Insect-proof and radiation-proof fabric and preparation process thereof

A preparation process and radiation protection technology, applied in the field of textile materials, can solve the problems of poor air permeability and insignificant protection effect of radiation protection fabrics, and achieve the effects of long-lasting insect repellent performance, rapid construction and pleasant mood.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

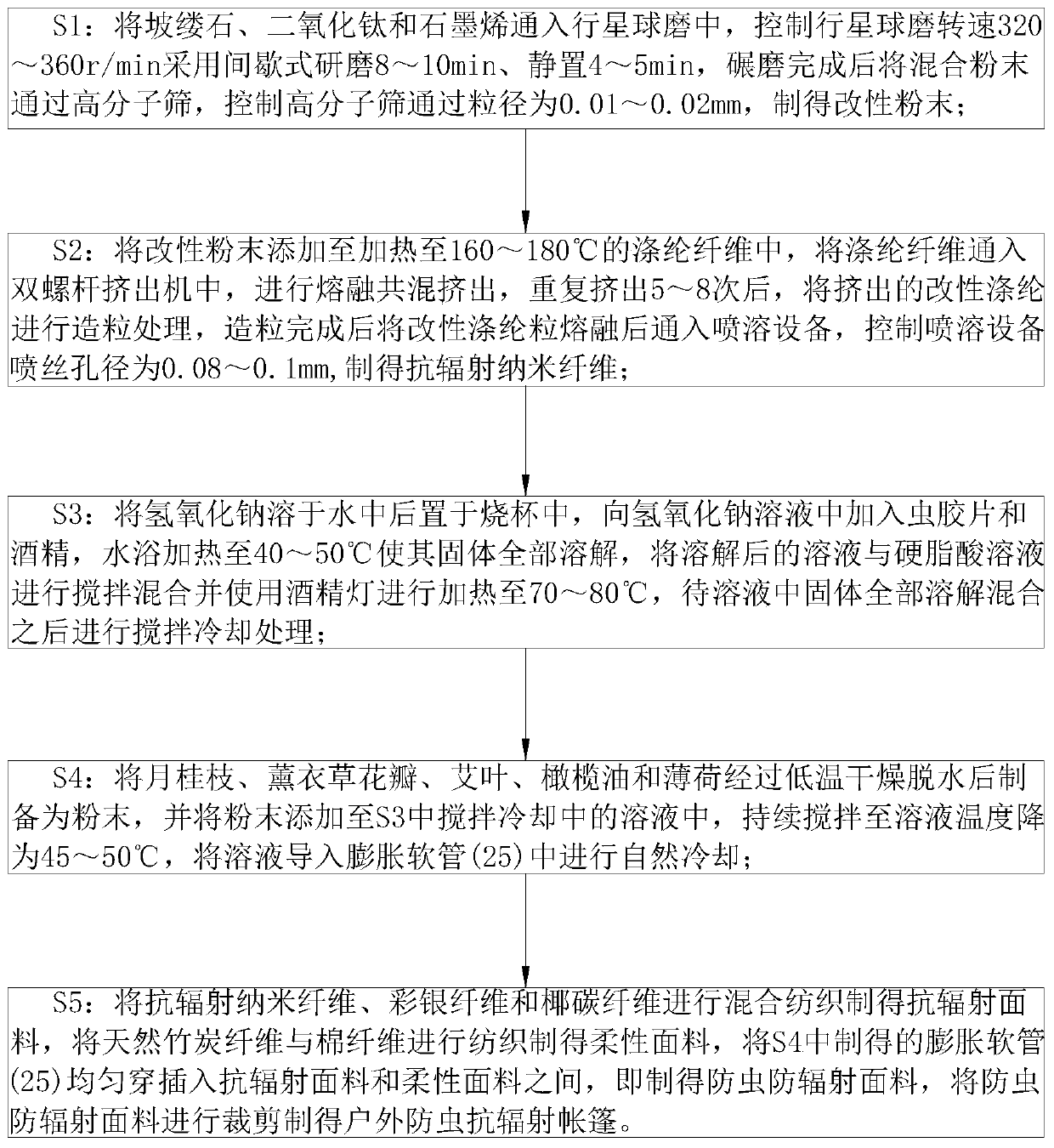

[0036] A preparation process of an insect-proof and radiation-proof fabric, the preparation process comprising the following steps:

[0037] S1: Pass palygorskite, titanium dioxide and graphene into the planetary ball mill, control the speed of the planetary ball mill at 320-360r / min, use intermittent grinding for 8-10 minutes, and stand still for 4-5 minutes. After the grinding is completed, pass the mixed powder through high-speed Molecular sieve, the polymer sieve is controlled to pass a particle size of 0.01-0.02mm, and the modified powder is obtained; palygorskite, titanium dioxide, and graphene are ground together, and high-speed grinding is carried out in a planetary ball mill, so that the mixture between High-speed friction generates high temperature, so that palygorskite, graphene, and titanium dioxide crystallize each other, so that the three components in the final milled mixed powder are more evenly mixed;

[0038] S2: Add the modified powder to the polyester fiber...

Embodiment approach

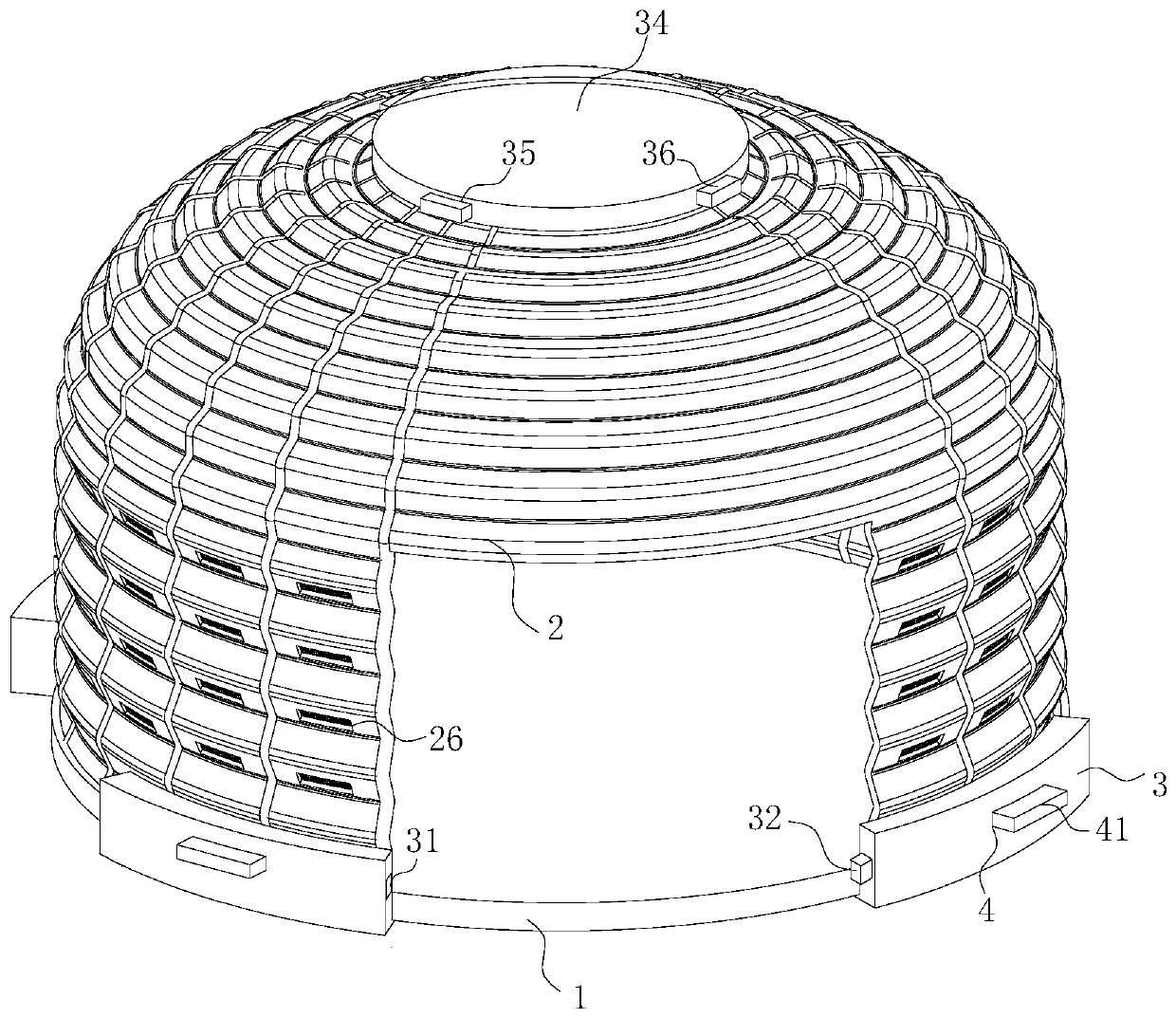

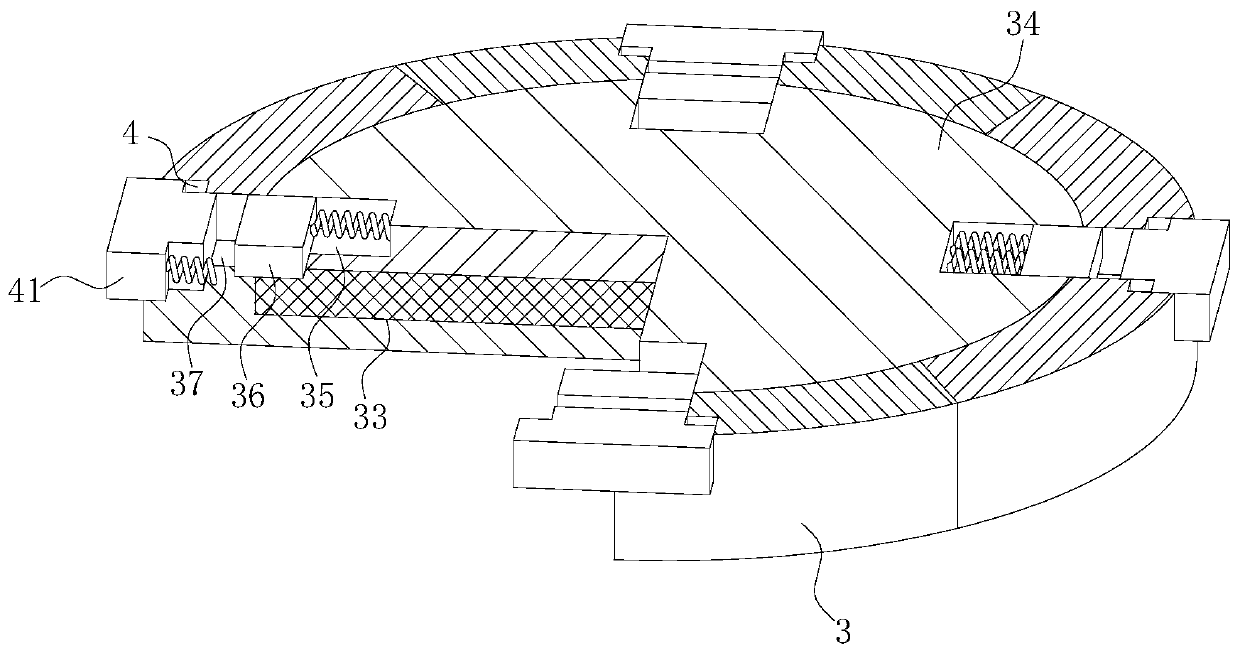

[0044] As an embodiment of the present invention, evenly distributed storage blocks 3 are fixedly connected to the edge of the base 1 away from the expansion surface 2; the number of the storage blocks 3 is four and they are fan-shaped; the storage blocks 3 are located at One side of the radial direction is provided with a card slot 31, and the other side is fixedly connected with a card block 32; and the two adjacent storage blocks 3 on the opposite side are compatible with the card slot 31; the upper surface of the storage block 3 A storage slot 33 is provided; the storage slot 33 is fixedly connected to the base 1; the expansion surface 2 is located at the top and is fixedly connected with a fixed plate 34; the fixed plate 34 has a circular design; the side of the fixed plate 34 is provided with Evenly distributed grooves 35; the grooves 35 are elastically connected with a fixed block 36; the fixed block 36 is designed in an arc shape near the side of the storage block 3; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com