Normal-pressure synthesis method of SAPO-11 molecular sieve

A technology of SAPO-11 and atmospheric pressure synthesis, which is applied in the direction of molecular sieve and alkali exchange phosphate, molecular sieve characteristic silicoaluminophosphate, etc., can solve the problems of complex synthesis method and high synthetic composition, and achieve the improvement of isomerization reaction activity and synthesis The method is mild and accelerates the effect of nucleation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

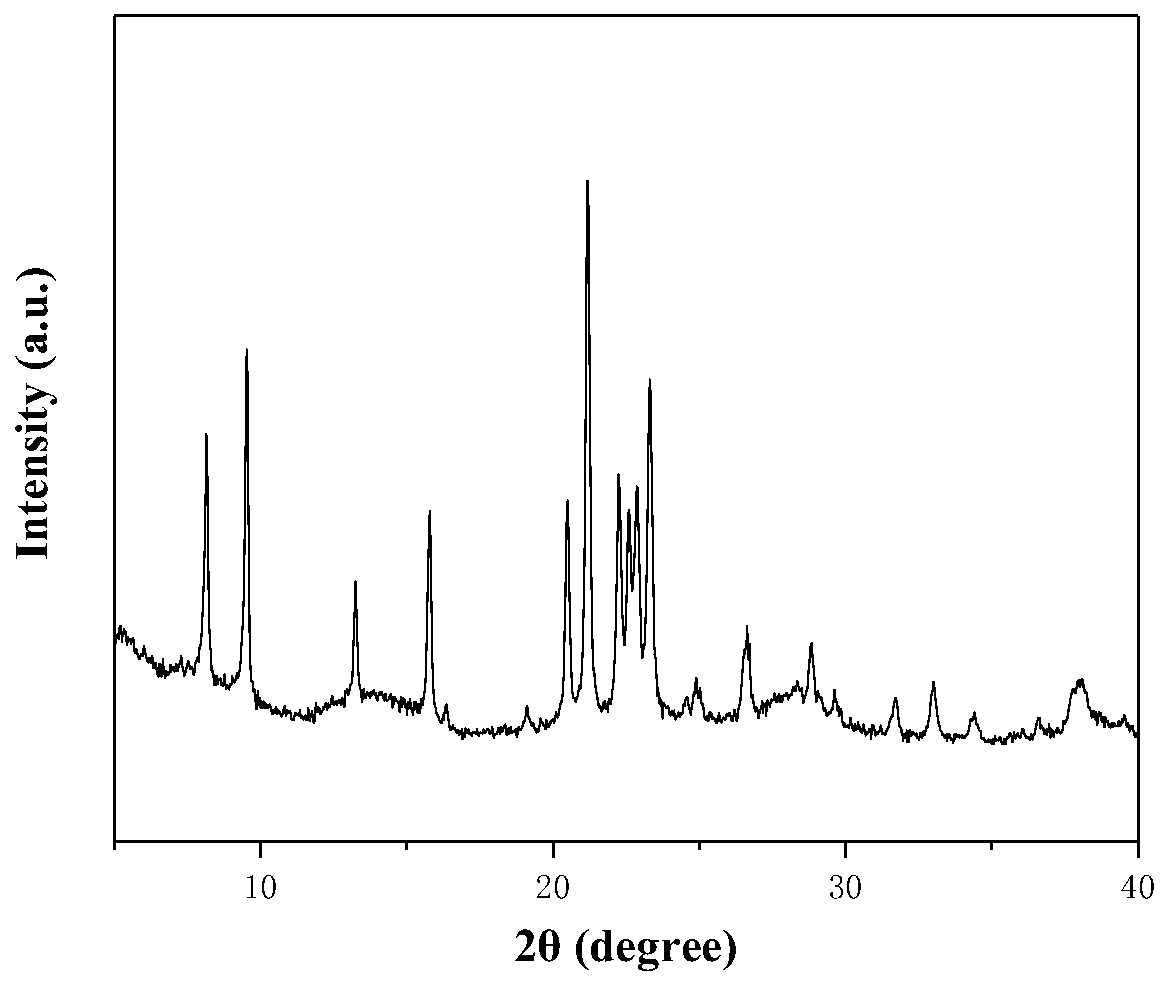

[0022] According to deionized water, boehmite (with Al 2 o 3 In terms of), phosphoric acid (in P 2 o 5 ), organic amine di-n-propylamine, silica sol, and biochar in a molar ratio of 90:1.0:1.0:1.1:0.4:0.10 were sequentially added into the beaker, stirred for 8 hours to obtain a crystallization precursor, and the resulting crystallization precursor was transferred to In the crystallization kettle, under the condition of microwave power of 600w, after crystallization at 100°C for 8h (operating pressure is 10100pa), the crystallized product is obtained; it is washed and washed with deionized water whose quality is 4 times that of the crystallized product Filter, then dry at 100°C for 6h, and roast at 650°C for 8h, perform X-ray diffraction on the SAPO-11 molecular sieve with AEL structure, and analyze its diffraction pattern XRD, see figure 1 ,From figure 1 It can be seen that the synthesized product has the characteristic diffraction peak of SAPO-11 molecular sieve.

Embodiment 2

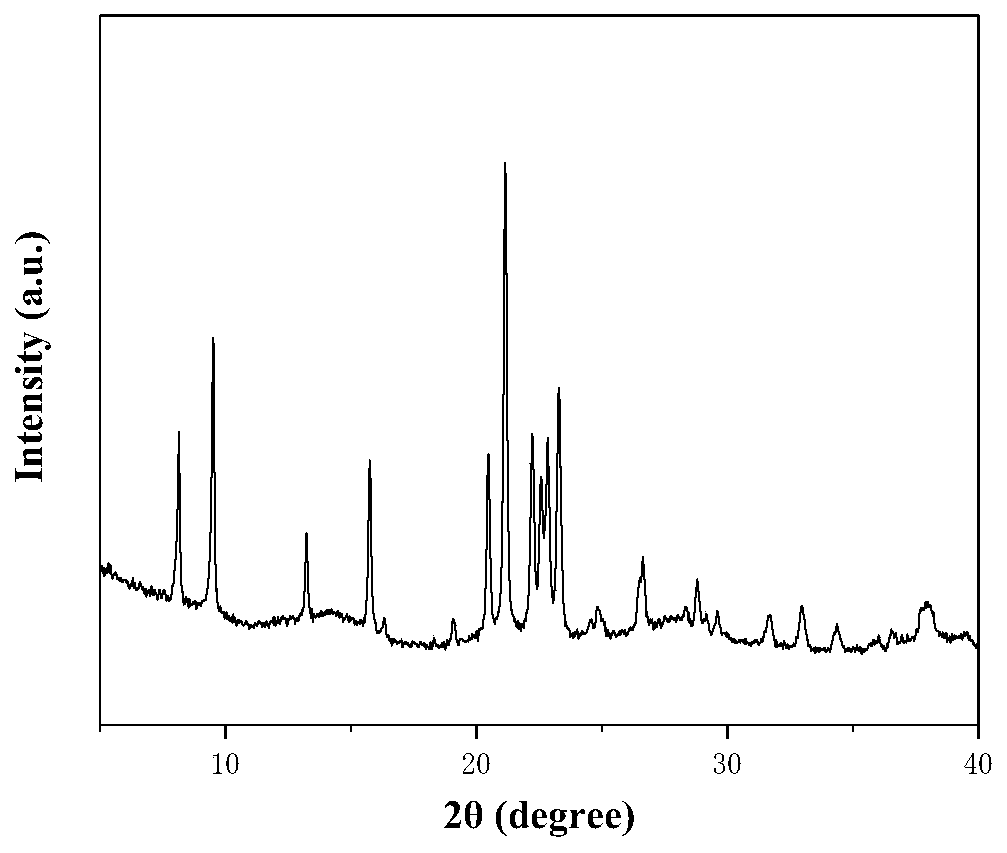

[0024] According to deionized water, boehmite (with Al 2 o 3 In terms of), phosphoric acid (in P 2 o 5 According to the molar ratio of 90:1.0:1.0:1.1:0.4:0.03:0.20, the organic amine di-n-propylamine and diisopropylamine, silica sol, seed crystal SAPO-11 molecular sieve powder and biochar were sequentially added into the beaker, Wherein the organic amine is a mixture of di-n-propylamine and diisopropylamine, and the mass ratio of the two in the mixture is 50%:50%. After the above solution is fully stirred for 6 hours, the crystallization precursor is obtained, and the crystallization precursor is transferred to the crystallization kettle. , under the condition of microwave power of 400w, after crystallization at 90°C for 12h (operating pressure is 10000pa), the crystallization product was obtained; it was washed and filtered with deionized water whose quality was 4 times that of the crystallization product, and then at 90 ℃ for 8 hours, then roasted at 550 ℃ for 6 hours, X-...

Embodiment 3

[0027] Deionized water, aluminum isopropoxide (as Al 2 o 3 In terms of), phosphoric acid (in P 2 o 5According to the molar ratio of 60:1.0:1.0:1.1:0.2:0.03:0.01, the mixture of diisopropylamine, silica sol, seed crystal seed SAPO-11 molecular sieve former powder and acetylene black, activated carbon is added into the beaker in order, and the above The solution was fully stirred for 2 hours to obtain a crystallization precursor, which was transferred to a crystallization kettle, and crystallized at 80°C for 4 hours under the microwave power of 200w (operating pressure was 10000pa), to obtain a crystallization product; The crystallized product was washed with deionized water twice the mass, filtered, dried at 80°C for 6 hours, and calcined at 450°C for 4 hours to obtain the SAPO-11 molecular sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com