RuCo alloy catalyst, preparation method thereof and application thereof in ammonia synthesis

An alloy catalyst and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, preparation/separation of ammonia, etc., can solve the problems of huge energy consumption and very large dissociation requirements, and achieve high ammonia synthesis reaction rate , High utilization rate, high atomic dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] According to the present invention, also provides a kind of preparation method of RuCo alloy catalyst for ammonia synthesis, comprises the following steps: 1) take melamine, Ru precursor and Co precursor and dissolve in dimethyl sulfoxide (DMSO) solution, obtain mixed solution , ultrasonicating the mixed solution; 2) dissolving cyanuric acid in the DMSO solution, ultrasonicating; 3) slowly pouring the mixed solution obtained in step 2) into the mixed solution obtained in step 1), stirring, suction filtering, and Washing with dehydration and ethanol solution successively, drying and raising the temperature under an inert atmosphere, and calcining to obtain the RuCo alloy catalyst.

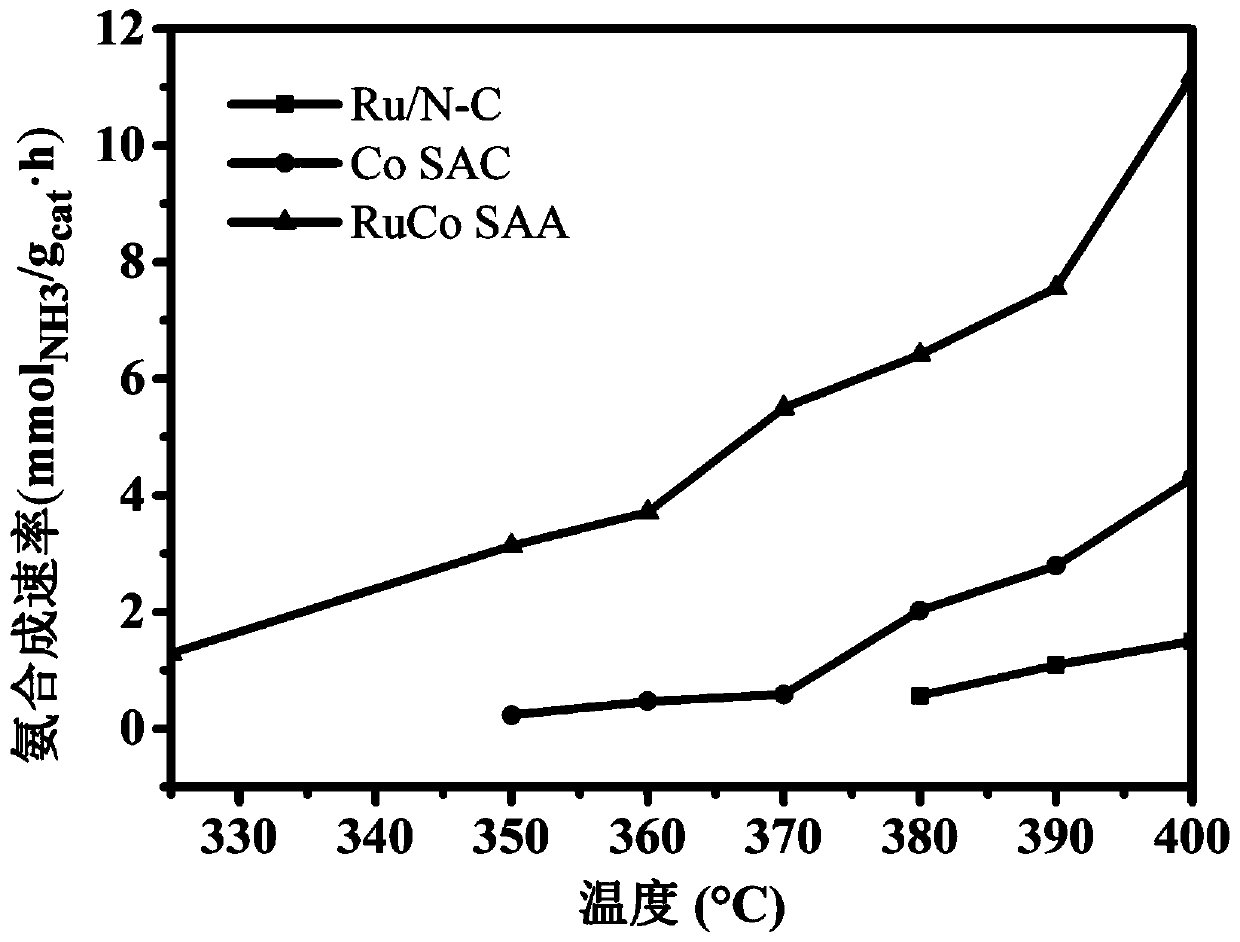

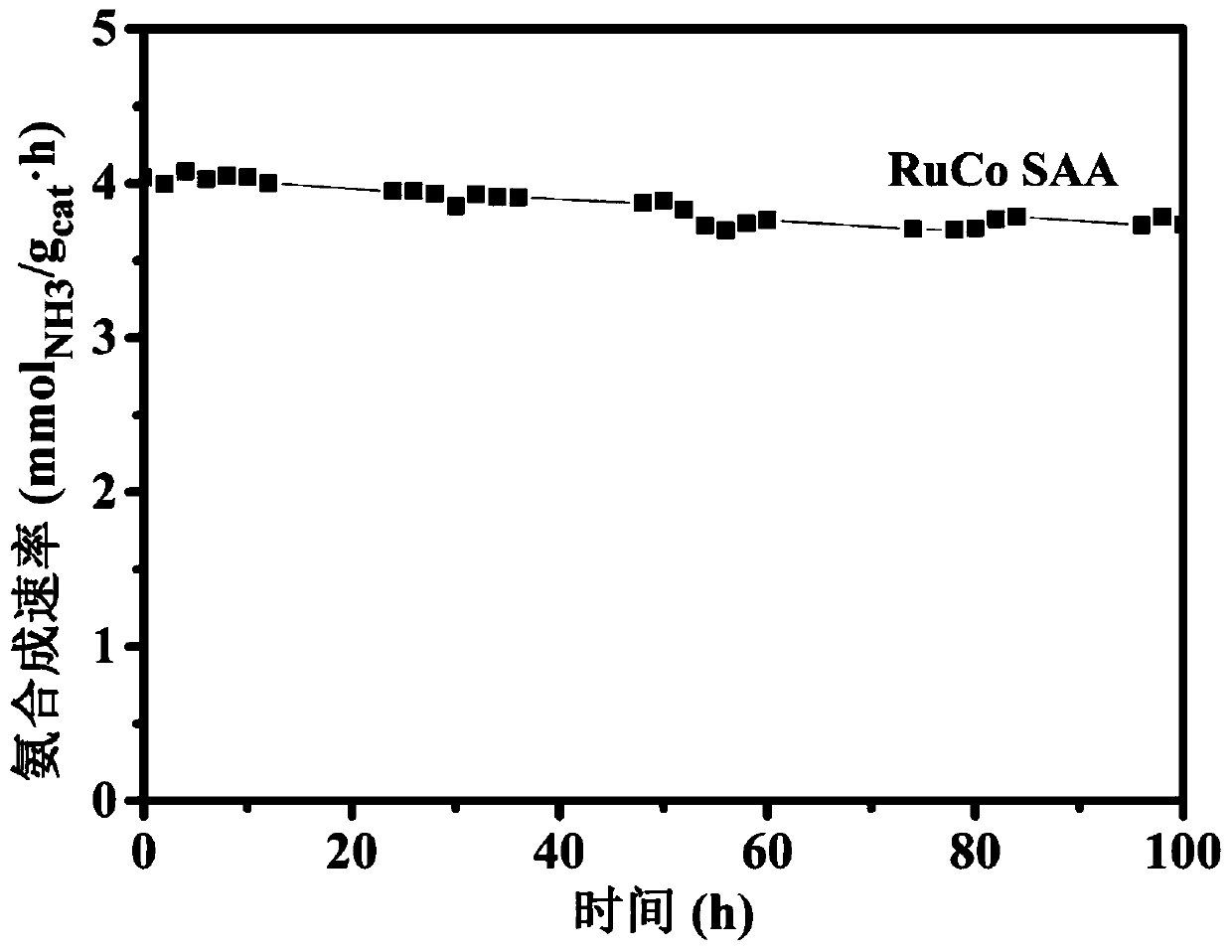

[0027]The invention synthesizes a highly dispersed RuCo alloy single-atom catalyst, which can break the restrictive relationship in the reaction process of the current ammonia synthesis catalyst. The prior art is N 2 Dissociate and adsorb on the metal surface, and then gradually hydrogenate ...

Embodiment 1

[0037] 1) 0.5g melamine (C 3 h 6 N 6 ), 0.201g cobalt phthalocyanine, and 0.35mL ruthenium nitrosyl nitrate solution were dissolved in 40mL DMSO solution, and the mixed solution was sonicated for 10 minutes.

[0038] 2) 0.51g cyanuric acid (C 3 h 3 N 3 o 3 ) was dissolved in 10 mL of DMSO solution, and ultrasonicated for 10 min.

[0039] 3) Slowly pour the solution obtained in step 2) into the solution obtained in step 1), stir at a rate of 600r / min for 10min, filter with suction, wash with 150mL deionized water and 100mL ethanol solution, and place the washed sample at 60°C Let dry for 12 hours.

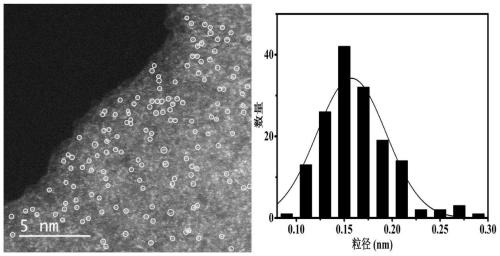

[0040] 4) The dried sample was heated up to 600 °C at a rate of 1 °C / min in an Ar atmosphere and kept for 8 h to obtain a RuCo alloy single-atom catalyst supported by nitrogen-doped carbon, labeled as RuCo SAA.

[0041] The ICP-AES (Inductively Coupled Plasma-Atomic Emission Spectroscopy) method is used to measure that the Ru loaded in the embodiment is 0.34%, and the Co is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com