A breathing self-driven micro-flow sensor based on lever principle and its preparation method

A lever principle, self-driven technology, applied in the direction of sensors, evaluation of respiratory organs, induction generators, etc., can solve the problems of inconvenient detection of small flow, condensation and formation of dielectric layers, etc., and achieve low cost, small flow change, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

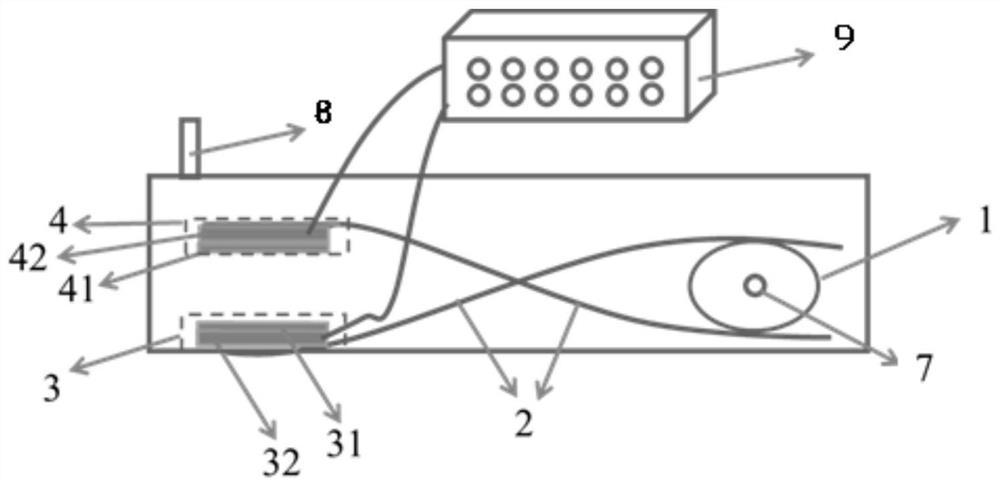

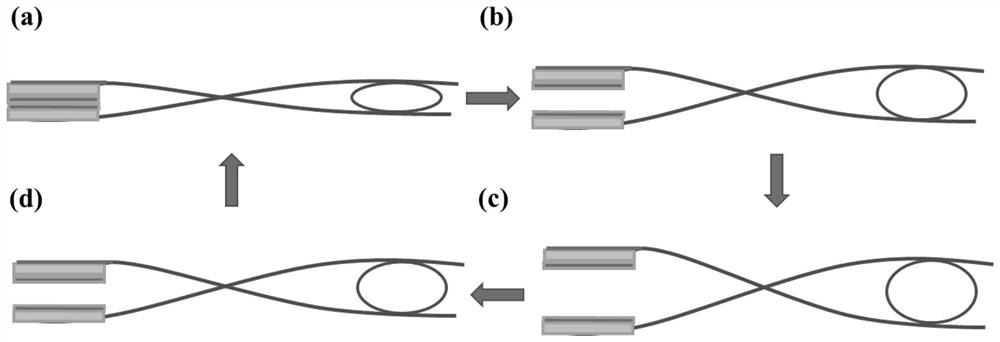

[0034] like figure 1 Shown: a breathing self-driven micro-flow sensor based on the lever principle, including a packaging cavity, an air outlet conduit 8 communicating with the packaging cavity, and a power generation unit and a flow collection unit arranged in the packaging cavity. The power generation unit includes a first friction Unit 3 and the second friction unit 4, two pieces of flexible organic film elongated substrates 2 are intersected in the package cavity to form a laborious lever, and the intersection forms a fulcrum; the ends of the long levers far away from the fulcrum are respectively provided with the first A friction unit 3 and a second friction unit 4, the end of the short lever near the fulcrum is provided with a flow collection unit, the flow collection unit is made up of the air intake conduit 7 communicated with the balloon 1, the balloon 1 and the short lever Fixed connection at the end;

[0035] When the air flow passes through the balloon 1, it will ...

Embodiment 2

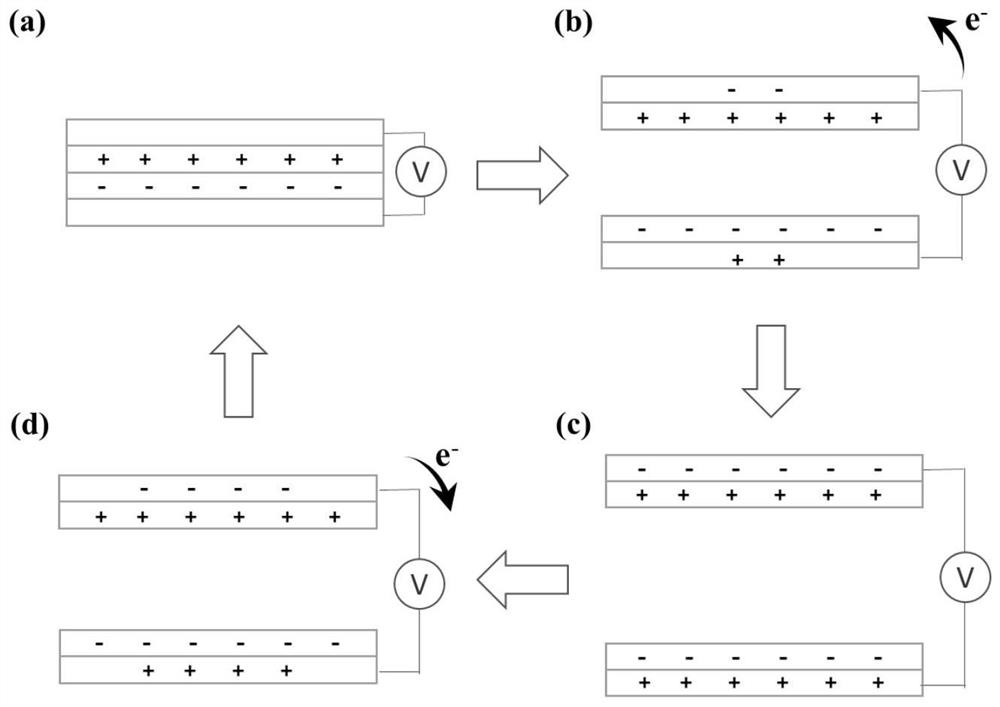

[0040] On the basis of Example 1, the first friction unit 3 includes a conductive electrode and a positive friction film 31 arranged in sequence at the end of the long lever, and the positive friction film 31 is one of nylon, silk, polyurethane foam, and paper or a composite film made of it. The second friction unit 4 includes another conductive electrode and a negative friction film arranged at the end of the long lever in sequence, and the negative friction film is one of polydimethylsiloxane, Teflon, and polytetrafluoroethylene or a composite film made of it.

[0041] Further, the material of the conductive electrode is any one of aluminum, nickel, copper, silver and gold; the thickness of the electrode is 100-200nm.

Embodiment 3

[0043] like Figure 4 As shown, on the basis of Embodiment 1 or 2, a breathing self-driven micro-flow sensor based on the lever principle also includes a fourth friction unit 6 arranged on the upper or lower surface of the packaging cavity, and the fourth friction unit 6 The third friction unit 5 on one side of the corresponding lever, wherein the second friction unit 4 and the third friction unit 5 are attached to the opposite surface of the same lever, and the whole device forms a three-layer sandwich structure; the third friction unit 5 is composed of The substrate, the conductive electrode, and the negative friction film are composed of stacked layers, and the fourth friction unit 6 is composed of the substrate, the conductive electrode, and the sensitive film 61 that are stacked in sequence; The electrodes are connected to another electrometer 9 by wires.

[0044] The data of the two devices are processed through different structural compensation related sensor knowledge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com