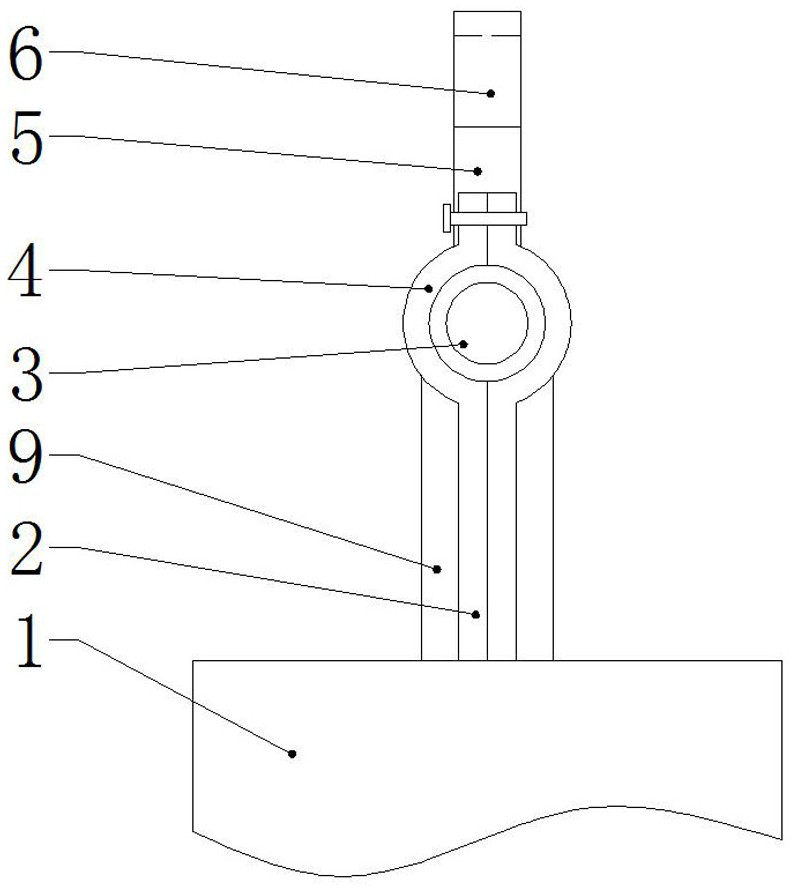

[0024] Such as Figure 1 to Figure 3 As shown, the air treatment device provided in Example 1 is applied to wet spinning of polyacrylonitrile-based carbon fiber precursors.

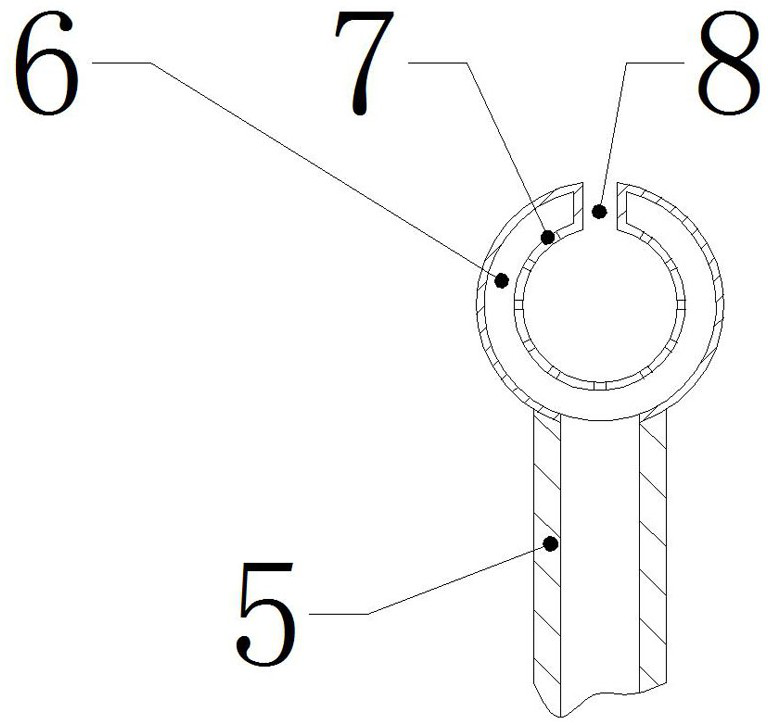

[0025] Tighten the lower end of the gas transmission branch pipe 5 with raw material tape, and then connect it to the corresponding threaded port of the gas transmission main pipe 3. The gas transmission main pipe 3 is fixed on the workbench 1 through the bracket 2 and the collar 4. The diameter of the gas transmission main pipe 3 is 20mm , the lower part of the gas delivery main pipe 3 is connected to the intake pipe 9, and the ports at both ends of the gas delivery main pipe 3 are closed. The inner diameter of the air blowing ring 6 is 10 mm, the outer diameter is 15 mm, and eight air injection ports 7 are evenly distributed around the inner circle, and the aperture of the air injection ports 7 is 1 mm. The upper end of the blowing ring 6 is provided with a diversion notch 8, the width of the diversion...

Embodiment 2

[0029] Such as Figure 1 to Figure 3 As shown, the air treatment device provided in Example 2 is applied to dry-jet wet spinning of polyacrylonitrile-based carbon fiber precursors.

[0030] The gas delivery branch pipe 5, the gas delivery main pipe 3 and the blowing ring 6 are integrally formed. The gas delivery main pipe 3 is fixed on the workbench 1 through the bracket 2 and the collar 4. The diameter of the gas delivery main pipe 3 is 25 mm. Connect the inlet pipe 9, and the two ends ports of the gas delivery main pipe 3 are closed. The inner diameter of the air blowing ring 6 is 15 mm, the outer diameter is 20 mm, and 10 air jets 7 are evenly distributed around the inner circle, and the diameter of the air jets 7 is 1 mm. The upper end of the blowing ring 6 is provided with a diversion gap 8, the width of the diversion gap 8 is 4mm, and the lower side of the blowing ring 6 is connected to the gas delivery branch pipe 5, and the diameter of the gas delivery branch pipe 5 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com